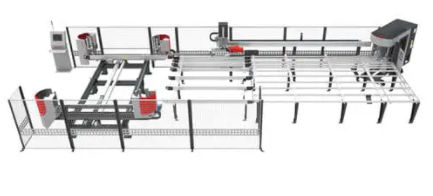

Automatic Orbital Welding Machine - Carbon Fiber & Aviation Aluminum, 200x200x50mm, 1a Output Current | Multi-function Remote Control, Water Cooling, All-position Capability

Price Trend: 79000.00 - 317000.00 USD

Get Latest Price

Minimum Order Quantity :

1

In Stock

Product Specifications

| Efficiency | 30min |

| Usage | Automatic orbital welding machine |

| Pulse Frequency | 60 Hertz (HZ) |

| Motor Type | Electric motor |

| Cooling Method | Water cooling |

| Condition | New |

| Welding Area | 60 Square Inch (in2) |

| Dimension (L*W*H) | 200x200X50 Millimeter (mm) |

| Insulation Grade | Class II |

| Output Current | 1 Ampere (amp) |

| Input Current | 10 |

| Power | 10 Ampere (amp) |

| Frequency | 60 Hertz (HZ) |

| Function | Automatic orbital welding machine (GMAW / FMAW / MIG / TIG) |

| Rod Diameter | 0.6 |

| Arc Current | 1 Ampere (amp) |

| Voltage | 1 Watt (w) |

| Type | Automatic orbital welding machine |

| Weight | 15 Kilograms (kg) |

| FOB Port | Qingdao/Tianjin/Shanghai |

| Supply Ability | 50 Per Month |

| Delivery Time | 60 Days |

| Sample Available | No |

| Sample Policy | Sample costs shipping and taxes has to be paid by the buyer |

| Packaging Details | Sea plywood case |

| Main Domestic Market | All India |

| Certifications | CE |

Product Overview

Key Features

Technical points and advantages of DP automatic orbital Welding Machine:

1.Applicable pipe size for 4 in and above

2.Welding bug material use carbon fiber and aviation aluminum which makes weight is lightest

3. Configuration of all-position automatic orbital welding machine:

1pc of controller

1 pc gas mixture ratio device

1 pc of welding bug with dual torch

2 pcs of Miller450 welding power source

2 pcs of Miller wire feeder

1pc of Miller high-capacity water tank

Also all-position automatic orbital welding machine equipped with multi function remote controller and operator-machine interface for use

One welding station compose of 2 sets of all-position automatic orbital welding machine

4.Multi function remote controller designed by ourselves, it is also available in extreme weather.

5. Automatic tracing system including axial and radial direction is equipped in the automatic orbital welding machine.

6. All-position automatic orbital welding machine is workable under two welding

procedures:

A: Internal welding machine for root pass, automatic external pipe welding machine for hot pass, filling pass and capping pass

B: Automatic external pipe welding machine associated with internal line up clamp with

copper shoes for root pass, other passes are be doing by automatic external pipe welding machine as well.

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

60

Establishment

2005

Working Days

Monday To Saturday

Payment Mode

Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Luoyang, Henan

Foreign Trading Manager

Mr Michelle Wan

Address

Intersection of Heluo Road and Sanyuan Road, Hi-tech Development Zone, Luoyang, Henan, 471003, China

automatic welding machine in Luoyang

Report incorrect details