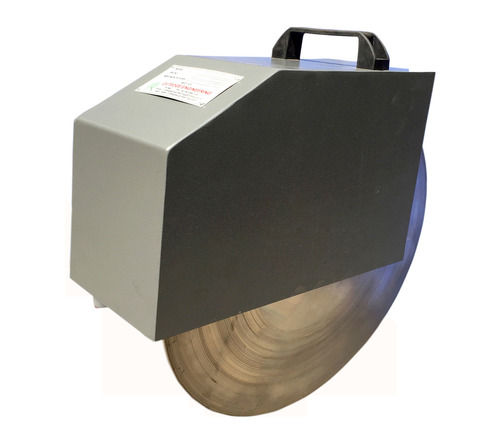

Compact Band Filter System

Price: 1 INR / Piece

Get Latest Price

Minimum Order Quantity :

1 Piece

In Stock

Product Specifications

| Body Material | MS/SS |

| Operation | Automatic |

| Coolant Supply | Gravity/Pump |

| Filter Paper | Fitted Top |

| Limit Switch | Lever Type |

| Mesh Drive | Sprocket Fitted |

| Dust Collection | Dust Bin |

| Features | Compact Design, Lesser Consumption, Removes Impurities, Automatic Operation, Easy Maintenance, Hassle Free |

Product Overview

Key Features

Compact design occupies lesser space without compromising the efficiency

Lesser consumption of the filter paper

Removes ferrous and non-ferrous impurities

Diffuser box to reduce velocity of the coolant

Fully automatic operation - Float switch sensor to remove clogged filter paper. Float switch sends a signal to control panel to activate the electric drive.

Lever type limit switch is adjusted on paper filter role and gets activated when paper role gets consumed. Limit switch sends a signal to Control panel to flash a warning when activated.

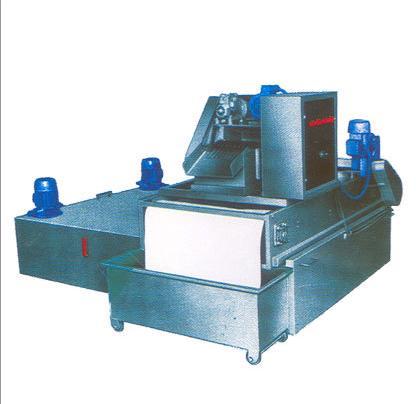

Designed as per requirement in MS or SS body and available for standalone machine as well as for centralized filtration system.

Uses gravity or supply pump depending on application

Easy maintenance

Hassle free installation.

Operation:

Suitable filtration paper role is fitted at the top of compact band filter and is guided through Honeycomb mesh and sealing Drum assembly. Lever type Limit switch is placed on top of filter paper in such manner that it gets activated at particular height when paper role gets consumed and sends a signal to control panel.

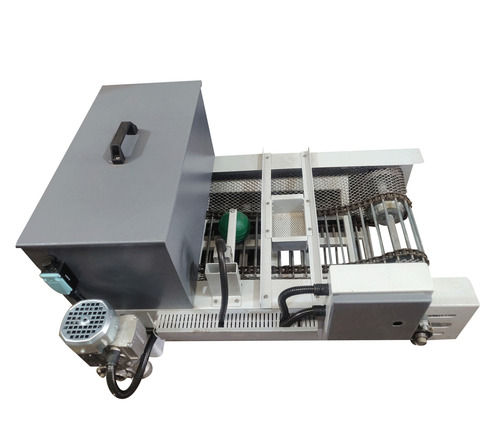

Honeycomb mesh is driven by a matching sprocket fitted on drive shaft on one end and rollers on the other end. Sealing is achieved by adjusting a gap between Drum Assembly and Honeycomb mesh using spring mechanism.

Float switch is fitted above the filter paper at the bottom of drum assembly.

Coolant from dirty tank is supplied to Diffuser box of Compact Band Filter using gravity feed or supply pump. The Diffuser box helps to reduce the velocity and spreads the coolant on top of the filtration paper.

The filter paper removes the impurities and coolant is filtered into Clean tank.

Over multiple cleaning cycles, a dirt cake gets formed on top of filter paper which activates the Float switch at predetermined height.

Float switch sends a signal to control panel to activate the electric drive. Once electric motor starts, filter paper is pushed out and the dirt cake gets collected in the dust bin which is placed on the side of clean tank.

Once the fresh filter paper is pushed on honeycomb mesh, float switch goes back to its original position and sends a signal to the control panel to stop the electric drive.

Reed proximity sensor fitted on clean and dirty tank helps to control the operation of supply and transfer pumps.

Company Details

Business Type

Manufacturer, Supplier, Retailer

Employee Count

20

Establishment

2015

Working Days

Friday To Wednesday

GST NO

27AAKFC4837H1Z9

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AAKFC4837H1Z9

Pune, Maharashtra

Mr Santosh Desai

Address

Plot No - 34/H and 34/I, Gat No 729, Jayawant Industrial Estate, Satara Road, At post Velu, Pune, Maharashtra, 412205, India

paper band filtration system in Pune

Report incorrect details