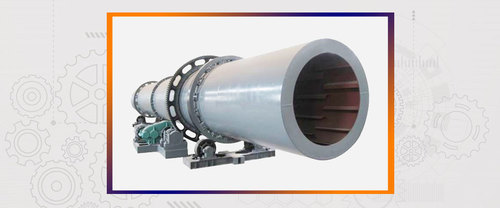

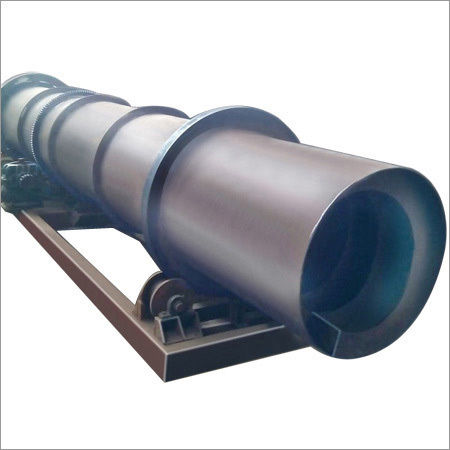

Continuous Type Rotary Dryer

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | Variable |

| Capacity | Variable |

| Rotation Speed | Variable |

| Heating Method | Direct |

| Power | Variable |

| Exhaust System | Included |

| Features | Long Life, Reliable, Abrasion Resistant, Mixes And Dries, Continuous Production, Direct Heating, High Efficiency, Low Fuel Consumption |

Product Overview

Key Features

Being a quality focused organization, we are engaged in manufacturing and exporting premium quality Continuous Type Rotary Dryer. We make these batch dryers at our sound manufacturing unit by using high grade raw material and modern machinery. Extensively used in minerals, chemicals, food, and pharmaceutical industry, this dryer is mostly used where high moisture percentage is available in wet material. Moreover, this Rotary Batch Dryer has the ability to both mix and dry in one unit.

Features:

- Longer service life

- Reliable performance

- Resistance against abrasion

Further Details

Drying is the process of removing moisture/combined water from wet material through heating. Umatech Micron's batch type and continuous (kiln) type dryers are widely used in minerals, chemicals, Food, and pharmaceutical industries.

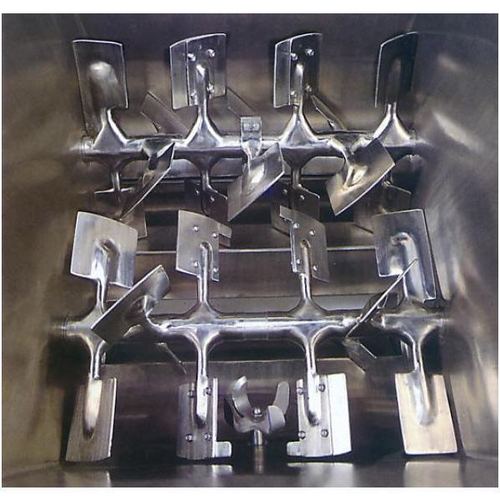

Umatech Continuous (Kiln) type dryer is typically used in the application of when direct heating to wet material and continuous production is required. Material particle is heated through direct contact of hot air or gases, which is passed along the length of the Dryer(Kiln), dt eliminating the heat losses and fuel consumption that is being used in heating the dryer vessel like in batch type dryer.

The selection of the right drying process and dryer design depends on the nature of the materials to be handled here our extensive processing know-how can help ensure customers to select the right equipment for the job; whether that be for the production of a few kilos or multi tonne lots.

Company Details

Focusing on a customer-centric approach, Peridot Jewelleries has a pan-India presence and caters to a huge consumer base throughout the country. Buy Plant & Machinery in bulk from Peridot Jewelleries at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

10

Establishment

2011

Working Days

Monday To Sunday

Payment Mode

Cash Advance (CA), Cash in Advance (CID)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Ahmedabad, Gujarat

Partner

Mr. Ketan Patel

Address

Plot No. C-103, Maruti Industrial Estate, Nr. Kiran Ind., Phase-1, G.I.D.C., Vatva, Ahmedabad, Gujarat, 382413, India

rotary dryer in Ahmedabad

Report incorrect details