Automatic Bag Sack Emptying System - Color: Machine Gray

Price: 150000.00 INR / Set

(150000.00 INR + 0% GST)

Get Latest Price

1 Pack Contains :

1

Minimum Pack Size :

1

In Stock

Product Specifications

| Weight | 3500 Kilograms (kg) |

| Product Type | Automation |

| Size | Dimensions |

| Application | For dustfree and efficient emptying of powder or granular materials from 25aEUR"50 kg bags |

| Length | 5400 Millimeter (mm) |

| Usage | Used for safe and clean emptying of powder or granular materials from 25AC/AEURA"50 kg bags in pharmaceutical, chemical, food, and plastic industries. |

| Height | 3300 Millimeter (mm) |

| Features | Efficient and dust-free bag unloading Reduces manual handling and spillage Integrated dust extraction system Easy maintenance and quick cleaning Compact and ergonomic design Optional bag compactor or vibrating hopper |

| Color | Grey |

| Width | 3600 Millimeter (mm) |

| Phase | 3 Phase |

| Material | MS / SS304 / SS316 / SS316L |

| Power | 15 Horsepower (HP) |

| Voltage | 440 Volt (v) |

| Warranty | 1 Year |

| FOB Port | mumbai |

| Supply Ability | 6 Per Year |

| Delivery Time | 8 Week |

| Sample Policy | Contact us for information regarding our sample policy |

| Main Domestic Market | All India |

| Certifications | GST, MSME, CE |

| Brand Name | pneuCONVEYOR |

| Currency | INR |

| Packsize | 1 |

| Price Type | fixed |

| Mop | 1 |

| Returnable | No |

| Stock Quantity | 10 |

| Price | 150000.00 INR (Approx.) |

| Color | Grey |

| Moq | 1 |

| Unit Type | Set/Sets |

| Product Unit | 1 Set/Sets |

| Minimum Ordered Packs | 1 |

| Minimum Order Quantity | 1 |

| GSTIN | 0% |

Product Overview

Key Features

In Automatic Bag Emptying system operates the roller conveyor line, the entire stack will be automatically conveyed into the catching position of bag slitter, the catching device of the bag slitter will come down to grab the whole layer bags layer by layer, and raise up to the set position, then move inside the machine, during this process the cutter blade will cut open the bags from the bottom, material emptying device to empty the material inside the bag, the material by gravity fall into the hopper, empty bag into the waste bag compactor, which collect, compact and extrude out the waste bag. When the whole stack bag is unpacked, the roller conveyor line will automatically transport the empty pallet to the pallet collector to complete automatic collection and stacking of the empty pallet.

Working Process:-

Sack Loading : Bags are placed on an infeed conveyor manually or via a pallet loader.

Automatic Bag Cutting : Rotary or guillotine blades cut open the sack in a controlled enclosed chamber.

Material Discharge : Contents fall into the receiving hopper, equipped with vibration or screw feeding for continuous downstream conveying.

Empty Bag Separation : Automatic removal of empty sacks via a discharge conveyor into a compactor or waste bin.

Dust Control : Integrated dust extraction ports ensure clean and safe operation.

Continuous Feeding : Material is directly fed into the process line via pneumatic, screw, or belt conveying.

Technical Specifications :-

MODEL: PC-ABES 25-50

Capacity: 600-900 bags/hour (depending on fluidity of material)

Bag Weight: 25 Kg - 50 kg

Material handled: Powder, Granules, Flakes

Cutting Mechanism: Rotary Blades

Emptying rate: 99.9%-99.98% (depending on the fluidity of material)

Overall power: About 10KW

Compressed air: about 100L/ min / 0.6mpa

Weight of equipment: about 3 tons

Working Principle:-

Capacity: Up to 20 to A A 30 sacks/min (varies with bag size & product type)

Bag Size Range: 25 to A A 50 kg standard

Automatic Blade Cleaning System to prevent clogging

Stainless Steel Construction (SS304 / SS316L) for GMP environments

Enclosed Dust-Tight Design with HEPA filtration option

Integrated Empty Sack Compactor

PLC-based Control Panel with HMI touchscreen interface

Safety Interlocks & Emergency Stops

Low Maintenance, Long Service Life

Company Details

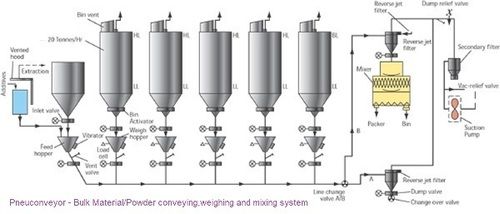

COMPANY & PRODUCT RANGE : pneuCONVEYOR âA A began its activities in the year 2010 in the field of Pneumatic Conveying system & Mechanical Conveying Systems. The company has specialized since its origins in the production and use of Pneumatic conveying & related machineries and then, over the years, extended the products & range of machinery such as Pneumatic Dense Flow conveyor (Ash conveyor / Cement Conveyor) Vacuum powder transfer system, Mixing & Bagging Machinery, Mechanical Conveyor such as (Tubular Drag Conveyor / Flexible Screw Conveyor). These services cover all activities involved in a project right from concept to commissioning. pneuCONVEYOR systems & engineers âA A with its head office at Mumbai, is fast becoming one of the leading groups in India with operational experience in execution of turnkey projects in the field of bulk Powder (fine/Coarse) conveying system for Chemical Industry, Food Industry, Pharma Industry, Coal based Power plants, Cement Industry, Pesticides Industry, Paper Industry, Plastic Industry, Paint Industry, Foundries & other core sectors. pneuCONVEYOR has extensive experience in execution of complete Powder / Granules / Fly Ash / Bulk solids Handling System in medium to large sectors on turnkey basis. This includes design & engineering, manufacture & supply, site fabrication & erection & associated structural works. INFRASTRUCTURAL FACILITIES : Our office is located in Mumbai (Maharashtra) heart of India, having factory At Bhiwandi (Thane) & GIDC sarigam (Bhilad) Gujarat. Our office as well as manufacturing works are well equipped with latest computers, scanners & printers along with server connected to all the computers having facility, enabling fast, accurate communication with client/vendor. RESEARCH, DEVELOPMENT & TESTING : Our R & D facilities enable us to develop innovative market leading solutions to meet the needs of the modern power industry. Material characteristic analysis. Extensive array of test circuit. Extensive knowledge database of materials & solutions. Our designs, products & project management meet. Customer & industry standards. QUALITY MANAGEMENT SYSTEM : AÅA emphasis is given to meet specific requirements of the customers to provide satisfaction & make concerted efforts to enhance continual improvements, technical expertise and human excellence by adopting total quality management in all spheres of the organizations activities. QUALITY OBJECTIVES : The organization is committed to achieve the quality objectives which are given below : To enhance customer satisfaction continually. To reduce the rejection and rework. Focus is on defect prevention rather than defect detection. To reduce machine breakdowns. To complete projects within the agreed duration. SCOPE OF MANUFACTURING : pneuCONVEYOR systems is a âA A solutions-orientedâA A equipment supplier, specializing in custom design and implementation of bulk material handling system in india. We are the top-notch manufacturer, supplier and exporter company that deals in the products like Pneumatic powder conveyor (Pressure/Vacuum). Mechanical conveyor (Tubular chain drag conveyor / Screw conveyor). Fly Ash/Cement conveying system (Dense / Dilute Flow system). Bulk product handling system. Milling, Sieving, Mixing machines & Equipments. Bunker, Storage Tank & Pressure Vessel. We look forward to servicing the needs of our clientâA A s production requirements!

Business Type

Exporter, Manufacturer, Supplier

Employee Count

20

Establishment

2010

Working Days

Monday To Sunday

GST NO

27AANHR8619F1ZN

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AANHR8619F1ZN

Mumbai, Maharashtra

Managing Partner

Mr R K Panchal

Address

B-23, Adke Compound, L B S Marg, Vikhroli (west), Mumbai, Maharashtra, 400083, India

Report incorrect details