Autoclaved Aerated Concrete Aac Plant

Price:

Get Latest Price

In Stock

Product Specifications

| Land area | 3 acres |

| Shed area | 20000 sqft |

| Power | 500 KVA |

| Water | 100 tons/day |

| Boiler | 4 tons |

| Materials | Fly ash, cement |

| Production | 50000 blocks |

| Features | High output, Durable blocks, Cost effective, Eco-friendly, Versatile, Easy operation, Low maintenance |

Product Overview

Key Features

Electricity required for a fly ash based aac = 500 KVA (uptp 1.5 Lakhs per annum, for basic Configuration)

Investment- 9 cr and 11 cr except land (upgradable, u can check the attached sample project profile for details)

Water required is 300 Lts per CM. Thus per day water requirement is 100 Tons of water per day.

1.autoclaved aerated concrete AAC plant Planning and design:

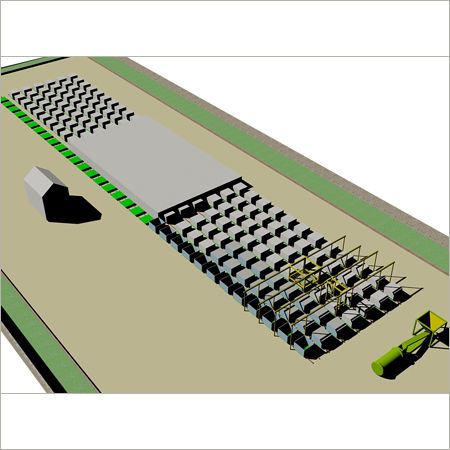

Factory covers an area of 3 acres or so.

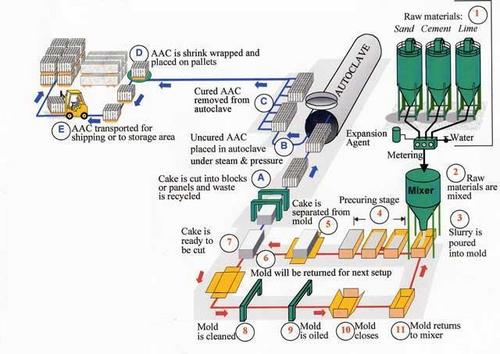

There should be raw material area, finished block area and production area. Production process includes raw material disposal, rated material pouring, curing, cutting and steaming procedure.

From building foundation to equipments installing and testing, to trial producing, it will take 4-5 months.

Plant design: 2000 m2 or so.

2.autoclaved aerated concrete AAC plant Material:

1)Flyash: get dry ash from power plant

2)Cement: cement in bulk

3)Lime, gypsum and aluminum powder (buy in local area)

3.autoclaved aerated concrete AAC plant Water, electricity and steam supply:

1)Water supply: build a well or use waste water

2)Electricity supply: install a 350kw transformer

3)Steam supply: install a 4tons boiler to supply steam to autoclave and curing room

Company Details

Business Type

Exporter, Manufacturer, Supplier

Employee Count

28

Establishment

2012

Working Days

Monday To Sunday

GST NO

21AAMFD3447L1ZD

Payment Mode

Cash on Delivery (COD)

Certification

ISO 9001: 2015

Related Products

More Product From This seller

Seller Details

GST - 21AAMFD3447L1ZD

Bhubaneswar, Odisha

Ceo

Mr Gangadhar Reddy

Members since

7 Years

Address

House No. 15, Narendra Garden, Jagamara, Near Jagamara Traffic Square, Bhubaneswar, Odisha, 751030, India

Plant & Machinery in Bhubaneswar

Report incorrect details