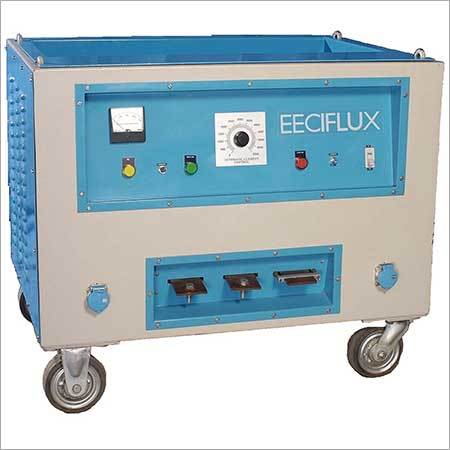

Coil-strip Ut System - Steel Construction, Blue Finish | Precision Flaw Detection For Industrial Applications

Price:

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Humidity | a%0$? 85% RH |

| Display Type | Digital (HMI/PLC) |

| Measuring Range | 0.5aEUR"50 mm |

| Product Type | Coil-Strip UT System |

| Frequency | 2aEUR"10 MHz (ultrasonic) |

| Hardness | Not Applicable (for base metal only) |

| Equipment Type | Ultrasonic Testing System |

| Material | Steel |

| Specimen Size | As per coil/strip dimension |

| Port Size | Standardized for industrial connections |

| Temperature | 5AdegC to 40AdegC |

| Response Time | < 1 sec |

| Max Height | Customizable as per plant requirement |

| Number of Specimens | Single or Multiple per batch |

| Interface Type | Ethernet/USB/RS232 |

| Power Supply | AC 220V/380V, 50/60 Hz |

| Usage | Industrial |

| Resolution | 0.01 mm |

| Accuracy | A+-0.1 mm |

| Color | Blue |

| Operating Voltage | 220V/380V |

| Automation Grade | Semi-Automatic/Automatic |

| Mounting Type | Floor Mount |

| Test Range | 0.5 mm aEUR" 50 mm (thickness) |

| Application | Non-destructive testing of steel coil and strip |

| Features | Auto-report, defect alarm, real-time data logging |

| Capacity | 500aEUR"20,000 tons/month (typical suitability) |

| Machine Weight | Approx. 2,500 kg |

| Test Speed | Up to 2 m/s (typical) |

| Test Width | 600 mm to 2,000 mm |

| Test Stroke | Continuous (dependent on coil/strip length) |

| Control Mode | Automatic / Manual |

| Delivery Time | 7-10 Days |

Company Details

Electronic & Engineering Company (I) P. Ltd. (EECI) is a leading ISO 9001:2008 accredited company, dedicated to provide innovative solutions in the field of Non Destructive Technology. EECI manufactures a broad range of NDT Products and Accessories, all of which adhere to International Standards. EECIÂÂÂÂA s products cater to various important industries such as the Steel, Aerospace, Railways, Defence, Oil & Gas, Nuclear, Heavy Engineering Industries and also, Renowned Educational Institutes. EECI has partnered with Internationally Acclaimed Manufacturers to provide Eddy Current Testing Systems, Magnetic Flux Leakage Testing Systems, Industrial Radiography Equipment, Rotary Ultrasonic Testing Systems, Scanning Acoustic Microscopes, Phased Array Equipment & Systems. Outside India, EECI has a diverse geographical client base, including markets such as USA, China, Middle East, Singapore, Korea, Mongolia, Africa, Malaysia, Bangladesh, Iran etc. EECI takes great pride in conceptualising, designing and perfecting all itÂÂÂÂA s products in a state-of-the-art Research & Development laboratory, recognised by Ministry of Science & Technology, Department of Science & Industrial Research, Govt. Of India With over 300 employees, vast experience and an advanced manufacturing facility, EECI has been able to achieve immense customer satisfaction.

Business Type

Exporter, Manufacturer, Supplier, Trading Company

Employee Count

500

Establishment

1995

Working Days

Monday To Saturday

GST NO

27AAACE3165H1ZS

Certification

ISO

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AAACE3165H1ZS

Mumbai, Maharashtra

Manager-sales

Mr Swaminand Singh

Members since

16 Years

Address

EEC House, C-7, Dalia Industrial Estate, Off New Link Road, Andheri (West), Mumbai, Maharashtra, 400053, India

Report incorrect details