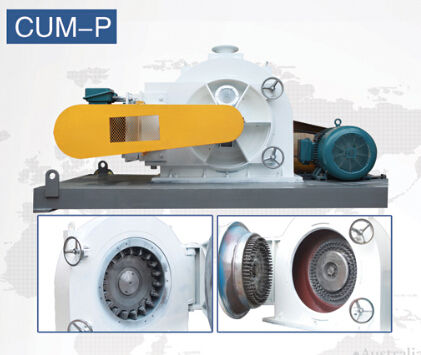

Classifier Mill Pulverizer Height: 8'.6"

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Stainless Steel |

| Dimensions | Vary By Model |

| Motor Power | 7.5-132 Kw |

| Capacity | 2-3000 Kg/H |

| Product Size | 2-75 Micron |

| Rotation Speed | 1700-7500 Rpm |

| Air Flow | 500-12000 M3/H |

| Features | Fine Powder Milling, Compact Design, High Efficiency, Adjustable Size, Wide Application, Low Power Use, Easy Operation, Durable System |

Product Overview

Key Features

- We manufacture Classifier Mill Pulverizer in sync with international standards.

- Thus, we are acclaimed as striking supplier, manufacturer and exporter.

Working Principle

Material would be conveyed by feeding system evenly to milling chamber, and would be impacted by high-speed rotating beater, and also under the centrifugal force, it would impact the grinding track. By several different pulverization powers, the material would be milled into fine powder. The milled powder would go with air flow up to the classifying chamber. With the help of adjustable classifier wheel, coarse powder and fine powder would be separated. Qualified fine powder would go through the wheel vane then into the cyclone separator or dust collector, while mixture of coarse powder and fine powder would fall down to the milling chamber to be milled again.

Advantages

- Milling and classifying in one system. Required product size achieved by the adjustment of classifier wheel.

- Compact structure, small space occupation, low installation power, wide application, and high performance cost.

- Different beater designs, pin shape, hammer shape and tooth shape, for different materials. High milling efficiency.

- Suitable for powder product milling between d50: 2micron and 75micron.

Parameters

| Type/Parameters | CSM-280H | CSM-400H | CSM-630H | CSM-800H | CSM-1000H | CSM-1250H |

|

| Motor (kw) | Grinding Disc | 7.5 | 18.5 | 30 | 45~55 | 75~90 | 132 |

|

| Classifier Wheel | 4 | 4 | 11~15 | 15 | 22 | 30 |

|

| Feeder | 0.55~1.1 |

|

|

|

|

|

| Rotation (r/min) | Grinding Disc | 7500 | 5250 | 3350 | 2625 | 2100 | 1700 |

|

| Classifier Wheel | 1000~8500 | 800~6000 | 600~4000 | 500~3000 | 400~2250 | 300~2000 |

|

| Feeder | 20~100 |

|

|

|

|

|

| Max. Air Flow (m3/h) | 500 | 1200 | 3000 | 4800 | 9000 | 12000 |

|

| Product Size(um) | 5~300 | 10~300 |

|

|

|

|

|

| Capacity (kg/h) | 2~120 | 15~600 | 25~1000 | 30~1500 | 60~2000 | 100~3000 |

|

Note: throughput depends on heavily raw material size, density, moisture and flow-ability. The data above is just for your reference.

Company Details

Focusing on a customer-centric approach, SHANDONG ALPA POWDER TECHNOLOGY CO. LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Grinding & Milling Machinery in bulk from SHANDONG ALPA POWDER TECHNOLOGY CO. LTD. at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

200

Establishment

2010

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Anqiu, Shandong

Mr Alpa Powder Tech India

Address

No.168, Wenhua Road, Advanced Manufacturing Industrial Park, Anqiu, Shandong, SD536, China

Report incorrect details