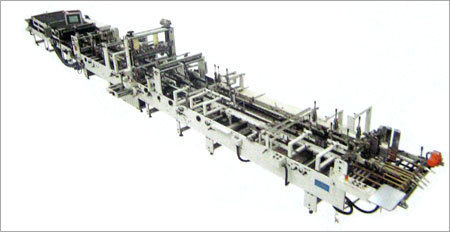

Ac Drives Automatic Folder Gluer Machine

Price:

Get Latest Price

In Stock

Product Specifications

| Model | QHZ-680 |

| Speed | High speed |

| Material | White board |

| Weight | 200-500 g/m² |

| Operation | Automatic |

| Usage | Packaging foodstuffs, pharmaceuticals, detergents |

| PLC | Yes |

| Features | High speed, Automatic operation, Reliable, Durable, Efficient packaging |

Product Overview

Key Features

We are a well-known manufacturer, exporter and supplier of Automatic Folder Gluer Machine. This machine is manufactured using quality tested components by our trained and experienced professionals. The offered machine is used for excellent packaging of foodstuffs, pharmaceutical, detergents and many more products. Along with this, the provided Automatic Folder Gluer Machine is tested and verified on different parameters before making it available to the clients.

Features:

- Quick processing

- Long service life

- Low maintenance

- High reliability

I. Introduction

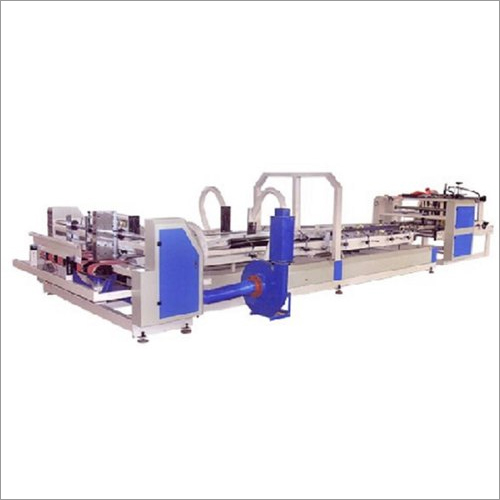

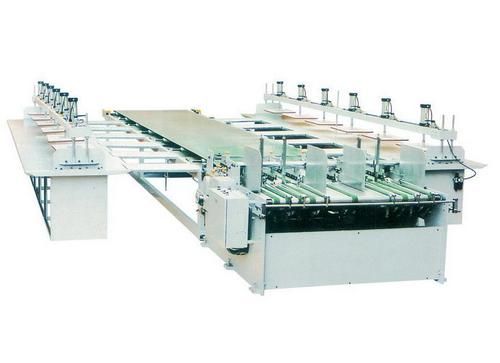

The machine adopts the most advanced international structure. With coordinating appearance, solid structure and selected materials, the machine fully meets the requirements of design. It is suitable for 4 fold, 4 fold with lock-bottom carton and different kinds of special box-like.

II. Features

1. It adopts the adjusted mechanism of fluctuated tooth-like lever, also it can be separated to micro-operate. Single panel operation is simple and fast-speed.

2. At paper outgoing, there are many straps driving oscillated motor, which can ensure constant and accurate paper feeding.

3. Two outer devices of left and right side of upper paste roller is suitable for the use of bottom sticking and side sticking.

4. Two outer devices of left and right side of bottom paste roller is suitable fort he uses of special-shape box.

5. It is equipped with travel strap and small clasp knife for your alternative.

6. It adopts frequency- conversion electric motor, PLC control system and original units and components imported from .

7. Traveling wheels of belts are machined in digitally-controlled way to avoid vibration under high speed and extend service life.

8. Spindle and connecting shaft are made of hard chromium rods to avoid cladding peel-off and assure durable appearance and stability.

9. Main drive adopts imported belt and frequency conversion motor to make sure the equipment works stably and accurately at high speed.

III. Details

Paper-feeding Part: single-panel operational mechanism is fast-speed and simple; non-pole adjustment can be done during the paper-feeding interval.

Return Folding Part: the machine adopts the design of two-plate type strap, which can pre-fold the first broken line 180 and the third broken line 135 and then extend them.

Base Sticking Part: sketching bottom stably and accurately, operate quickly and simply, produce 60-350 boxes per minute.

Bottom Paste-roller Part: left and right device ensures a stable paste volume, large capacity, easy maintenance; it is equipped with a cutting-proof blade device.

Primary Folding Part: fold the second broken line 180 and the fourth broken line 180.

Pressing part: it applies continuous box-accumulating form, adopts electro photometer to set fixed data in advance, control panel sets the data and then automatically marks the paper box .

Conveying Part: even pressing and order transmission, which can ensure perfect quality

IV. Specification

| Model | QHZ-580 | QHZ-780 | QHZ-850 |

| Function | 4-fold, side & bottom gluing | 4-fold, side & bottom gluing | 4-fold, side & bottom gluing |

| Max. unfold width (mm) | 580 | 780 | 850 |

| Min. unfold width (mm) | 70 | 120 | 150 |

| Max. speed (m/min) | 260 | 260 | 260 |

| Total power (kw) | 8.6 | 8.6 | 9.8 |

| Total weight (kg) | 4600 | 6100 | 7000 |

| Dimension (mm) | 10000x1850 | 10500x1850 | 10500x1850 |

Company Details

Focusing on a customer-centric approach, SHANTOU SHANHE INDUSTRIAL CO., LTD. has a pan-India presence and caters to a huge consumer base throughout the country. Buy Machineries in bulk from SHANTOU SHANHE INDUSTRIAL CO., LTD. at Trade India quality-assured products.

Business Type

Exporter, Importer, Manufacturer, Supplier

Employee Count

300

Establishment

1994

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Shantou, Guangdong

Sales Manager

Mrs. Joyce Zhuang

Address

Shanhe Industrial Park, Huaxincheng of Chaoshan Road, Shantou, Guangdong, 515000, China

folder gluer machine in Shantou

Report incorrect details