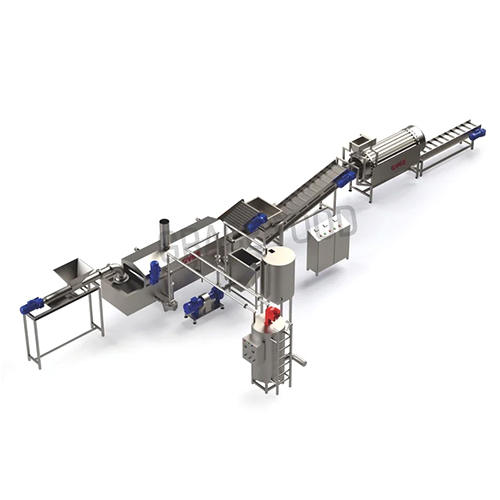

Energy Effiecient Automatic Wafer Stick Making Machine

Price:

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Product Type | Biscuit |

| General Use | Wafer Making |

| Material | Stainless Steel |

| Texture | Other |

| Type | Snacks Extruder |

| Product Shape | Stick |

| Fat Content (%) | 1 Percentage ( % ) |

| Automatic | Yes |

| Packaging | Single Package |

| Installation Type | Free Stand |

| Feature | ECO Friendly, Lower Energy Consumption, High Efficiency |

| Color | Other, Grey |

| FOB Port | shanghai port |

| Payment Terms | Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Letter of Credit (L/C) |

| Supply Ability | 10 Per Day |

| Delivery Time | 10 Days |

| Sample Policy | Contact us for information regarding our sample policy |

| Main Export Market(s) | Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa |

Product Overview

Key Features

Here's a general introduction to how the machine works:

1. Wafer roll Ingredients Mixing: The initial phase of the process involves mixing the ingredients to make the wafer batter. This typically involves flour, sugar, eggs, oil, and other components. The mixture is made in a large vat and must be consistent in texture and composition.

2. Wafer roll Baking: Once the batter is ready, it's transferred into the baking system of the machine. The machine has specially designed plates that heat the batter, causing it to harden and take on the distinctive shape of wafer sticks. This process involves high temperatures and precise timing to ensure the wafer sticks are perfectly cooked.

3. Egg Rolling and Cutting: After baking, the flat, cooked batter is then rolled into the stick form while it's still hot and pliable. Some machines do this mechanically with the use of rollers, while others use air pressure. Once rolled, the wafer sticks are then cut into the desired lengths.

4. Wafer roll machine Cooling system : The newly formed and cut wafer sticks then need to be cooled. This can be done in open air or in a controlled cooling system, depending on the specific design of the machine.

5. Wafer roll Filling (optional): Some wafer sticks have a cream filling. If this is the case, an additional machine or module may be used to inject the filling into the cooled wafer sticks.

6. Wafer roll Packaging: Finally, the wafer sticks are packaged. This can involve wrapping individual sticks or placing a certain number into a bag or box. Packaging can be done manually, although larger operations often use automated packaging machines.

The design and specifics of automatic wafer stick machines can vary greatly depending on the manufacturer, the scale of production, and other factors. The automation level can also vary, with some machines being almost entirely automatic, while others may require human supervision or intervention at certain stages. Regardless, the aim is to produce a consistent, high-quality product in the most efficient manner possible.

Company Details

Focusing on a customer-centric approach, Shanghai Zhenghua Confectionery Machine Co; Ltd has a pan-India presence and caters to a huge consumer base throughout the country. Buy Food Processing Machinery in bulk from Shanghai Zhenghua Confectionery Machine Co; Ltd at Trade India quality-assured products.

Business Type

Manufacturer

Employee Count

100

Establishment

1999

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Shanghai, Shanghai

Mr. Awa

Address

Nanqiao Town, Fengxian District, Shanghai Shanghai, Shanghai, 201400, China

wafer making machine in Shanghai

Report incorrect details