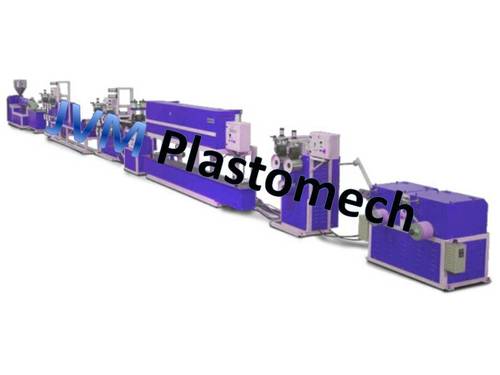

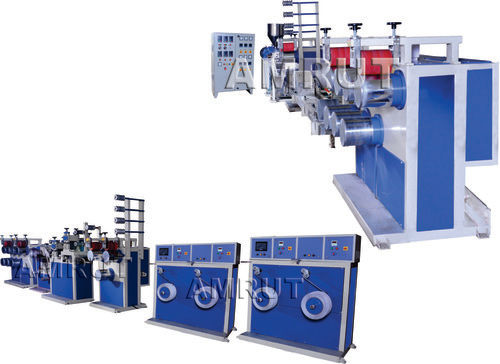

Pp Fully Automatic Box Strapping Plant - 130 Meter/min Speed, 6 To 19 Mm Strap Sizes, Nitrogen Treated Nitroy Alloy Steel Components, Stainless Steel Corrosion-resistant Quench Bath, Adjustable Embossing Depth And Temperature Control

Price:

Get Latest Price

In Stock

Product Specifications

| Max Speed | 130 M/Min |

| Strap Size | 6-19Mm |

| Screw Material | Nitrogen Treated |

| Gearbox | Helical |

| Temperature Control | Pid |

| Quench Bath | Stainless Steel |

| Take-Off Units | Heavy Duty |

| Features | High Speed, Durable, Precise Control, Easy Operation, Versatile, Efficient, Reliable, Cost-Effective |

Product Overview

Key Features

* Max. speed for each line : 130 Meter / min.

* Strap size : 6, 8, 9, 12, 15, 19 mm.

* Screw and Barrel are Nitrogen treated and stress relieved.

* Helical gear box with inbuilt thrust bearing are used for higher efficiency.

* PID Temperature controller provide accurate temperature control for proper melting in extruder.

* Quench bath is made from stainless steel to prevent corrosion & designed so air gap between die nozzle and water level is adjustable. * Two take OFF units are made from Heavy duty Structure and roller are Hard chrome for rust free performance. Pressure rollers are Operated Pneumatically or Manually.

* Two step heating in Orientation tank provides high scratching ratio and stability.

* Extremely convenient change for various widths of PP band.

* Embossing roller are made from nitroy alloy steel & heat treated for hardness and Embossing depth is adjustable.

Company Details

Focusing on a customer-centric approach, Gurunanak Engineering & Plastic Works has a pan-India presence and caters to a huge consumer base throughout the country. Get Packaging Machine from Gurunanak Engineering & Plastic Works at Trade India quality-assured services.

Business Type

Manufacturer, Service Provider, Supplier

Establishment

1998

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Vadodara, Gujarat

Proprietor

Mr. Surinder Pal Wadhan

Address

No. 908/1/5, Kiran Motor Lane, G. I. D. C. Makarpura, Vadodara, Gujarat, 390010, India

box strapping plant in Vadodara

Report incorrect details