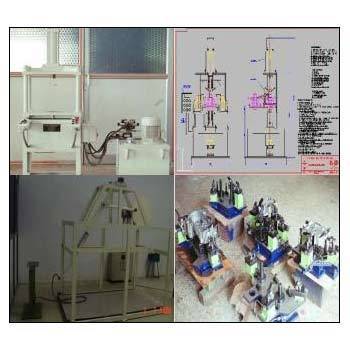

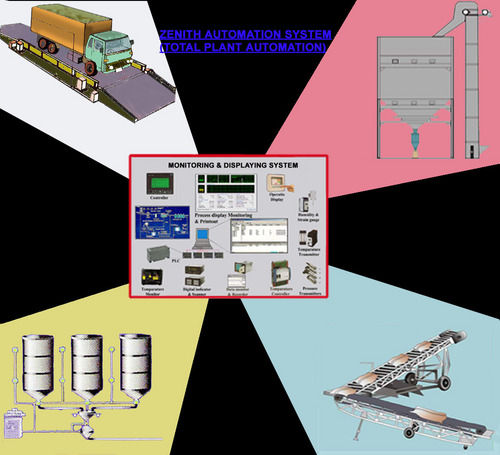

Automation System - Advanced Plc Integration For Bulk Plating Operations | Consistent Quality, Reduced Costs, Elimination Of Human Error, Enhanced Production Efficiency

Price:

Get Latest Price

In Stock

Product Specifications

| Product Type | PLC System |

| Dominant Color | Dark Gray |

| Power Supply | 24VDC |

| Input/Output | 128 I/O |

| Programming | Ladder Logic |

| Communication | Ethernet/Profibus |

| Dimensions | 400x300x150 mm |

| Weight | 20 kg |

| Usage | Bulk plating process automation; controls parameters like temperature, pH, current, and amperage hours. |

| Standards | IEC 61131-3 |

| Features | Improved Quality, Increased Production, Reduced Costs, Error Elimination, Regulated Inputs, Efficient Control |

Product Overview

Key Features

- Consistency and improvement in quality.

- Increased production under optimum conditions.

- Reduction in production bottlenecks.

- Reduction in chemical costs.

- Reduction in labour and operational costs.

- Elimination of human error.

- Regulated inputs.

- Reduction in inspection.

- Maintenance of operating efficiency.

- Effective control of production.

- Versatility and

- Quality consciousness

With the advent of computers and industrial logic controllers, the material handling systems of plating plants have become far more flexible with unending possibilities, limited only by commercial prudence. Important parameters like raw materials control, data logging of production and other MIS systems can be incorporated. The PLC which is the most vital part of automation itself can be interfaced with a main computer to integrate with the automatic production line.

PLCs can also be provided with necessary auxiliary driver cards with I/O's (analog / digital) wherever required and software packages for controlling parameters like process temperature, pH, plating current, ampere hr., consumption, etc.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

900

Establishment

1957

Working Days

Monday To Saturday

GST NO

27AAACG3741K2ZK

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AAACG3741K2ZK

Mumbai, Maharashtra

Senior Executive

Mr Vijay George

Members since

5 Years

Address

Growel Corporate, Akurli Road, Kandivali East, Mumbai, Maharashtra, 400101, India

automation software in Mumbai

Report incorrect details