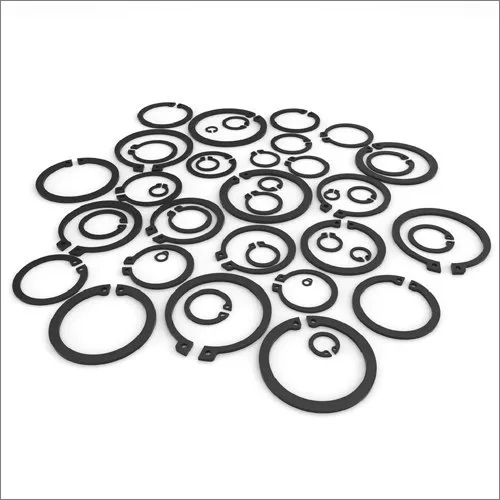

Circlips External - Stainless Steel (Ss316) & Mild Steel (Ms), Shaft Diameter 8-90mm | Dimensional Accuracy, Corrosion Resistance, Durable Finish

Price:

Get Latest Price

In Stock

Product Specifications

| Materials | Ss316 & Ms |

| Shaftdia | 8-90 |

| D3 Tol | +0.09 |

| D4Expanded | 15.2 |

| Axialforcekgf | 120-11900 |

| Features | Dimensional Accuracy, Corrosion Resistance, Sturdy Construction, Durable Finish |

Product Overview

Key Features

Our

abilities and mechanical expertise has enabled us to manufacture,

supply and export Circlips External. These products are made of

superior quality raw materials that are attained from the selected

sources of the market. Known for their effective functioning and

dimensional accuracy, these products have gained a high demand among

our clients in the global market. These products are applauded by the

clients for their ability withstand high pressure and weight.

Circlips External

is available with us in varied specifications in accordance to the

requirements of the clients.

Other details:

Clients can avail from us an extensive range of External Circlips which is designed in line with the International quality norms using finest quality raw materials such as EN-8, EN-42J, SS410, SS304, SS316 & MS that are sourced from reliable vendors of the industry. Known for their sturdy construction, dimensional accuracy, corrosion resistance and durable finish standards, these circlips are extensively demanded in different industry segments. Clients can buy these External Circlips from us in different technical specifications and at genuine market rates.

Specifications:

| Shaft Dia d1 | CIRCLIP | GROOVE DATA | |||||||||||

| S h11 | a Max | b Approx | D3 | Tol. On D3 | D4 Expan ded | d5 Min | d2 | Tol. On d2 | M1 H13 | M2 min | N min | Axial Force Kgf | |

| 8 | 0.8 | 3.2 | 1.5 | 7.4 | +0.09 | 15.2 | 1.2 | 7.6 | h11 | 0.9 | 1.0 | 0.6 | 120 |

| 9 | 1 | 3.3 | 1.7 | 8.4 | -0.18 | 16.4 | 8.6 | 1.1 | 1.2 | 138 | |||

| 10 | 1.8 | 9.3 | +0.15 -0.30 | 17.6 | 1.5 | 9.6 | 153 | ||||||

| 11 | 10.2 | +0.18 -0.36 | 18.6 | 10.5 | 0.75 | 210 | |||||||

| 12 | 11 | 19.6 | 1.7 | 11.5 | 230 | ||||||||

| 13 | 3.4 | 2 | 11.9 | 20.8 | 12.4 | 0.9 | 300 | ||||||

| 14 | 3.5 | 2.1 | 12.9 | 22.0 | 13.4 | 325 | |||||||

| 15 | 3.6 | 2.2 | 13.8 | 23.2 | 14.3 | 1.1 | 400 | ||||||

| 16 | 3.7 | 14.7 | 24.4 | 15.2 | 1.2 | 490 | |||||||

| 17 | 3.8 | 2.3 | 15.7 | 25.6 | 16.2 | 520 | |||||||

| 18 | 1.2 | 3.9 | 2.4 | 16.5 | 26.8 | 2.0 | 17.0 | 1.3 | 1.4 | 1.5 | 690 | ||

| 19 | 2.5 | 17.5 | 27.8 | 18.0 | h12 | 725 | |||||||

| 20 | 4.0 | 2.6 | 18.5 | +0.21 -0.42 | 29.0 | 19.0 | 770 | ||||||

| 21 | 4.1 | 2.7 | 19.5 | 30.2 | 20.0 | 805 | |||||||

| 22 | 4.2 | 2.8 | 20.5 | 31.4 | 21.0 | 845 | |||||||

| 24 | 4.4 | 3.0 | 22.2 | 33.8 | 22.9 | 1.7 | 1010 | ||||||

| 25 | 23.2 | 34.8 | 23.9 | 1060 | |||||||||

| 26 | 4.5 | 3.1 | 24.2 | 36.0 | 24.9 | 1100 | |||||||

| 28 | 1.5 | 4.7 | 3.2 | 25.9 | 38.4 | 26.6 | 2.1 | 1500 | |||||

| 29 | 4.8 | 3.4 | 26.9 | 39.6 | 27.6 | 1560 | |||||||

| 30 | 5.0 | 3.5 | 27.9 | 41.0 | 28.6 | 1.6 | 1.7 | 1620 | |||||

| 32 | 5.2 | 3.6 | 29.6 | 43.4 | 2.5 | 30.3 | 2.6 | 2100 | |||||

| 34 | 5.4 | 3.8 | 31.5 | +0.25 -0.50 | 45.8 | 32.3 | 2220 | ||||||

| 35 | 5.6 | 3.9 | 32.2 | 47.2 | 33.0 | 3.0 | 2670 | ||||||

| 36 | 1.75 | 4 | 33.2 | 48.2 | 34.0 | 1.85 | 2.0 | 2760 | |||||

| 38 | 5.8 | 4.2 | 35.2 | 50.6 | 36.0 | 2910 | |||||||

| 40 | 6.0 | 4.4 | 36.5 | +0.39 -0.78 | 53.0 | 37.5 | 3.8 | 3810 | |||||

| 42 | 6.5 | 4.5 | 38.5 | 56.0 | 39.5 | 4000 | |||||||

| 45 | 6.7 | 4.7 | 41.5 | 59.4 | 42.5 | 4300 | |||||||

| 48 | 6.9 | 5 | 44.5 | 62.8 | 45.5 | 4600 | |||||||

| 50 | 2.0 | 5.1 | 45.8 | 64.8 | 47.0 | 2.15 | 2.3 | 4.5 | 5700 | ||||

| 52 | 7.7 | 5.2 | 47.8 | 67.0 | 49.0 | 5950 | |||||||

| 55 | 7.2 | 5.4 | 50.8 | +0.46 -0.92 | 70.4 | 52.0 | 6300 | ||||||

| 56 | 7.3 | 5.5 | 51.8 | 71.6 | 53.0 | 6400 | |||||||

| 58 | 5.6 | 53.8 | 73.6 | 55.0 | 6650 | ||||||||

| 60 | 7.4 | 5.8 | 55.8 | 75.8 | 57.0 | 6900 | |||||||

| 62 | 7.5 | 6.0 | 57.8 | 78.0 | 59.0 | 6930 | |||||||

| 63 | 7.6 | 6.2 | 58.8 | 79.2 | 60.0 | 7020 | |||||||

| 65 | 2.5 | 7.8 | 6.3 | 60.8 | 81.6 | 3.0 | 62.2 | 2.65 | 2.8 | 5.3 | 7500 | ||

| 68 | 8.0 | 6.5 | 63.5 | 85.0 | 65.0 | 7840 | |||||||

| 70 | 8.1 | 6.6 | 65.5 | 87.2 | 67.0 | 8050 | |||||||

| 72 | 8.2 | 6.8 | 67.5 | 89.4 | 69.0 | 8300 | |||||||

| 75 | 8.4 | 7.0 | 70.5 | 92.8 | 72.0 | 8600 | |||||||

| 78 | 8.6 | 7.3 | 73.5 | 96.2 | 75.0 | 9000 | |||||||

| 80 | 7.4 | 74.5 | 98.2 | 76.5 | 10700 | ||||||||

| 82 | 8.7 | 7.6 | 76.5 | 101 | 78.5 | 11000 | |||||||

| 85 | 3.0 | 7.8 | 79.5 | +0.54 -1.08 | 104 | 3.5 | 81.5 | 3.15 | 3.3 | 11400 | |||

| 88 | 8.8 | 8.0 | 82.5 | 107 | 84.5 | 11900 | |||||||

| 90 | 8.2 | 84.5 | 109 | 86.5 | 12100 | ||||||||

| 95 | 9.4 | 8.6 | 89.5 | 115 | 91.5 | 12800 | |||||||

| 100 | 9.6 | 9 | 94.5 | 121 | 96.5 | 13500 | |||||||

| 105 | 4.0 | 9.9 | 9.3 | 98.0 | 126 | 101 | h13 | 4.15 | 4.3 | 6 | 16200 | ||

| 110 | 10.1 | 9.6 | 103.0 | 132 | 106 | 17000 | |||||||

| 115 | 10.6 | 9.8 | 108.0 | 138 | 111 | 17800 | |||||||

| 120 | 11.0 | 10.2 | 113.0 | 143 | 116 | 18500 | |||||||

| 125 | 11.4 | 10.4 | 118.0 | 149 | 4.0 | 121 | 19300 | ||||||

| 130 | 11.6 | 10.7 | 123.0 | +0.63 -1.26 | 155 | 126 | 20100 | ||||||

| 135 | 11.8 | 11 | 128.0 | 160 | 131 | 20900 | |||||||

| 140 | 12.0 | 11.2 | 133.0 | 165 | 136 | 21700 | |||||||

| 145 | 12.2 | 11.5 | 138.0 | 171 | 141 | 22500 | |||||||

| 150 | 13.0 | 11.8 | 142.0 | 177 | 145 | 7.5 | 28900 | ||||||

| 155 | 12.0 | 146.0 | 182 | 150 | 30000 | ||||||||

| 160 | 13.3 | 12.2 | 151.0 | 188 | 155 | 31000 | |||||||

| 165 | 13.5 | 12.5 | 155.5 | 193 | 160 | 32000 | |||||||

| 170 | 12.9 Max | 160.5 | 197 | 165 | 32900 | ||||||||

| 175 | 165.5 | 202 | 170 | 33800 | |||||||||

| 180 | 13.5 Max | 170.5 | 208 | 175 | 34500 | ||||||||

| 185 | 175.5 | 213 | 180 | 33800 | |||||||||

| 190 | 14.0 Max | 180.5 | +0.72 -1.44 | 219 | 185 | 33500 | |||||||

| 195 | 185.5 | 224 | 190 | 32700 | |||||||||

| 200 | 190.5 | 229 | 195 | 31900 | |||||||||

| 210 | 5.0 | 198 | 239 | 204 | 5.2 | 5.3 | 9.0 | 48800 | |||||

| 220 | 208 | 249 | 214 | 51200 | |||||||||

| 230 | 218 | 259 | 224 | 53500 | |||||||||

| 240 | 228 | 269 | 234 | 52900 | |||||||||

| 250 | 238 | 279 | 244 | 12.0 | 50300 | ||||||||

| 260 | 16.0 Max | 245 | 293 | 5.0 | 252 | 54400 | |||||||

| 270 | 255 | +0.81 -1.62 | 303 | 262 | 52500 | ||||||||

| 280 | 265 | 313 | 272 | 50800 | |||||||||

| 290 | 275 | 323 | 282 | 49100 | |||||||||

| 300 | 285 | 333 | 292 | 47300 | |||||||||

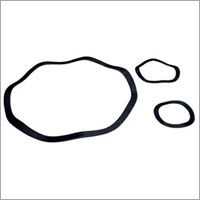

Internal Circlips

Introduction

Internal circlips are precision-engineered fasteners and are suitable for a wide variety of assemblies. They are designed to service as shoulders for accurately locating, retaining of locking components in bores. They are assembled in axial direction into pre-cut grooves, which assure precise locating of parts. They maintain constant pressure against the bottom of the groove and are secure against heavy thrust loads.

Salient Features

- As circlips are installed in pre-cut grooves, these pre-cut grooves can often be machined simultaneously with other costly machining operations.

- Speed of assembly and disassembly further reduces manufacturing costs.

- Space saving, compared to contemporary methods.

- Reduces assembly weight

- Longer service life.

Dimensions

For circlips of normal type, the dimensions, tolerances, and design data is given in Table1.

Material

All the Circlips are manufactured from spring steel of grade such as 70C6 or 75C6 confirming to IS: 2507- 1975 specification for cold rolled steel strips for springs (first revision)

Hardness

The hardness of the circlips are kept according to the following chart.

| Nominal Diameter of Circlips | Hardness | |

| Over | Up to | Hrc |

| - | 48 | 47 to 54 |

| 48 | 200 | 44 to 51 |

| 200 | 300 | 40 to 47 |

Finish

Unless the purchaser specifies any alternative finish, the circlip shall be chemically or thermally blackended.

Quality Assurance

All circlips are thoroughly inspected for parameters like circlips thickness, internal diameter, conical deformation, sprial flatness, hardness and function like set and grip.

| Bore Dia d1 | CIRCLIP | GROOVE DATA | |||||||||||

| S H11 | a Max | b Approx | D3 | Tol. On D3 | D4 Compr essed | d5 Min. | d2 | Tol. On d2 | M1 H13 | M2 min | N min | Axial Force Kgf | |

| 8 | 0.8 | 2.4 | 1.1 | 8.7 | +0.36 -0.18 | 2.8 | 1 | 8.4 | H11 | 128 | |||

| 9 | 2.5 | 1.3 | 9.8 | 3.5 | 9.4 | 0.9 | 1 | 0.6 | 144 | ||||

| 10 | 1 | 3.2 | 1.4 | 10.8 | 3.1 | 1.2 | 10.4 | 160 | |||||

| 11 | 3.3 | 1.5 | 11.8 | 3.9 | 11.4 | 176 | |||||||

| 12 | 3.4 | 1.7 | 13 | 4.7 | 1.5 | 12.5 | 0.75 | 240 | |||||

| 13 | 3.6 | 1.8 | 14.1 | 5.3 | 13.6 | 0.9 | 314 | ||||||

| 14 | 3.7 | 1.9 | 15.1 | 6 | 1.7 | 14.6 | 336 | ||||||

| 15 | 2 | 16.2 | 7 | 15.7 | 1.1 | 1.2 | 1.1 | 422 | |||||

| 16 | 3.8 | 17.3 | 7.7 | 16.8 | 1.2 | 515 | |||||||

| 17 | 3.9 | 2.1 | 18.3 | +0.42 -0.21 | 8.4 | 17.8 | 547 | ||||||

| 18 | 4.1 | 2.2 | 19.5 | 8.9 | 2 | 19. | 725 | ||||||

| 19 | 20.5 | 9.8 | 20 | H12 | 764 | ||||||||

| 20 | 4.2 | 2.3 | 21.5 | 10.6 | 21 | 1.5 | 780 | ||||||

| 21 | 2.4 | 22.5 | 11.6 | 22 | 810 | ||||||||

| 22 | 2.5 | 23.5 | 12.6 | 23 | 835 | ||||||||

| 24 | 1.2 | 4.4 | 2.6 | 25.9 | 14.2 | 25.2 | 1160 | ||||||

| 25 | 4.5 | 2.7 | 26.9 | 15 | 26.2 | 1.8 | 1200 | ||||||

| 26 | 4.7 | 2.8 | 27.9 | 15.6 | 27.2 | 1.3 | 1.4 | 1250 | |||||

| 28 | 4.8 | 2.9 | 30.1 | +0.50 -0.25 | 17.4 | 29.4 | 1.6 | 1.7 | 2.1 | 1330 | |||

| 30 | 4.8 | 3 | 32.1 | 19.4 | 31.4 | 1370 | |||||||

| 31 | 5.2 | 3.2 | 33.4 | 19.6 | 2.5 | 32.7 | 2.6 | 1380 | |||||

| 32 | 3.2 | 34.4 | 20.2 | 33.7 | 1390 | ||||||||

| 34 | 1.5 | 5.4 | 3.3 | 36.5 | 22.2 | 35.7 | 2320 | ||||||

| 35 | 3.4 | 37.8 | 23.2 | 37 | 3 | 2690 | |||||||

| 36 | 3.5 | 38.8 | 24.2 | 38 | 2640 | ||||||||

| 37 | 5.5 | 3.6 | 39.8 | 25 | 39 | 2716 | |||||||

| 38 | 3.7 | 40.8 | 26 | 40 | 2820 | ||||||||

| 40 | 1.75 | 5.8 | 3.9 | 43.5 | +0.78 -0.39 | 27.4 | 42.5 | 1.85 | 2 | 3.8 | 4050 | ||

| 42 | 5.9 | 4.1 | 45.5 | 29.2 | 44.5 | 4250 | |||||||

| 45 | 6.2 | 4.3 | 48.5 | 31.6 | 47.5 | 4310 | |||||||

| 47 | 6.4 | 4.4 | 50.5 | +0.92 -0.46 | 33.2 | 49.5 | 4350 | ||||||

| 48 | 4.5 | 51.5 | 34.6 | 50.5 | 4320 | ||||||||

| 51 | 2 | 6.5 | 4.6 | 54.2 | 36 | 53 | 2.15 | 2.3 | 6070 | ||||

| 52 | 6.7 | 4.7 | 56.2 | 37.6 | 55 | 6025 | |||||||

| 55 | 6.8 | 5 | 59.2 | 40.4 | 58 | 6350 | |||||||

| 56 | 5.1 | 60.2 | 41.4 | 59 | 6075 | ||||||||

| 58 | 6.9 | 5.2 | 62.2 | 43.2 | 61 | 6150 | |||||||

| 60 | 2 | 7.3 | 5.4 | 64.2 | 44.4 | 63 | H12 | 4.5 | 6210 | ||||

| 62 | 5.5 | 66.2 | 46.4 | 65 | 6170 | ||||||||

| 63 | 5.6 | 67.2 | 47.4 | 66 | 6160 | ||||||||

| 65 | 2.5 | 7.6 | 5.8 | 69.2 | 48.8 | 3 | 68 | 2.65 | 2.8 | 7820 | |||

| 68 | 7.8 | 6.1 | 72.5 | 51.4 | 71 | 8170 | |||||||

| 70 | 6.2 | 74.5 | 53.4 | 73 | 8420 | ||||||||

| 72 | 6.4 | 76.5 | 55.4 | 75 | 8650 | ||||||||

| 75 | 6.6 | 79.5 | 58.4 | 78 | 9000 | ||||||||

| 78 | 8.5 | 6.8 | 82.5 | +1.08 -0.54 | 60 | 3 | 81 | 9350 | |||||

| 80 | 7 | 85.5 | 62 | 83.5 | 5.3 | 11200 | |||||||

| 82 | 87.5 | 64 | 85.5 | 11500 | |||||||||

| 85 | 3 | 8.6 | 7.2 | 90.5 | 66.8 | 3.5 | 88.5 | 11900 | |||||

| 88 | 7.4 | 93.5 | 69.8 | 91.5 | 3.15 | 3.3 | 12300 | ||||||

| 90 | 7.6 | 95.5 | 71.8 | 93.5 | 12600 | ||||||||

| 92 | 8.7 | 7.8 | 97.5 | 73.6 | 195.5 | 12900 | |||||||

| 95 | 8.8 | 8.1 | 100.5 | 76.4 | 198.5 | 13300 | |||||||

| 98 | 9 | 8.3 | 103.5 | 79 | 101.5 | 13700 | |||||||

| 100 | 8.4 | 105.5 | 81 | 103.5 | 14000 | ||||||||

| 102 | 4 | 9.2 | 8.5 | 108 | 82.6 | 106 | H13 | 4.15 | 4.3 | 6 | 16300 | ||

| 105 | 8.7 | 112 | 85.6 | 109 | 16800 | ||||||||

| 108 | 9.5 | 8.9 | 115 | 88 | 112 | 17300 | |||||||

| 110 | 10.4 | 9 | 117 | 88.2 | 114 | 17600 | |||||||

| 112 | 10.5 | 9.1 | 119 | 90 | 116 | 17900 | |||||||

| 115 | 9.3 | 122 | +1.26 -0.63 | 93 | 119 | 18400 | |||||||

| 120 | 11 | 9.7 | 127 | 97 | 124 | 19200 | |||||||

| 125 | 10 | 132 | 102 | 4 | 129 | 19900 | |||||||

| 130 | 10.2 | 137 | 107 | 134 | 20700 | ||||||||

| 135 | 11.2 | 10.5 | 142 | 112 | 139 | 21500 | |||||||

| 140 | 10.7 | 147 | 117 | 144 | 22300 | ||||||||

| 145 | 11.4 | 10.9 | 152 | 122 | 149 | 23100 | |||||||

| 150 | 12 | 11.2 | 158 | 125 | 155 | 30000 | |||||||

| 155 | 11.4 | 164 | 130 | 160 | 30900 | ||||||||

| 160 | 11.6 | 169 | 133 | 165 | 31900 | ||||||||

| 170 | 12.2 | 179.5 | 145 | 175 | 7.5 | 33900 | |||||||

| 175 | 12.7 | 184.5 | +1.44 -0.72 | 149 | 180 | 34800 | |||||||

| 180 | 13.2 | 189.5 | 153 | 185 | 34500 | ||||||||

| 185 | 13.7 | 194.5 | 157 | 190 | 34930 | ||||||||

| 190 | 13.8 | 199.5 | 162 | 195 | 34000 | ||||||||

| 195 | 13.8 | 204.5 | 167 | 200 | 33000 | ||||||||

| 200 | 14 Max | 209.5 | 171 | 205 | 32500 | ||||||||

| 210 | 5 | 222 | 181 | 216 | 5.15 | 5.3 | 9 | 50000 | |||||

| 220 | 232 | 191 | 226 | 52200 | |||||||||

| 230 | 242 | 201 | 236 | 54900 | |||||||||

| 240 | 252 | +1.62 -0.81 | 211 | 246 | 52500 | ||||||||

| 250 | 262 | 221 | 256 | 50500 | |||||||||

| 260 | 16 Max | 275 | 227 | 5 | 268 | 12 | 54000 | ||||||

| 270 | 285 | 237 | 278 | 51800 | |||||||||

| 280 | 295 | 247 | 288 | 50000 | |||||||||

| 290 | 305 | 257 | 298 | 48200 | |||||||||

| 300 | 315 | 267 | 308 | 46500 | |||||||||

Company Details

Focusing on a customer-centric approach, COSMOS INDUSTRIAL CORPORATION has a pan-India presence and caters to a huge consumer base throughout the country. Buy Clips, Clamps in bulk from COSMOS INDUSTRIAL CORPORATION at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier, Wholesaler

Employee Count

20

Establishment

1963

Working Days

Monday To Sunday

GST NO

27AAEPV1786E1ZF

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AAEPV1786E1ZF

Mumbai, Maharashtra

Director

Mr. Nipun Vyas

Address

Office No-B-2/5, Hari Om Apartments, S.V. Road, Borivali West, Mumbai, Maharashtra, 400092, India

external circlips in Mumbai

Report incorrect details