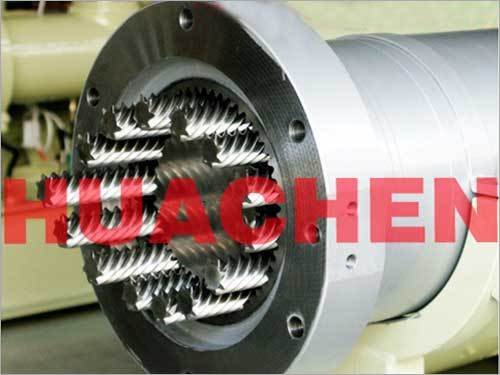

Blowing Machine Screw Barrel

Price:

Get Latest Price

In Stock

Product Specifications

| Base Material | 38CrMoAlA |

| Bimetallic Alloy | Fe-based alloy |

| Double-alloy level | Level A |

| Surface Treatment | Heat Treatment |

| Roughness | Ra0.4um |

| Linearity | 0.015mm |

| Hardness | HB240-280 |

| Features | Durable material, Corrosion resistant, Precise dimensions, Customizable solutions, Timely delivery, High quality, Stable dimension, Smooth finishing |

Product Overview

Key Features

Owing to our rich industrial experience and expertise, we have emerged as a major manufacturer of a wide assortment of Extruder Blowing Machine Screw Barrel For Film. Available at industry leading price, our range of screw barrel is manufactured keeping in mind all the prevailing quality standards of the industry. Our range of Extruder Blowing Machine Screw Barrel For Film is known for attributes such as quality-oriented, reliable, customized solution for all screw barrels, timely delivery and so on.

Features:

- Appreciated among our clients for its smooth finishing, dimensional stability and corrosion resistance

- Used in different machines such as CNC, extruder and injection & blow molding

- Quality approved materials and modern technique is used for making the barrel

- Offered in wooden box to protect it from scratch and damage during the transport

- Variety of dimensions and configurations available to suit clients' demand

Technical Parameter:

| Base Material | 1)38CrMoAlA(JIS SACM645);2)Cr12MOV(JIS SKD-11) ; 3)4Cr5MoSiV1(JIS SKD-61) ;4)42CrMo(AISI 4140) |

| Bimetallic Alloy Materials | 1)Fe-based alloy2)Ni-based alloy/Deloro alloy 3)Co-based alloy4)NiCo-based alloy 5)Tungsten carbide/Wolfram carbide |

| Double-alloy level | Level A - containing Tungsten of 40% Level B - containing tungsten of 25% Level C - containing tungsten of 15% |

| Surface Treatment | Heat Treatment High Frequency Treatment Nitriding treatment(120 Hours): Depth of Nitrided Layer: 0.5-0.8 mm Hardness of Nitrided Layer: 900-1020Hv (HRC56-65) Hard Chrome Plating treatment: Thickness of Hard Chrome Plating Layer: 0.05-0.10mm Hardness of Hard Chrome Plating Layer: 950HV Nickel alloy plating.treatment: Bimetallic Barrel/Cylinder: Centrifugal Casting (Inlay Alloy) Bimetallic Screw: Plasma Alloy Coating Spraying Depth of Bimetallic Layer: >2mm Hardness of Bimetallic Layer: HRC55-72 Spraying corrosion wear-resisting dual metal layers |

| Basic information | Roughness of the surface:Ra0.4um Linearity of the screw: 0.015mm Linear axis limit: 0.02mm Hardness after Hardening & Tempering: HB240-280 Fragility of Nitration:Two class |

| Material Applicaton | 1)General Plastics 2)ABS,PA,PC,PE,PET,PP,PS,EVA,PU,PVC,U-PVC,etc 3)PA + GF(Glass Fiber) 4)Flame-resistant Reinforced Plastics 5)Modified Engineering Plastics 6)All kinds of Mixed Recycled Material(in Scrap or Granule), PVC + 30% CaCo3, etc |

Why Us:

- Competitive pricing policy

- Skilled team of professionals and engineers

- Timely delivery of products at the clients

Packaging & Delivery

- Packaging Detail : Wooden box

- Delivery Detail : 10 To 15 days

Company Details

Focusing on a customer-centric approach, Zhejiang Huachen Screw Manufacturing Co., Ltd has a pan-India presence and caters to a huge consumer base throughout the country. Buy Screws in bulk from Zhejiang Huachen Screw Manufacturing Co., Ltd at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Establishment

1993

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Dinghai, Zhejiang

Ms. Rita Tang

Address

NO.1 Liuhang Road,Xihou Industrial Zone, Jintang Town, Dinghai, Zhejiang, 316031, China

machine screw in Dinghai

Report incorrect details

![Screw Barrel For Injection Molding Machine - 38CrMoAlA Alloy Steel, 10mm-300mm Diameter, Nitriding Treatment, [High Durability, Easy To Use, Precise Design, Excellent Quality, Wide Range]](https://tiimg.tistatic.com/fp/2/457/screw-barrel-for-injection-molding-machine-001.jpg)