Cbctm Mortar Series - High Strength Sintered Alumina/silicon Carbide Compounds, Superior Wear Resistance & Temperature Versatility

Price:

Get Latest Price

Minimum Order Quantity :

1000

In Stock

Product Specifications

| Supply Ability | as per required Per Week |

| Delivery Time | 1 Week |

Product Overview

Key Features

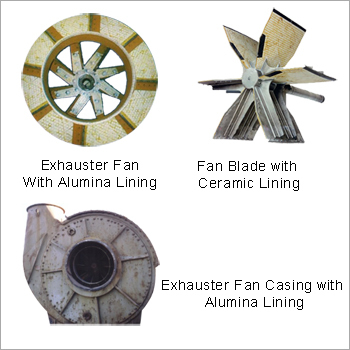

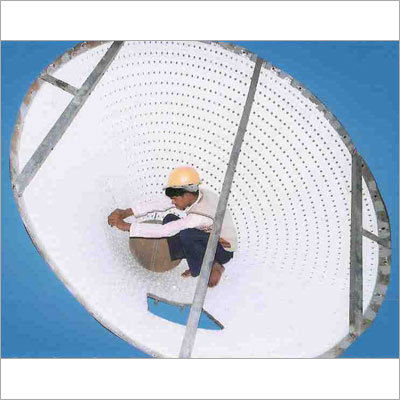

CBCTM is a mortar bonded product range; contains extremely hard sintered compounds like Alumina and Silicon Carbide as fillers in CBCTM Linings. CBCTM contains micro and nano-components to ensure high degree of densification by close the pores of the mortar element.

CBCTM is a range of extremely high strength compounds providing superior protection against moderate to severe wear conditions - available as both low and high temperature products, catering for process temperatures up to 1000C and 9000C respectively.

The high hardness fillers of sintered compounds incorporated in the CBCTM matrix offer extremely good sliding wear resistance. CBCTM has a hard sintered Alumina/Bauxite/Silicon Carbide base. CBCTM compounds are available with a variety of bonding agents, depending on the application.

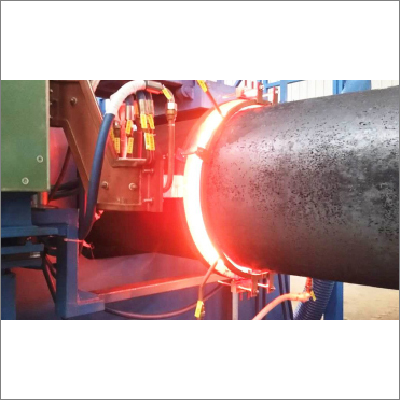

CBCTM has an advantage for all the grades about flexibility of use. CBCTM can be employed to install new linings with difficult profiles and on the roofs too using few simple lining tools. Recommended CBCTM lining thickness depends on the job requirements and application conditions. The thickness of the lining can be recommended after technical evaluation of BMW at the lining site. Curing time of CBCTM series of compounds is 48 hours.

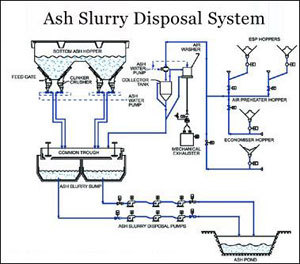

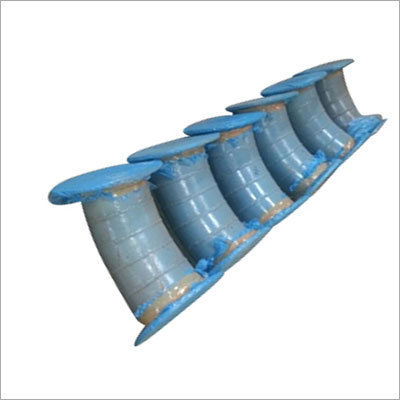

Application areas of plant equipment and system components lined with CBCTM:

- Drag Chin Conveyors;

- Pneumatic Conveying systems for Coal, Cement and Slag ;

- Dust Extraction Equipment; Hydro Cyclones, Cyclones;

- Grinding Mill internal lining for Classifier, mill body and difficult shapes.

- Static and Dynamic Separators; Chutes etc.

Standard Lining requirements:

- Install Mesh.

- Mix Dry Compound (consisting of mortar, metallic/poly fibre & Sintered Alumina granules/added with Silicon Carbide granules).

- Add water & BMW- S.Chem and mix.

- Trowel Mix onto Mesh.

- Spray BMW- cure on the CBC lining(after 10 hours of laying)

Company Details

Business Type

Exporter, Manufacturer, Supplier

Establishment

1961

Working Days

Monday To Sunday

GST NO

05AAACB7914R1ZB

Certification

An ISO 9001-2008 Certified Company

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 05AAACB7914R1ZB

Haridwar, Uttarakhand

Director

Mr Atul Lohia

Members since

16 Years

Address

Shiv Ganga Industrial Estate, Bhagwanpur, Haridwar, Uttarakhand, 247667, India

hardware fittings in Haridwar

Report incorrect details