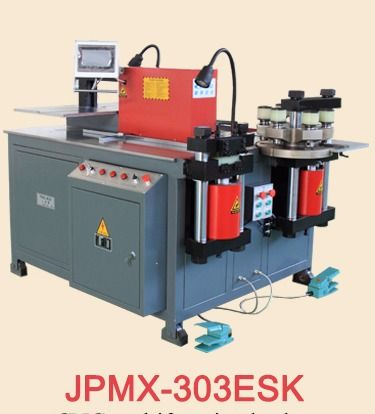

Cnc Noiseless Bus Bar Bending Punching Cutting Machine (Jpmx-303esk)

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | 1500X1000X1200 Mm |

| Power | 380V |

| Weight | 800Kg |

| Controller | Siemens Plc |

| Cutting Capacity | 30Mm |

| Punching Capacity | 25Mm |

| Features | Precise Bending, Quiet Operation, Multifunctional, High Precision, Easy Operation, Durable Design, Efficient Process, Flexible Setup |

Product Overview

Key Features

1.Product description of bus bar bending punching cutting machine:

#Working units:bending,punching,cutting work independently.

#Process metal:Copper/brass and aliminum busbars.

#Functions:1)cutting copper/aluminum busbar

2)punching round/oblong/arc/square hole

3)bending copper/aluminum busbar at vertical or horizontal direction.

4)special functions for twisting/embossing/cable pressing

#Main features:1)The cutting surface is flat,no burrs,no droop,no waste.

2)Rotarty six-mold turnplate can install six punching dies,no need to change the punching die.

3)Double working tables,three functions can work at the same time.

4)Siemens PLC Control system,high bending precision.

5)Machin can be moved to everywhere with four casters.

6)Machine has been installed well before delivery,easy to be operted by freshman.

2.Three working units of bus bar bending punching cutting machine:

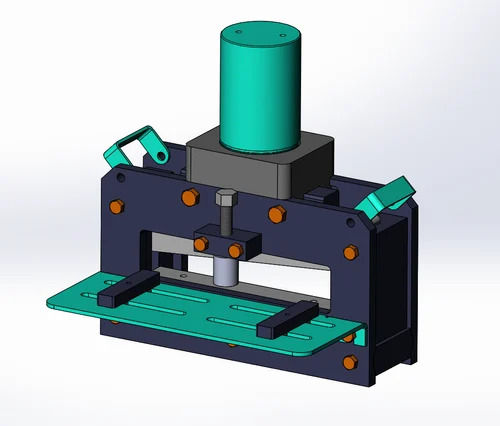

#Bending unit of bus bar bending punching cutting machine:

1)Siemens PLC Control System

2)only need to input thickness and angle on the touching screen,can get the busbar shape.

3)can finish L-bending,Z-bending,U-bending,embossing,twisting by exchanging different bending mold.

4)high bending precision A 1A ,repeat bending precision A 0.3A .

5)along with the machine,equiped with necessary bending mold,no need to buy additional spare parts.

6)bending dies can use for long-time.

#Punching unit of bus bar bending punching cutting machine:

1)Six-mold turnplate,install six punching dies at one time,no need to exchange punching dies frequently.

2)Six-mold turnplate to make sure the upper mold and the lower mold are absolutely in the center.

3)Punching location needle and locating ruler can help you to locate the busbar.

4)Can punch round,oblong,arc,square hole.

5)Can customise size of punching die according to your requirement.

#Cutting unit of bus bar bending punching cutting machine:

1)sharp shearing to make sure no burrs,no droops,no waste,cutting surface is flat.

2)cutting blade can exchange the direction to use,so 1 set of cutting blade can use for a long time.

3.Main components of bus bar bending punching cutting machine:

#AC contactor, thermal relay, circuit breaker (Schneider):

4.Company information of bus bar bending punching cutting machine:

We are professional manufacturer of busbar machine with experience for more than 10 years,we specialize in the developing,ptoducting,selling of leectrical ad CNC metalplate machines,we have many advanced management experience,strong technology and large selling networks.Our products rank the leading place in the industry.

Company Details

Jinan Jingpeng CNC Machinery Co., Ltd was founded in Jinan, China in 2008, and has been a prominent manufacturer, exporter of busbar processing machinery and metal processing machinery. Our main products include CNC multi-function busbar processing machine, non-cnc busbar processing machine, combined economical busbar machine, CNC busbar punching and shearing line, CNC busbar bending machine, CNC busbar chamfering machine, CNC sheet metal cutting machine. Our equipment are widely used in the industries of high and low voltage switch cabinet, switchgear, transformer, transformer station, electric switch, communication equipment, household appliances, shipbuilding and elevator manufacturing etc.

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

100

Establishment

2008

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Jinan, Shandong

Director

Ms. Kitty

Address

Office Add: A408, No.3, Fenghuangshan Road, Jinan, Shandong, 250000, China

busbar cutting machine in Jinan

Report incorrect details