Cnsl Based Resins

Price:

Get Latest Price

In Stock

Product Specifications

| Product Type | CNSL resin |

| Color | Dark Gray |

| Packaging | 25-50kg |

| Form | Powder/crystal |

| Mesh Size | 180-200 |

| Minimum Order | 500kg |

| Main Components | Cardol, Anacardic acid |

| Features | Water resistant, Chemical resistant, High adhesion, Durable coating, Cost effective, Versatile resin, Excellent film |

Product Overview

Key Features

Since the establishment of our company, we are engaged in meeting the varied needs of the customers by bringing forth highly appreciated CNSL Based Resins. These are manufactured by some of the experienced and quality focused professionals utilizing top-grade ingredients and modern techniques, which are sourced from reliable vendors. Owing to this, we are reckoned as a highly reliable manufacturer.

Note: In order to match the specifications of the esteemed customers, we provide CNSL Based Resins in different packaging options and at rates friendly to budget.

Additional Information:

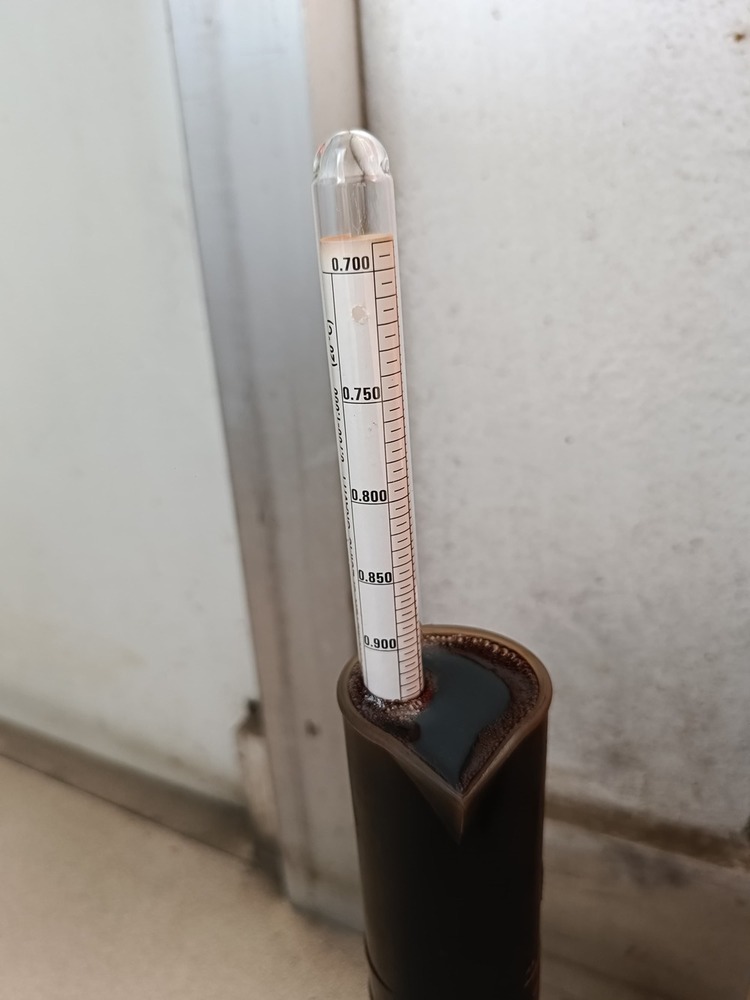

CNSL Based Resin primarily comprises two naturally produced Phenolic Compounds, which are Cardol and Anacardic Acid. Both of them are of non-drying category and only by chemical reaction they can be dried up. CNSL Resin has a golden color film and is a transparent viscous resin. It is best suitable for the applications of surface coating, where optimum water & chemical resistance along with excellent film properties are required. Therefore, CNSL Resin is utilized commonly as a paint raw material owing to its chemical resistant and high water property.

Compatibility- CNSL resin is suitable for all types of drying oil, epoxy, alkyd, phenolic, ester gum and malic acids in all proportions and only to a constricted magnitude with chlorinated resins, more for chlorinated rubber. They are not suitable for urea resin.

Applications of CNSL Based Resins:

Brake Lining:

CNSL Formaldehyde (NOVOLAC) resins are utilized for the preparation of brake liner binding

Paint and coatings:

- Applications of dark color enamels

- Excellent resistance to acid, water, alkali

Primers for metal and wood:

- Zinc chromate primer, Red oxide metal primer, other primers

- Provides Resistance against water, alkali, acid and related chemicals

Lacquer:

- Provides elasticity and toughness to the lacquer film

- Better performance than the ordinary oil paints in respect to grease moisture, resistance to oils and chemicals

Insulation Varnishes:

- To attain outstanding resistance and flexibility to other chemicals

- High adhesion and gloss properties

Laminating industry Resins:

Improves better bonding and age hardening to the substrate

Foundry core binders:

Enhances core collapsibility and improves anti-damp behavior and bench life in comparison to traditional core binders

Friction resistant material:

A remarkable heat resistant material and as a phenolic resin partial substitute to minimize cost

Rubber:

Enhances the tolerance of the product to wearing, action of acids & solvents and chemical attack

Polymer based cements:

For good adhesion and tolerance to moisture, alkalis and acids

Adhesives:

Advantage of price over traditional phenolic adhesives remrkable properties to match the incresing demand for durability and quality in bonding plywood

Minimum 500 kg order quantity

Packaging size 25 to 50 kg.

Available in powder and crystal form (180 to 200 mesh)

Company Details

Focusing on a customer-centric approach, ROCKWELL PLASTICS PVT. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Resin in bulk from ROCKWELL PLASTICS PVT. LTD. at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Employee Count

25

Establishment

1996

GST NO

06AAACR5948M1ZX

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 06AAACR5948M1ZX

Bahadurgarh, Haryana

Accepts only Domestic inquiries

Director

Mr. Dharamvir Singh

Address

Khasra No 18/1/2, Village Kassar, Sector 16, HSIIDC, Dist Bahadurgarh, Haryana, 124507, India

cashew nut shell oil in Bahadurgarh

Report incorrect details