Conlite- Construction Grade

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Perlite concrete |

| Density | 320-640 kg/m3 |

| Compressive Strength | Variable |

| Thermal Conductivity | 0.07-0.12 W/m.K |

| Fire Rating | 3 hour |

| Thickness | Variable |

| Application | Roofing, wall filling |

| Features | Lightweight, Insulating, Fire resistant, Soundproof, Durable, Cost-effective, Versatile |

Product Overview

Key Features

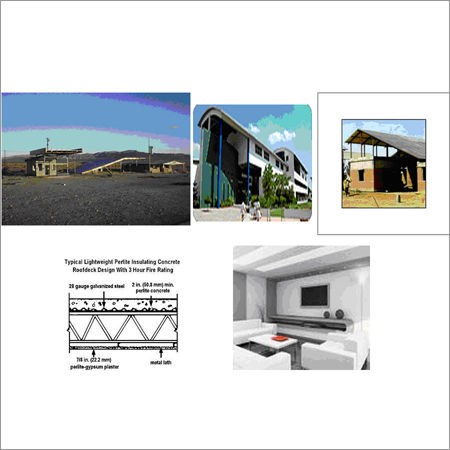

Conlite (Construction grade of Light weight Insulating concrete Roof Decking-Wall filling and green building Application with Perlite plaster Interior and exteriors and Terrace Gardens)

Conlite (concrete) is a perlite based organic mineral based on the coating available. Perlite concrete aggregate combined with cement and water produces a lightweight insulating concrete used for lightweight roof decks, floor fills, lightweight structural decks, insulation for steam and coolant lines lightweight pre-cast forms and blocks, statuary, basic fills, and many other applications. The physical properties of perlite concrete vary according to mix designs. Perlite concrete can be made with a dry density of 20 lb/ft3 (320 kg/m3) or with the addition of sand or other aggregates up to 90 lb/ft3 (1440 kg/m3). The lower the density, the higher the insulating value.

Roofing Insulation

Conlite concrete has superior wind and fire resistance over other roof insulation materials and with the addition of polystyrene insulation board sandwiched in the perlite concrete, high thermal resistance values are economically achieved.

Positive drainage is easily accomplished by varying the thickness of perlite concrete or by stair stepping different thicknesses of polystyrene insulation board and then covering it with a uniform layer of perlite concrete. Perlite concrete insulation may be placed over vented or slotted galvanized steel decking, precast or pour-in-place concrete or existing roofing materials providing a seamless, smooth, and hard surface ready for roofing. If exposed to water it will not deteriorate.

Re-Roofing Base

Conlite concrete insulation is ideally suited for reroofing applications. It provides permanent, cost effective, slope-to-drain designs with high R-values over flat and often-irregular substrates found in reroofing projects.

Perlite Concrete Lightweight Sound-Deadening Concrete

Excellent sound deadening lightweight concrete can be installed without special foaming equipment using materials readily available at most building material dealers. For smaller jobs, materials can be job mixed and placed by any type of plaster or grout pump.

Class | Aggregate | Weight (kg/m3) | "K"(W/m/C) |

Light weight | Perlite | 320-640 | 0.07-012 |

Medium | Slag, shale, clay, pumice | 960-1520 | 0.24-0.75 |

Heavy | Sand & gravel | 2240-2400 | 1.30-1.73 |

Standard Specification for Lightweight Aggregates for Insulating Concrete (Significant parts of ASTM C-332, Group I) | |||

Basic Specifications | Density | Sieve Analysis Weight ( Percent Passing Each Sieve) | |

PERLITE | 120 to 196 kg/m3 | 9.5mm | ..... |

4.75mm | 100.00% | ||

2.36mm | 85 to 100% | ||

1.18mm | 40 to 85% | ||

600 microns | 20 to 60% | ||

300 microns | 5 to 25% | ||

150 microns | 0 to 10% | ||

Table 1. TYPICAL PROPERTIES OF PERLITE CONCRETE

lbs/ft' kgtm | lbs/In7 kg/m | lbs/in' kpa | lbs/in1 kpa | Wet Density When Placed lbs/ft1 Kg/m |

350 2413 | ||||

230 1585 | ||||

140 965 | ||||

80 552 |

Cement/ Aggregate Ratio by Volume | Oven Dry Density |

| Dry Density Range |

| Compressive Strength Range | Minimum Compressive Strength |

| Wet Density When Placed |

| |

lbs/in2 Kpa | lbs/ft2 | Kg/m3 | Lbs/ln2 | Kg/m3 | Lbs/ln2 | kpa | Lbs/ln2 | kpa | Lbs/ft3 | Kg/m3 |

01:04:00 AM | 36 | 576 | 34.0-40.0 | 544-640 | 350-500 | 2413-3447 | 350 | 2413 | 50.5+2.0 | 808.0+32.0 |

01:05:00 AM | 30.5 | 488 | 28.0-34.0 | 448-544 | 230-340 | 1585-2344 | 230 | 1585 | 455+20 | 728.0+320 |

01:06:00 AM | 27 | 432 | 24.0-280 | 384-448 | 140-200 | 965-13/8 | 140 | 965 | 40 5+20 | 648.0+32.0 |

01:08:00 AM | 22 | 352 | 20.0-34.0 | 320-384 | 80-125 | 552-861 | 80 | 552 | 36.5+2.0 | 584.0+32.0 |

PERLITE BASAED PLASTER

Laboratory and field tests have proven perlite, conlite and sand concrete is suitable for use over structural forms such as corrugated steel, rib steel or cellular steel floor units and plywood sub-floors and ideal as a base for a wide variety of floor materials including carpet, tiles and hardwoods. Perlite based plaster has endless unique properties accounting for its ready acceptance and widespread use by many leading architects, general contractors and plastering contractors.

Advantages

- Lightweight: Conlite plaster is only one third the weight of sanded plaster. Lightness in weight also permits the plasterer to maintain his optimum production for the full working day with much less effort.

- Fireproofing: National bodies have been swift to recognize the advantages of superior fire protection and potential cost reductions afforded by Perlite/plaster fireproofing and have modernized codes to take full use of this. Fire tests at the underwriter's laboratories have resulted in ratings as high as 4 hours for plaster containing Perlite.

- Insulating: Perlite possesses millions of tiny air particles and in turn permanent insulation cavities that reduce heat transmission losses. Perlite adds a high thermal insulation value to plaster.

- Better Workability: Its sharpness has similar workability to that of sand. Plasterers because of its ease of handling and simplicity appreciate it.

- Crack Resistant: Perlite/plaster has a high degree of resiliency ensuring less cracking.

- Base Coat Plaster: Perlite is an ideal aggregate for all general (base coat) plastering. On many jobs, it costs no more than ordinary sand plaster. It mixes with both gypsum plaster and cement for the scratch and brown coats.

- Acoustics: Perlite acoustic plaster is an efficient, economical and attractive sound absorbent plaster that can be handled by any skilled laborer. It can be washed and redecorated, is of proper hardiness, and can withstand normal wear and tear without dusting and disintegration.

Company Details

Focusing on a customer-centric approach, Perl Tech has a pan-India presence and caters to a huge consumer base throughout the country. Buy Heat Insulation in bulk from Perl Tech at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

6

Establishment

2006

GST NO

24AAEHG5890G1Z8

Related Products

More Product From This seller

Seller Details

GST - 24AAEHG5890G1Z8

Ahmedabad, Gujarat

Accepts only Domestic inquiries

Proprietor

Mr. Gautam Patel

Address

4th Floor, Laxmi Chamber, Navjeevan Press Road, Income Tax, Ahmedabad, Gujarat, 380014, India

Heat Insulation in Ahmedabad

Report incorrect details