Cast Basalt Interior Coating: Non-toxic And Eco-friendly 3-layer Non-stick Coating

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Cast basalt |

| Manufacturing process | Sintering |

| Temperature resistance | 300°C |

| Dimensions | Variable |

| Abrasion resistance | Excellent |

| Corrosion resistance | High |

| Friction coefficient | 0.021 |

| Features | High abrasion resistance, Excellent corrosion resistance, Low friction coefficient, Durable, Cost-effective, High quality, Easy installation |

Product Overview

Key Features

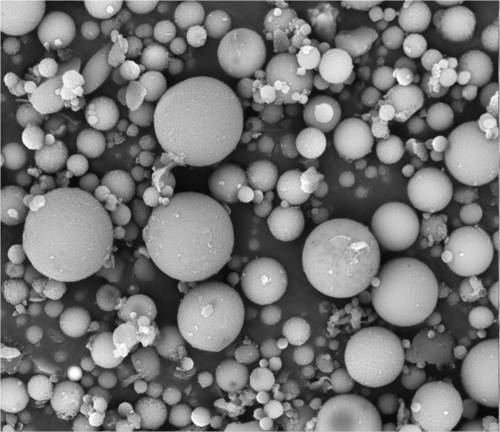

Cast Basalt Liners at BMW are manufactured by sintering the basalt

raw granules in the tunnel furnace at 1280oC. Advantage of this process

is that BMW can produce the desired composition of basalt liners to

produce best quality. Granules are shaped in metal moulds.

After crystallization the cast basalt liners are forwarded into cooling

zone of furnace, where they are passing through until they cool down

(8-10) hours. Then the cast basalt has high abrasion resistance,

corrosion resistance.

The cast basalt products are mainly used in the pneumatic pipe line to

convey sand, coal ash, fine slag slurry, tar sand slurry, lime, acid,

alkaline material. Cast Basalt Liners are also applied at the inclined

plane for cokes/coal chutes, ore cello, and lime and cement chutes,

cyclones, and separators where high abrasion resistance for lining

material is required.

Below table is for the tests conducted at 45 Deg angle Jet erosion

machine exposed for 15 minutes. Results exhibit excellent abrasion

resistance of cast basalt.

Test Material | Weight before test(g) | Weight after test(g) | Weight loss(g) |

BMW BASALT 450 | 43.0823 | 43.0769 | 0.0054 |

18% Cr STEEL | 65.8816 | 65.8653 | 0.0163 |

STAINLESS STEEL(AISI-310) | 67.8721 | 67.7855 | 0.0855 |

CARBON STEEL(IS-2063) | 61.5328 | 61.2629 | 0.27 |

Corrosion Resistance

It has good resistance against Acid, Alkaline and Acid medium. It is

advantageous in application areas where abrasion and Corrosion

resistance is needed. Low cost and High quality of cast basalt products

enable us to apply as anti-acid bricks below temp. 300oC. Anyhow Cast

Basalt is not resistant to hydrofluoric acid.

We can guarantee the corrosion resistance quality of BMW Cast Basalt

450 even when compared to FRP material used in anti-acid tank and pipe

line.

Sliding Characteristics

BMW Cast Basalt 450 lined pipes and chutes have been checked for the

coefficient of friction that is 0.021 it is smaller 20~30% than common

steel plate. Therefore the power consumed in transferring the ash or

other medium is much lower than the steel. In case of coal slide

channels wet coal do not need vibrator or manual pocking in order to

slide the coal on the surface.

Not only good sliding of Basalt 450 eases transfer of coal, but due to

reduced resistance improved discharging capacity. The more Basalt 450

is used, the better sliding is the surface.

Cast Basalt in Ash Pipeline and Bends

One of the major factor influencing bend wear rate is the conveying

velocity of the ash, density and the ash particle size. Lean-phase

system normally maintain velocity between 20-27 m/s. The metal bends

and pipes required to be replaced very frequently. To check the wear

bends are lined with Cast Basalt liners. In lower ID bends, wear

resistant Ni-Hard castings are also used. In this section we will

demonstrate our Cast Basalt lined bends.

Cast Basalt in Ash Sump Lining

The slurry from the bottom ash system as well as from fly ash system is

discharged by pipeline to the slurry pump through the ash sump. The

slurry sump is divided into compartments with common trough and plug

gate to feed respective sump. Due to the high density and velocity of

ash slurry in sump, erosion of surface is high. The power plants are

increasingly using Cast Basalt Liners as their preferred lining.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Establishment

1961

Working Days

Monday To Sunday

GST NO

05AAACB7914R1ZB

Certification

An ISO 9001-2008 Certified Company

Related Products

More Product From This seller

Seller Details

GST - 05AAACB7914R1ZB

Haridwar, Uttarakhand

Director

Mr Atul Lohia

Members since

16 Years

Address

Shiv Ganga Industrial Estate, Bhagwanpur, Haridwar, Uttarakhand, 247667, India

Ceramics in Haridwar

Report incorrect details