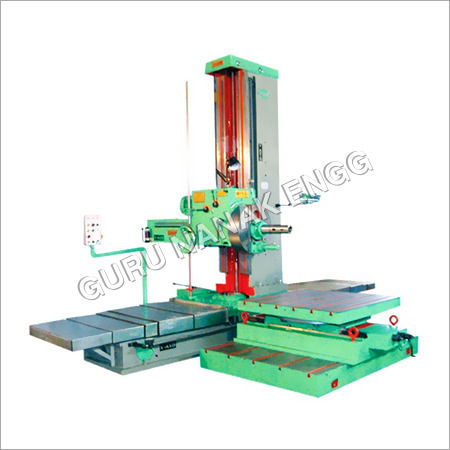

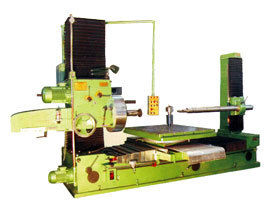

Cnc Horizontal Boring Milling Machine

Price:

Get Latest Price

In Stock

Product Specifications

| Spindle Diameter | 65-150 Mm |

| Morse Taper | 4-80 Metric |

| Longitudinal Movement | 410-800 Mm |

| Spindle Speeds | 9 |

| Spindle Speed Range | 15-300 Rpm |

| Spindle Feeds | 9 |

| Max. Spindle Height | 800-1500 Mm |

| Features | High Precision, Durable Design, Easy Operation, Low Maintenance, Energy Efficient, Versatile Use |

Product Overview

Key Features

Features:

-

Elevated Durability

-

Reliable operation

-

Less maintenance

-

Energy efficient

| Its technical specifications include

| AFTER We are instrumental in bringing a vast array of CNC Horizontal Boring Milling Machine that is used for various purpose like shaping solid material, drilling,key-way cutting, contouring, and die-sinking. This machine is fabricated using supreme grade components with the help of our skilled team of professionals as per the set industry norms. Moreover, this CNC Horizontal Boring Milling Machine is offered at market leading price to our clients at various specifications.

Features:

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

SPECIFICATIONS

|

|

MM

|

|

MM

|

|

MM

|

|

MM

|

|

MM

|

|

MM

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1. Alloy Steel Work Spindle Handened & Ground-Diameter

|

|

65

|

|

80

|

|

100

|

|

110

|

|

125

|

|

150

|

|

|

| |

|

2. Morse Taper Number

|

|

4

|

|

5

|

|

6

|

|

6

|

|

6

|

|

Metric 80

|

|

|

| |

|

3. Max. Longitudinal Movement of Working Spindle

|

|

410

|

|

510

|

|

510

|

|

510

|

|

600

|

|

800

|

|

|

| |

|

4. Number of Spindle Speeds

|

|

9

|

|

9

|

|

9

|

|

9

|

|

9

|

|

9

|

|

|

| |

|

5. Range of Spindle Speeds - R.P.M.

|

|

20 to 300

|

|

15 to 300

|

|

15 to 300

|

|

15 to 250

|

|

15 to 250

|

|

15 to 250

|

|

|

| |

|

6. Longitudinal Work Spindle Feeds (Nos.)

|

|

9

|

|

9

|

|

9

|

|

9

|

|

9

|

|

9

|

|

|

| |

|

7. Max. Height of the Spindle Axis

|

|

800

|

|

925

|

|

1000

|

|

1100

|

|

1250

|

|

1500

|

|

|

| |

|

8. Min. Height of the Spindle Axis

|

|

20

|

|

25

|

|

35

|

|

35

|

|

35

|

|

50

|

|

|

| |

|

9. Dimensions of the Rotary Table

|

|

880x1050

|

|

900x1125

|

|

1030x1375

|

|

1100x1450

|

|

1225x1675

|

|

1500x2000

|

|

|

| |

|

10. Longitudinal Table Traverse

|

|

1500

|

|

1625

|

|

1775

|

|

1925

|

|

2050

|

|

2225

|

|

|

| |

|

11. Long. Table Traverse Feeds

|

|

10

|

|

10

|

|

10

|

|

10

|

|

15

|

|

15

|

|

|

| |

|

12. Transversal Table Travel Feeds

|

|

10

|

|

10

|

|

10

|

|

10

|

|

15

|

|

15

|

|

|

| |

|

13. Vertical Head Stock Travel Feeds

|

|

4

|

|

4

|

|

4

|

|

4

|

|

15

|

|

15

|

|

|

| |

|

14. Rotary Table Autiomatic Feeds

|

|

10

|

|

10

|

|

10

|

|

10

|

|

15

|

|

15

|

|

|

| |

|

15. Max. Cross Movement of the Table

|

|

910

|

|

1000

|

|

1100

|

|

1300

|

|

1550

|

|

2000

|

|

|

| |

|

16. Max. Distance Between Stay Bearing

|

|

2150

|

|

2400

|

|

2690

|

|

2800

|

|

2950

|

|

3400

|

|

|

| |

|

17. Facing Head Diameter

|

|

450

|

|

505

|

|

555

|

|

600

|

|

650

|

|

700

|

|

|

| |

|

18. Weight Approximate in Kgs.

|

|

7500

|

|

8500

|

|

10000

|

|

11500

|

|

16500

|

20000

Company Details

Focusing on a customer-centric approach, GURU NANAK ENGG. WORKS (REGD.) has a pan-India presence and caters to a huge consumer base throughout the country. Buy Machineries in bulk from GURU NANAK ENGG. WORKS (REGD.) at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

25

Establishment

1955

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Batala, Punjab

Partner

Mr. Sharanjit Singh

Address

Kahnuwan Road, Simble Chowk, Batala, Punjab, 143505, India

cnc horizontal milling machine in Batala

Report incorrect details