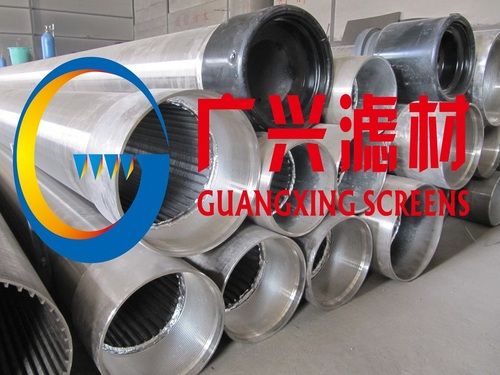

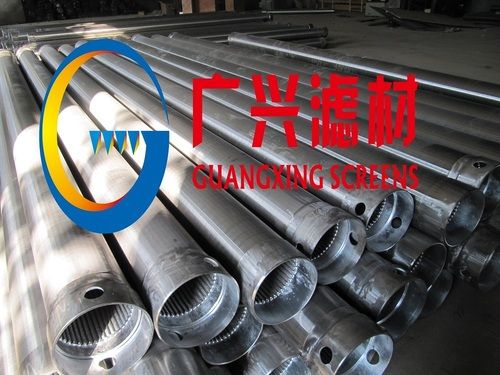

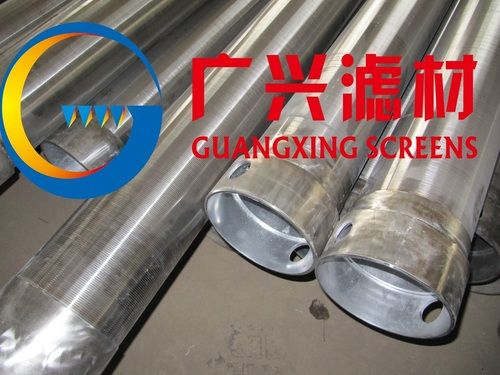

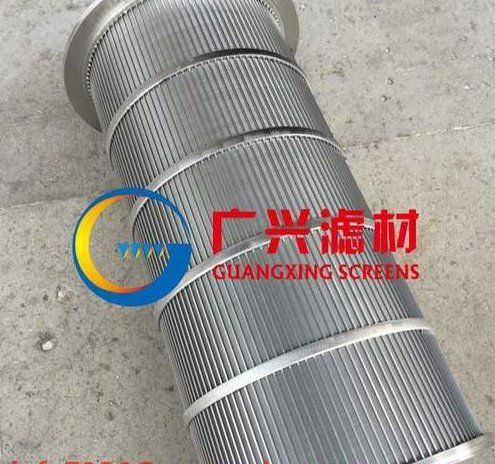

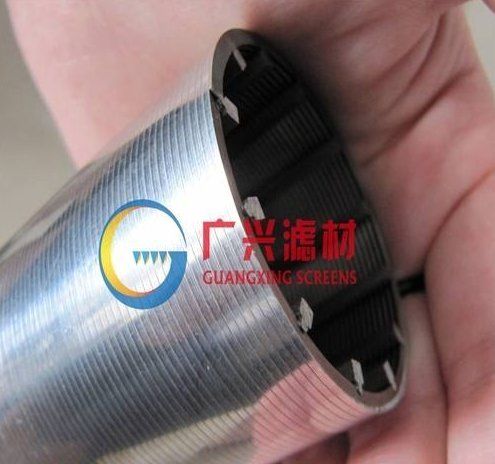

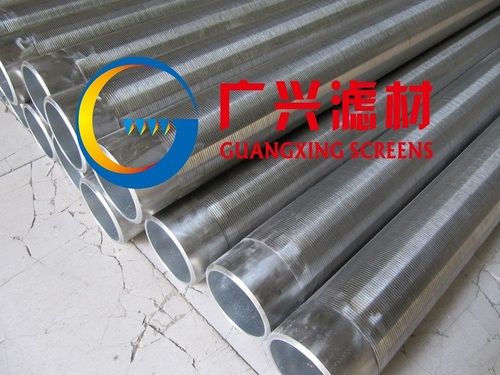

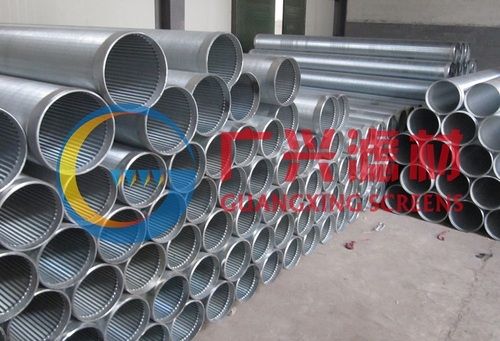

We are exporting of Continuous Slot Screen to our consumers. This is Sandra from guangxing screen company.We are a manufacturer of continuous slot wedgewire well screen in china. The wedgewire products are manufactured by rolling a V-Shape wire around an internal framework of longitudinal bars. The external V-Shape wire can have either a sharp end, in what is known as Vee-Wire Sharp, or it can have a round end in what is known as a Vee-Wire Wear. Depending on the type of wire used and the slot opening, the open area of a wedgewire screen can vary between 10% and 70% of the total area (see graph). The average opening area of a water well screen varies from 35% to 45% compared with 5% to 15% on average of a other screens (e.g. perforated or bridge screen). In the case of support grids, the filtering area can be up to a 70% of total area, depending on the material used and the slot.The continuos slot water screen has several advantages compared to other screens such as bridge slot screen or perforated screen. A larger opening (filtering) area of a wedgewire screen leads to superior performance of a water well compared against the installation of other types of screens. Moreover a wedgewire filter for water well are self-cleaning (go-no go), thus, prevents losses due to friction as well as losses associated with pumping sand. Also, a continuous slot wedgewire water well screen eliminate the problems associated with fine sands, thus, increasing the life of the pumping equipment.