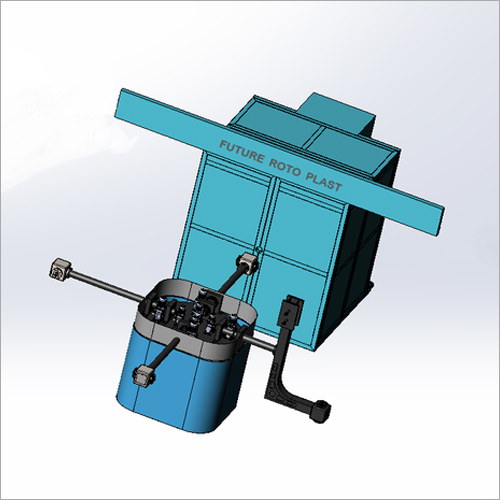

Bi-axial Machine - High-efficiency Insulated Oven With Ac Variable Speed Drives | Zero Defect Quality Assured, Energy Efficient Design, Controlled Indexing Motion

Price:

Get Latest Price

In Stock

Product Specifications

| Material | Steel |

| Dimensions | Variable |

| Power | Ac Variable Drives |

| Oven Material | Crca Sheet |

| Oven Insulation | 100Mm Thick |

| Control Panel | Powder Coated |

| Drive | Geared Motor |

| Features | Uniform Heating, Consistent Quality, Energy Efficient, Low Rejection Rate, Precise Control, Durable Design, Easy Operation, Versatile Use |

Product Overview

Key Features

A comprehensive range of Bi-Axials that we offer, is widely used in various industries for plastic process, in which heat is prime & crucial factor. Our range is 200% checked and tested by a team of quality controllers to ensure zero manufacturing defect. Moreover, our team of packaging experts packs all products using premium packing material to ensure safety during transportation.

The process of Bi-Axial is mentioned below

In the complete process, first the mold is loaded with the raw material in resin form. The loaded mold is then shifted in to Hot air oven where it is oriented and rotated at suitable low speed. As the molten resin gets properly heated & oriented, it adheres to the mold's inner surface until completely fused. Then the mold is moved to the air, water or the both to slowly reduce the temperature when the mold is still in rotating mode. Finally, the mold is is mantled to get the finished Roto molded article & is then again reloaded for the next cyclic process.

Salient features of our range are as follows::

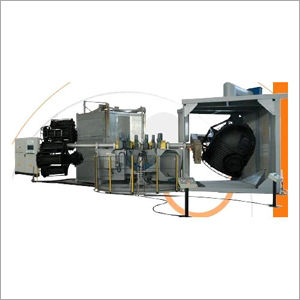

- Oven Chamber: Oven panel has been from Insulated from 1.5 mm thick CRCA sheet, sandwiched type 100 mm thick from caracole and wire mesh

- Oven doors operated electrically through geared motor and rack and pinion drive

- Oven forward and reverse movement is operated electrically from control panel through AC geared motor

- Arm locking system by sensor is provided

- Slip ring assembly is provided in the center of turret station

- Chamber is equipped with high velocity re - circulation blowers for fast heat transfer

- Hexagonal shaped chamber gives air guidance and economical energy consumption

- A heavy duty turret ID designed to carry out each of arms and housing of all six variable speed AC drives

- Turret station fabricated from heavy duty MS structure from square tube

- Most efficient in fuel & energy consumption compared to other types of machines

- Very consistent product quality due to smooth Bi-axial rotation

- Uniform heating of the mould with forced air circulation in heating chamber

- The base indexing motor provides controlled indexing of motion for arms without jerks

- Uniform distribution of material hence possible to produce tank with lesser weight

- Best compatibility in market due to lowest production cost per tank

- Lowest rejection rate due to sound & proven technology

- Flexibility to produce double & triple layer tanks due uniform distribution of material

- AC variable drives of reputed make for all minor & major axis's for minute & accurate speed control

- Powder coated electrical control panel with dust proof construction & with all switch gears of either imported or highly reliable

Company Details

Focusing on a customer-centric approach, ROTOPLUS ENGINEERS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Injection Moulding Machine in bulk from ROTOPLUS ENGINEERS at Trade India quality-assured products.

Business Type

Manufacturer, Supplier

Establishment

2005

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Ghaziabad, Uttar Pradesh

Proprietor

Mr. Yaseen Saifi

Address

Plot No- 27, Vikas nagar, Opposite Uttam Toyota Show Room, Ghaziabad, Uttar Pradesh, 201005, India

bi axial machine in Ghaziabad

Report incorrect details