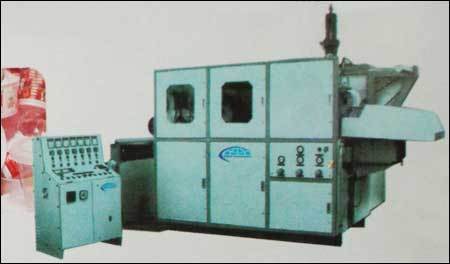

Automatic Thermoforming Machines - Tested Quality Steel & Aluminum, 50 Ml To 300 Ml Capacity | Infrared Ceramic Heaters, High-speed Production At 1800 Cycles/hour

Price:

Get Latest Price

In Stock

Product Specifications

| Materials | Steel & Aluminum |

| Dimensions | Variable |

| Power | Variable |

| Capacity | 50-300Ml |

| Speed | 1800 Cycles/Hour |

| Heaters | Infrared Ceramic |

| Control | Plc Based |

| Features | High Speed, Precise Feeding, Durable Design, Automatic Ejection, Easy Operation, Versatile Use, Cost Effective, High Output, Reliable System |

Product Overview

Key Features

Automatic

Thermoforming Machines

Owing to our wide

industrial experience in the domain and the in depth technical knowledge of our

team, we are engaged in offering Automatic

Thermoforming Machines. These machines are developed by us using tested quality

steels & aluminum that is sourced from reckoned vendors of the market. Accredited

for their corrosion resistance surface, fine finish and impeccable performance,

Automatic Thermoforming Machinesare used in the construction of disposable containers using

materials such as PVC, HIPS, LDPE and PET.

Further Details:

Automatic Thermoforming Machines developed by our organization specially cater to form Disposable containers from 50 ml to 300 ml. Wide range of thermoplastic viz. HIPS, PVC, PET, PP can be formed into tumblers, drinking glass, any deepdrawn containers. Infrared ceramic heaters are used for pressure forming. Average speed of production is 1800 cycles/hour. Some features that makeAutomatic Thermoforming Machines a global demand are following.

Features

- Hi-tech self loading reel holder to load heavy large diameter reels.

- The film in-feed is through the proven and tested high strength chain system which ensures high speed and precision feeding.

- The film is heated either on one side or both depending on type of film & production requirement through true infrared ceramic heaters .

- The forming station comprises of highly smooth and heavy duty mobile platens operated by air cylinders. The fine quality thin walled disposables are formed by automatic forming. The cooling is accomplished by chilled water generated by chiller of appropriate capacity.

- A jet of air automatically starts operation of ejection of the thin walled containers.

- An external control panel along with all necessary controls installed is provided for the setting up of the machine. After initial setup manually, the dedicated motor comes into operation. The sequential operation starts through chain and sprocket drive. The cam controlled system, limit switches comes into operation after suitable setting up of the timers. The electrical control system is for fail safe operation. Emergency stop switches are also provided for added safety.

Company Details

Focusing on a customer-centric approach, GLOBAL THERMOFORMERS has a pan-India presence and caters to a huge consumer base throughout the country. Buy Plastic Processing Machinery in bulk from GLOBAL THERMOFORMERS at Trade India quality-assured products.

Business Type

Exporter, Importer, Manufacturer, Supplier

Employee Count

20

Establishment

2005

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Faridabad, Haryana

Director

Mr. Gopal Sharma

Address

Plot No. 127, S.M.I.E, Near Mujesar Railway Crossing, 20/2, Mathura Road, Faridabad, Haryana, 121006, India

Report incorrect details