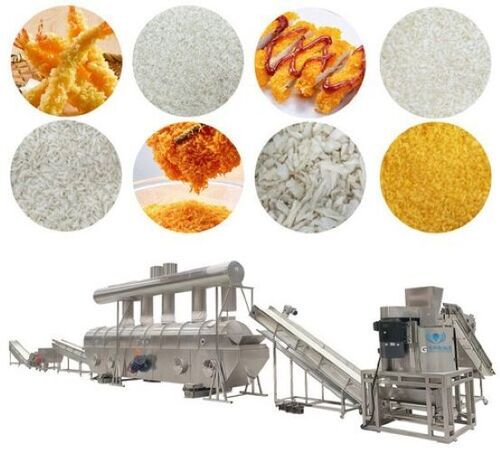

Bread Crumbs Production Line Machine - Color: Silver

Price: 9000 USD / Set

Get Latest Price

Minimum Order Quantity :

1 Set

In Stock

Product Specifications

| Product Type | Other, Bread Crumbs Production Line Machine |

| Material | Stainless Steel |

| Voltage | 400 Volt (v) |

| Color | Silver |

| Warranty | 1 Year |

| FOB Port | Qingdao,China |

| Payment Terms | Telegraphic Transfer (T/T) |

| Supply Ability | 30 Per Month |

| Delivery Time | 1 Months |

| Sample Available | Yes |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | Standand |

| Main Export Market(s) | Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East |

| Main Domestic Market | All India |

| Certifications | CE, ISO |

Product Overview

Key Features

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

100

Establishment

2000

Working Days

Monday To Sunday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Jinan, Shandong

General Manager

Mr. Grace Guo

Members since

1 Years

Address

No. 68, Jiuquzhuang Road, Shizhong District, Jinan, Shandong, 250000, China

bread making machine in Jinan

Report incorrect details