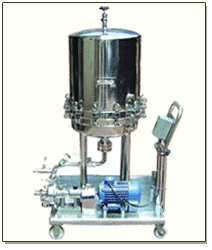

Automatic Batch Blender

Price: 1.50000 INR / Piece

Get Latest Price

Minimum Order Quantity :

1 Piece

In Stock

Product Specifications

| Temperature Range | Ambient to 60AdegC (non-heated) |

| Installation Guideline | Floor Mounted, Professional Installation Recommended |

| Model No | ABB-1000 |

| Plastic Processed | PP, PE, PET, PVC, Other Thermoplastics |

| Automation Grade | Automatic |

| Accessories | Loading Hopper, Discharge Valve, Control Panel, Level Sensors |

| Speed | Variable (controlled via VFD) |

| Frequency | 50 Hz |

| Production Capacity | 500-1000 kg/hr |

| Motor Power | 3 HP - 10 HP |

| Driven Type | Motor Driven |

| Efficiency (%) | >98% |

| Usage & Applications | Plastic Compounding, Masterbatch Mixing, Recycling, Injection Molding, Extrusion |

| Type | Automatic Batch Blender |

| Material | Stainless Steel, Mild Steel |

| Computerized | Yes |

| Automatic Grade | Automatic |

| Control System | Other, PLC Based Touch Screen Control Panel |

| Drive Type | Other, Electric Motor Driven |

| Voltage | 380V-415V |

| Power | 3 kW - 7.5 kW (depending on model) |

| Weight (kg) | Approx. 350-1000 kg |

| Dimension (L*W*H) | 1200*900*2000 mm (standard model) |

| Color | Industrial Grey/Blue or Custom |

| Capacity | Up to 1000 kg/hr (model dependent) |

| Features | Precise Batch Blending, High Accuracy, User-friendly Interface, Easy Maintenance, Modular Structure, Overload Protection, Safety Interlocks |

| Surface Finish | Other, Polished / Painted |

| Power Consumption | 5 kW (average) |

| Machine Type | Batch Blender - Gravimetric |

| Supply Ability | 10 Per Week |

| Delivery Time | 1 Week |

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

15

Establishment

1973

Working Days

Monday To Sunday

GST NO

27ARUPS7370Q1ZE

Certification

ISO 9001 : 2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27ARUPS7370Q1ZE

Mira Bhayandar, Maharashtra

Proprietor

Mr Fayazulla Z. Sayed

Members since

21 Years

Address

SHANTA INDL. ESTATE, SHED NO-1, BEHIND DODHIA PETROL PUMP, W.E. HIGHWAY, KASHIMIRA-MIRA ROAD, Mira Bhayandar, Maharashtra, 401104, India

blending machine in Mira Bhayandar

Report incorrect details