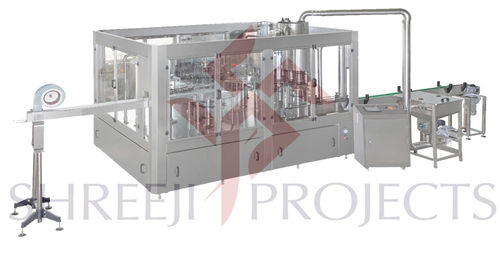

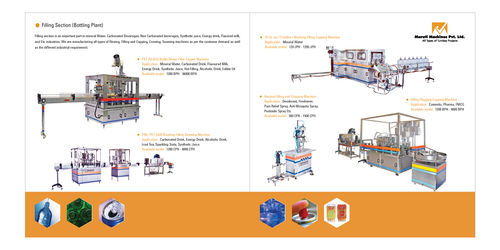

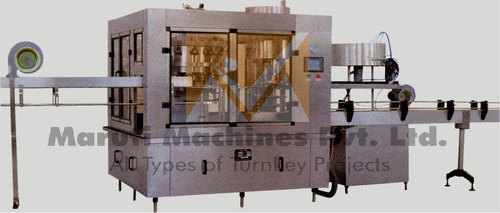

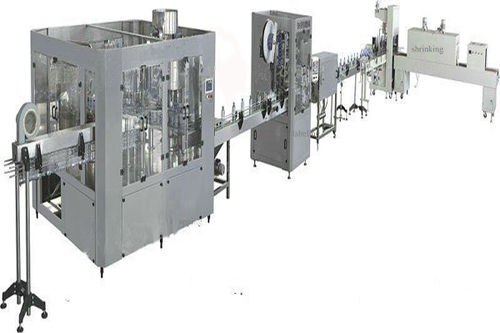

Automatic Juice Production Line - Capacity: As Per The Client Required Kg/hr

Price:

Get Latest Price

Minimum Order Quantity :

1

Brand Name :

Shree Bhagwati

In Stock

Product Specifications

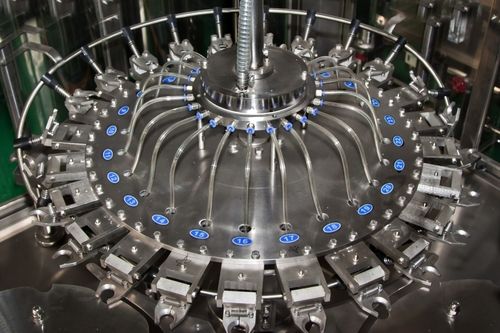

| Type | Packaging Line |

| Material | Stainless Steel |

| Auxiliary Packaging Machine Type | Other |

| Capacity | As per the client required Kg/hr |

| Computerized | Yes |

| Automatic Grade | Automatic |

| Control System | PLC Control |

| Drive Type | Electric |

| Power | As per the client required Volt (v) |

| Voltage | As per the client required Volt (v) |

| Weight (kg) | 15000 kg Kilograms (kg) |

| Dimension (L*W*H) | In Inches Inch (in) |

| Color | Other |

| Warranty | 1 Year |

| FOB Port | India |

| Payment Terms | Letter of Credit (L/C), Telegraphic Transfer (T/T), Letter of Credit at Sight (Sight L/C), Cash in Advance (CID), Cheque, Cash Advance (CA) |

| Supply Ability | 10 Per Week |

| Delivery Time | 4-6 Week |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | Wooden Packing only |

| Main Export Market(s) | Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Central America, Asia |

| Main Domestic Market | All India |

| Certifications | ISO and CE Certified |

Product Overview

Key Features

Company Details

Shree Bhagwati Group of Companies is World leader in the design and manufacture of automatic instruments for the processing machinery and packaging machinery for various industries like dairy, pesticides, distilleries, Breweries, Lube packaging, Cosmetics & Toiletires, edible oil industry, food and ancillaries etc. of international standard at reasonable prices. A wide range of high quality pharma equipments and packaging equipments with enhanced technology are available with us. Our pharmaceutical machineries include filling machines for liquid and powder, washing machine, various types of labeling equipments like sticker labelling, Self adhesive labeler, instruments for tablet, capping, ointment, bottle inspection instruments, turn table, blister packing and tablet press, liquid manufacturing plants, Vibro sifters, storage vessels, lab scale machine, packing conveyors used in pharmaceutical and other industries. We are a leading engineering company, with a reputation for designing, manufacturing, installing and commissioning fabricated stainless steel process and packaging equipments. We have earned the trust of many companies over the past 2 decades and currently serve them through 2 manufacturing facilities in India with a combined work area exceeding 70,000 sq. ft. We always try to exceed customer expectations through our efficient leadership, engineering excellence, cutting technology and professional approach. By upgrading our pharmaceutical machinery as per the latest technology, we have always been successful in meeting the challenges arising out of the requirements set by the pharmaceutical industries. Our range of pharmaceutical machines have been exported to USA, France, Poland, Bulgaria, Saudi Arabia, Ecuador, Peru, South Africa, Egypt, Indonesia, UAE, Vietnam, Pakistan, Uganda, Philippines, Greece, Columbia, Malaysia, Nigeria, Ethiopia, Lebanon, Kenya, Kuwait, Sri Lanka, Ghana, Nepal, Ukraine, Bangladesh, Australia, Switzerland, Russia, Yemen, Iran, Morocco, Malawi, Thailand, Tanzania, Canada, Belarus and many more.

Business Type

Exporter, Manufacturer, Distributor, Supplier

Employee Count

30

Establishment

1999

Working Days

Monday To Saturday

GST NO

24AANCS9768F1ZQ

Payment Mode

Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID), Cheque, Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

Certification

ISO 9001 : 2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AANCS9768F1ZQ

Ahmedabad, Gujarat

Ceo

Mr Arjun Rao

Members since

8 Years

Address

Plot No. 2802, ROAD NO - 4 E, Near Ramol Char Rasta, Phase-IV, GIDC, Vatva, Ahmedabad, Gujarat, 382445, India

synthetic juice plant in Ahmedabad

Report incorrect details