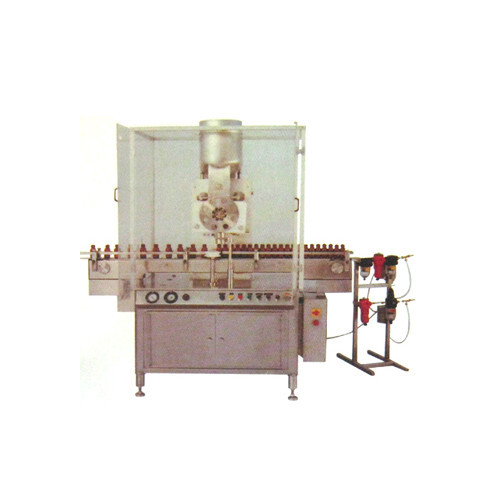

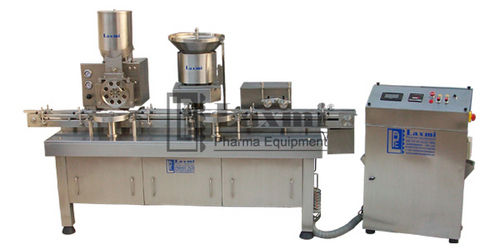

Automatic High Speed Injectable Powder Filling & Stoppering (Full & Half Bunging) Machine

Price:

Get Latest Price

In Stock

Product Specifications

| Filling Heads | 8 |

| Output | 120 VPM |

| Power | 440V, 3 Phase |

| Net Weight | 825 kgs |

| Dimensions | 2500x900x1700 mm |

| Materials | SS304, SS316 |

| Accuracy | 1% |

| Features | High speed, Accurate filling, Easy operation, Compact design, Automatic system, GMP compliant, Low wastage, Versatile machine |

Product Overview

Key Features

Automatic High Speed Injectable Powder Filling & Stoppering (Full & Half bunging) Machine

LAXMI | ||||||||||||||||||||||||||||||||||||||||

| Silent Feature : | ||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||

| Application : | ||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||

Company Details

Focusing on a customer-centric approach, LAXMI PHARMA EQUIPMENT has a pan-India presence and caters to a huge consumer base throughout the country. Buy Pharmaceutical Machinery in bulk from LAXMI PHARMA EQUIPMENT at Trade India quality-assured products.

Business Type

Exporter, Manufacturer, Supplier, Wholesaler

Employee Count

25

Establishment

1985

Working Days

Monday To Saturday

GST NO

24AABFL4855F1ZH

Payment Mode

Cheque

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 24AABFL4855F1ZH

Ahmedabad, Gujarat

Sr.marketing Executive

Mr Pujan Pandya

Members since

5 Years

Address

Plot No. 1314, G.I.D.C, Industrial Area, Phase- III, Vatva, Ahmedabad, Gujarat, 382445, India

Report incorrect details