Commercial Electrodes

Price:

Get Latest Price

Minimum Order Quantity :

200

In Stock

Product Specifications

| Material | High Chromium |

| Carbon | High Carbon |

| Abrasion Resistance | Excellent |

| Temperature Resistance | Upto 500Oc |

| Deposition Efficiency | 98% |

| Application | Hard Surfacing |

| Operator Skill | Low Skilled |

| Features | High Performance, Easy Usage, Robust Construction, Optimum Performance, Low Maintenance, Reasonable Price, Wear Resistance |

| Payment Terms | Others |

| Delivery Time | 2 Months |

| Sample Available | Yes |

| Main Export Market(s) | Eastern Europe, Western Europe, Africa, Central America, Australia, Middle East, South America, Asia, North America |

Product Overview

Key Features

Backed by our years of experience and domain knowledge, we are involved in offering supreme quality Commercial Electrodes for Sugar Roller Roughening. It is widely appreciated for its high performance, easy usage and various other quality traits. Our team of skilled professionals fabricates these products with authentic quality raw materials in our state-of the-art manufacturing unit and each product is stringently checked on various quality traits before being made market ready for our clients.

- Robust construction

- Optimum performance

- Low maintenance

- Reasonable price

Characteristics & Applications :

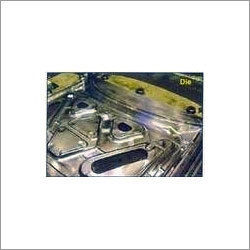

SUGARARC-60 is a high chromium high carbon-hard surfacing electrodes with excellent resistance to sliding abrasion. In addition to its superior abrasion resistance. It retains a high degree of wear resistance upto 500oC. The electrode deposits high alloy chromium carbide on the teeth of mill rolls. Which provides more resistance, increases the life of rollers.

Deposition Efficiency :

SUGARARC-80 is composite electrode where 98% of the core wire and coating alloys go into the weld, that there is very little slag produced.

Recommendation :

SUGARAC-80 Electrode is used for hard surfacing in the continuous arcing method-for severe abrasion and moderate impact applications. How ever for sugar roll roughening (Globular metal) the electrode should be used in a dot or broken are method similar to a brushing technique.

Roller Arcing :

The process of surface treatment of sugar mill feed rolls is the depositing of wear resistance can gripping globular points on the sides and tips of roll teeth. Arcing can be done while crushing is in process. The process of bonding/gripping points to the roll surface is carried out either during maintenance periods. Electrodes may be applied during the crushing process. The electrode is designed for his use. The frequency to deposit roll gripping points will vary with the actual operating conditions. Welding under dry conditions than welding under wet condition.

Benefits :

- Use of this electrode proves to be less costly, it provides a harder, more wear resistant deposit with a more favourable metallurgical structure. This electrode can be used while crushing is in process and cost of using this electrode will be insignificant as this increase crushing capacity.

- The surface are gained on the teeth of the roll (approx, 10%) gives more contact with the bagasse.

- The metal deposited reduces the wear on the actual mill rolls and Arcing can be done on the roll which are slipping and slip will stop.

- SUGARARC-80 increases the surface area which increases sugar extraction and production.

- SUGARARC-80 is manual metal are electrodes required low skilled operator. Without any training. So mi- skilled shall can be utilized

Company Details

Focusing on a customer-centric approach, ASIANARC ELECTRODES PRIVATE LIMITED has a pan-India presence and caters to a huge consumer base throughout the country. Get Welding Electrodes from ASIANARC ELECTRODES PRIVATE LIMITED at Trade India quality-assured services.

Business Type

Exporter, Manufacturer, Service Provider, Supplier

Employee Count

15

Establishment

1990

GST NO

09AAACA2863J1ZM

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 09AAACA2863J1ZM

Noida, Uttar Pradesh

Accepts only Foreign inquiries

Mr. Mukesh Khanna

Address

B-140, Sector-6, Noida, Uttar Pradesh, 201301, India

steel welding electrodes in Noida

Report incorrect details