Continuous Spiral Fin Coils

Price:

Get Latest Price

In Stock

Product Specifications

| Materials | Steel,Copper,Stainless Steel |

| OD | 8-50mm |

| Fin Spacing | 20-10 fins/inch |

| Fin OD | 20-88mm |

| Coil Length | Customizable |

| Fin Height | Customizable |

| Weight | Varies by size |

| Features | High Efficiency, Durable Design, Cost Savings, Easy Installation, Customizable Sizes, Improved Aesthetics, Rapid Production |

Product Overview

Key Features

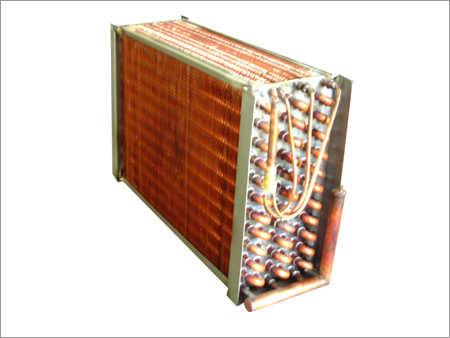

Since our inception in the year 1993, we are actively indulged in manufacturing and supplying vast gamut of Continuous Spiral Fin Coils, which are precisely designed using finest quality mild steel, stainless steel and copper. The offered coils are widely used for industrial electrical air fin heaters and air compressor cooling tubes. We are providing these Continuous Spiral Fin Coils in varied sizes and thickness and can be customizes as per the requirements of patrons.

Features

- Crimped fin design

- Increased heat transfer efficiency

- Highly durable

Continuous Spiral Fin Coils for Heaters

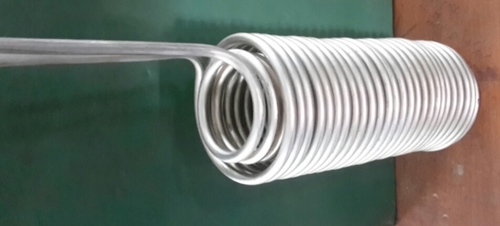

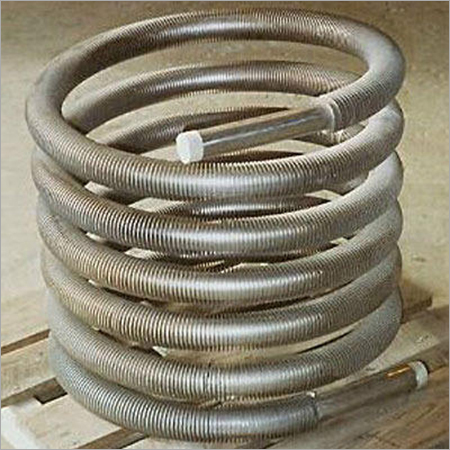

We have developed, continuous spiral fins without tube. I.E. fin coil specially for shaped or any other odd fabricated shaped tube. These are widely used for industrial electrical air fin heaters and air compressor cooling tubes. These coil replace the old fashioned, washer type. Separate fins. instead of putting separate one by one single washer fin, they they can put about 200 fins at time, using our continuous coil of fins. By this more fin heater can be made lesser time. Thus saving substantially on labour cost. Because of uniform spacing on fins, tubes tied with these coils have a very appealing get up. More over total heat transfer efficiency increase substantially because of continuous crimped fin design. Fin coil have been well received by heater manufacturers & Users. These fin coils are made according to the OD of the tube with fractional differences. Coils suitable for tube ODS., In Mm 8, 8.3, 8.5, 8.6., 9, 9.2, 9.5, 10, 11, 11.5, 12, 12.5, 12.7, 13, 14, 15, 16, 17, 19, 22, 25, 27, 28 and above any size Upto 50mm. Fin out slide diameter Min. 20 to Max. 88mm. (Depending On The Tube OD.) Fin spacing: From 20 To 10 fins per in inch. Material mild steel., Stainless steel and copper. Selected raw materials, strict adherence to specification, quality assurance, Best workmanship.

Company Details

Focusing on a customer-centric approach, OM SAI ENGINEERING INDUSTRIES has a pan-India presence and caters to a huge consumer base throughout the country. Buy Coils in bulk from OM SAI ENGINEERING INDUSTRIES at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Establishment

1993

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Mumbai, Maharashtra

Proprietor

Mr. Ankush Naik

Address

Raigad Chawal, Ambewadi, LBS Marg, Vikhroli (W), Mumbai, Maharashtra, 400083, India

finned coils in Mumbai

Report incorrect details