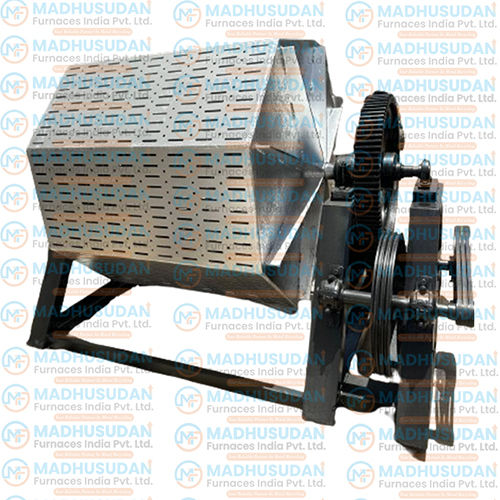

Ball Mill - Skeleton Pattern Design With Dual Hopper System, Enhanced Grinding Efficiency And Reliable Performance

Price:

Get Latest Price

In Stock

Product Specifications

| Type | Industrial Mill |

| Material | Steel |

| Capacity | Variable |

| Power | 100-500 kW |

| Dimensions | Customizable |

| Usage | Grinding ores and other materials, dry and wet |

| Standards | ISO 9001 |

| Features | Efficient grinding, Durable design, Wide usage, Reliable operation, Versatile applications, High capacity, Low maintenance |

Product Overview

Key Features

Ball Mill

Usage of Ball Mill:

Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and ball mill can be used for the dry and wet grinding for all kinds of ores and other grind-able materials.

Working principle of ball mill:

This ball mill is a skeleton pattern ball mill with horizontal cylindrical turning gear, drive by outer gear and two hoppers. The material goes to the first hopper after the spiraling by the quill shaft from the feeding equipment. The hopper has ladder sheathing or corrugated sheathing with steel balls inside, which will fall under the effect of centrifugal force by barrel turning to ram hard and grind material. After the kibbling in the first hopper, by monolayer partition panel, the material will enter the second hopper, which has plane scale board with steel ball inside to grind material. The powder material will be discharged from the grid plate to finish the grinding.

Structure of ball mill:

The ball mill is composed by feeding part, discharging part, turning part and driving part (reducer, small driving gear, electric motor and electric control). The quill shaft adopts cast steel part and the liner is detachable. The turning gearwheel adopts casting hobbing process and the drum is equipped with wear-resistant liner, which has good wear-resistance. The machine is with stable and reliable working condition. Moreover, according to different materials and discharging methods, there are dry ball mill and wet ball mill for choice

Company Details

Focusing on a customer-centric approach, DMECH ENGINEERS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Cement Plant Machinery in bulk from DMECH ENGINEERS at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier

Employee Count

10

Establishment

1985

GST NO

24ACTPP7828C1Z9

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24ACTPP7828C1Z9

Ahmedabad, Gujarat

Marketing Head

Mr. Vipul Panchal

Address

Plot No- B-118, Madhuram Estate, S.P. Ring Road, Near Kathwada G.I.D.C., Odhav, Ahmedabad, Gujarat, 382415, India

ball mill in Ahmedabad

Report incorrect details