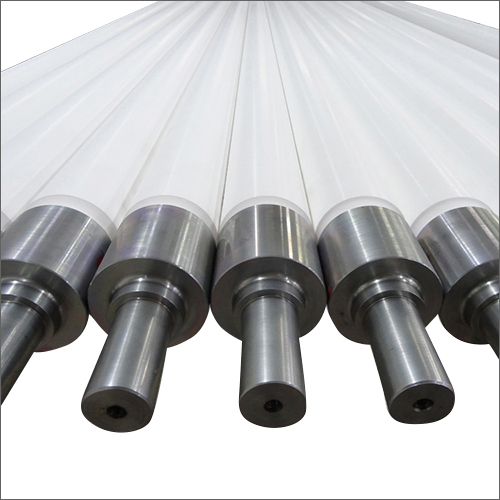

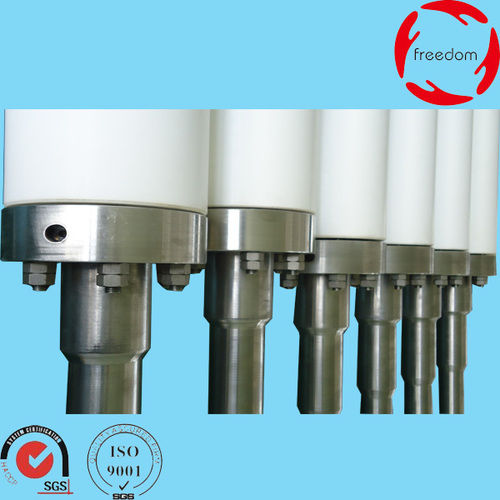

Ceramic Fused Silica Roller - Ir08502, Sio2 Material With 99.8% Purity, 1.95g/cm3 Density | High-temperature Resistance, Durable Surface, Low Thermal Expansion Coefficient

Price: 280 USD

Get Latest Price

Minimum Order Quantity :

5

In Stock

Product Specifications

| Technology | Vesuvius |

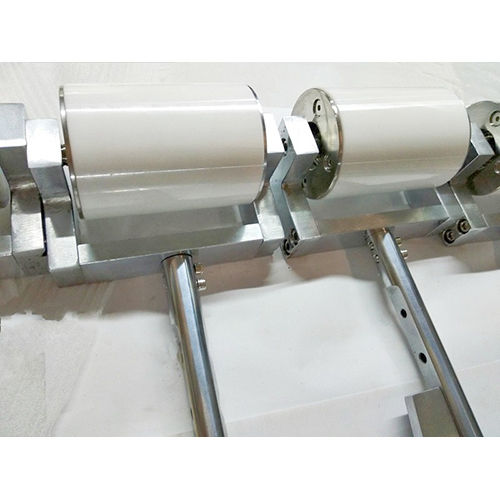

| Surface Treatment | Polishment |

| Type | Tempering and Processing |

| Material | Fused Silica |

| Function | Working and Processing |

| Application | Glass Processing And Tempering |

| FOB Port | SHANGHAI |

| Payment Terms | Cash Against Delivery (CAD), Cash on Delivery (COD), Letter of Credit (L/C), Western Union, Paypal, Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA) |

| Supply Ability | 50000 Per Year |

| Delivery Time | 5 Days |

| Sample Available | Yes |

| Sample Policy | Within a certain price range free samples are available |

| Packaging Details | Plywood cases Package |

| Main Export Market(s) | Eastern Europe, Central America, Africa, Middle East, South America, Western Europe, Australia, Asia, North America |

| Main Domestic Market | All India |

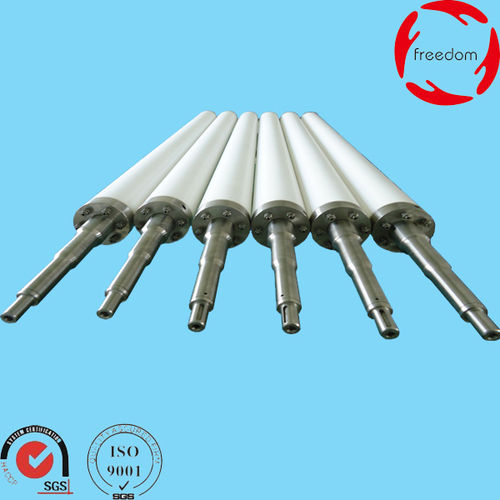

| Certifications | ISO 9001-20153C CertificateCE certificateSGS Certificate |

Product Overview

Key Features

Type:IR08502

material:SiO2i steel

purity:99.8%

density:1.95G/CM3

Bear strength:50MPA

Near temperture:1600 degree

Bear pressure:102MPA

Thermal coefficient:0.6*10-6

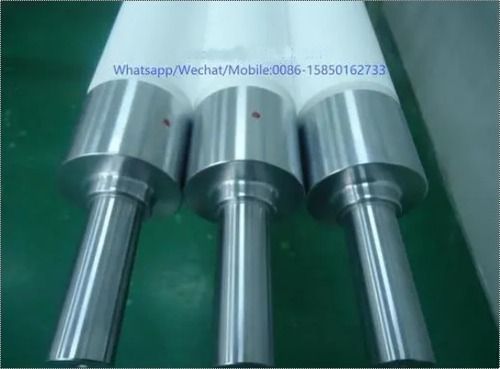

roughness:1.6UM

Radial beat:15um

Properties

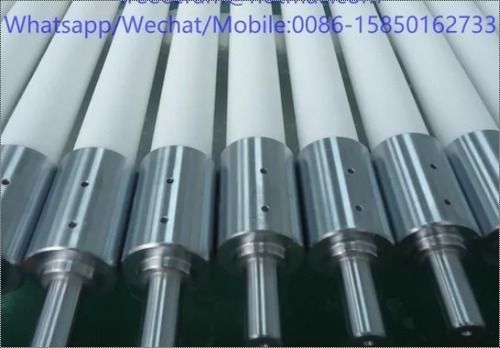

(1) With extremely low thermal-expansion coefficient, therefore it has the greatly strengthened thermostablility dose not distort under high temperature,, even in the oxidized atmosphere it may undergo the temperature fierce diversification within 1100A C environment

(2) With the fine inoxidizability, the product surface owns extremely durable properties.

(3) High-purity of chemical composition, thus refraining the ingredient of the product and the surface quality from pollution.

(4) The extremely ceramic physical properties guaranteed the stable performance under the ambient temperature and the operating temperature environment, with small size tolerance and outstanding, smooth surface quality, With the reliable axle neck, the serial number and quality examination report. our products own the traceability.

Details

Product Name : fused silica roller

Custom Code : 69039000

Category : Building Material Making Machinery

Parts Keywords : fused silica roller, ceramic roller, silica roller

Port : QINGDAO, SHANGHAI

Introduction

Choosing the fined high purity fused quartz as material, on the basis of introduction the foreign advanced molding and processing manufacturing cline, Our quartz ceramic roller may be used for as the key part component of the floating glass furnace. Which may bear and transit the glass.

Characteristic of fused quartz ceramic roller

* The extremely low thermal-expansion coefficient, the greatly strengthened heat shock stability, non-deformation with high temperature

* The high purity raw material, superior chemical physics performance

* The precise processing craft,precise size precision

* The reliable axle neck joint technology

Ceramic Advantage :

i Very low coefficient of thermal expansion (0.6x10-6/A C) thus it has high resistance to thermal shock.

i High chemical purity that does not pollute the glass and silicon liquid.

i Low thermal conductivity.

i High electrical insulation.

i Smooth surface for resistance to corrosion.

i High precision and big dimensional products are available.

Our Company Advantage :

1. We only supply fused silica ceramic roller since 12 years ago.

2. Tamglass, Glaston, North Glass, Land Glass, Mountain Glass...etc, OEM supplier

3. ISO 9001-2015

4. 2 years warranty for tempering furnace/plant

5. Toppest quality same as Vesuvius

6. Competitive price for each type of fused ceramic roller

7i Customized order for all dimension of fused ceramic roller

8. Customers prefer us for more than 39 countries

9. Maintain fused silica ceramic roller to help work longer lifetime

10. Glass flaws will be available to remove under our new roller with updated technology.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

165

Establishment

2007

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Suzhou, Jiangsu Sheng

Sales Director

Mr Whiney Wang

Address

Jinsigang Industrial Park, Guoxiang Street, Suzhou, Jiangsu Sheng, 215128, China

Report incorrect details