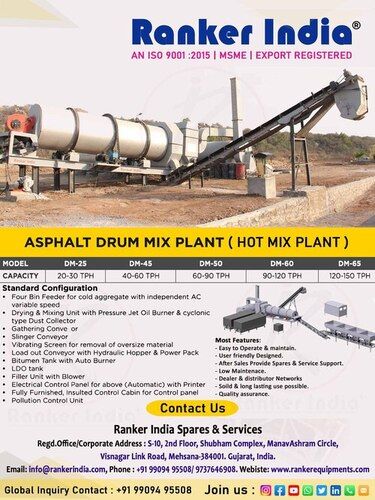

Asphalt Drum Mix Plant - Mild Steel, 30 Tons Capacity, Yellow | Automatic, Computerized, Dual Zone Thermo Drum Design, Efficient Fuel Utilization

Price: 2050000.00 INR / Unit

(2050000.00 INR + 0% GST)

Get Latest Price

1 Pack Contains :

1

Minimum Pack Size :

1

In Stock

Product Specifications

| Color | Yellow |

| Type | Asphalt Mixers |

| Material | Mild Steel |

| Capacity | 30 T/hr |

| Computerized | Yes |

| Automatic Grade | Automatic |

| Power | 440 Volt (v) |

| Payment Terms | Telegraphic Transfer (T/T) |

| Delivery Time | 1 Months |

| Main Domestic Market | All India |

| Price | 2050000.00 INR (Approx.) |

| Mop | 1 |

| Returnable | No |

| Stock Quantity | 5 |

| Color | Yellow |

| Moq | 1 |

| Brand Name | AYS |

| Unit Type | Unit/Units |

| Product Unit | 1 Unit/Units |

| Price Type | fixed |

| Currency | INR |

| Packsize | 1 |

| Minimum Ordered Packs | 1 |

| Minimum Order Quantity | 1 |

| GSTIN | 0% |

Product Overview

Key Features

Driven Type : Engine

Usage : Drum Mixing

No Of Bins Total Storage : 4

Surface Treatment : Polished

Country of Origin : India

The manufacture of hot mix demands the combination of a number of aggregates, sand and a filler (such as stone dust), in the correct proportions, heated, and finally coated with a binder, usually bitumen based or, in some cases tar. the temperature of the finished product must be sufficient to be workable after transport to the final destination. A temperature in the range of 100 to 200 degrees celsius is normal.

Design Parameters:-

The asphalt drum mixing plant offered having designed roots from barber greene company in u.s.a.; generally conforming to drum mix series. It is modern having all essential features of a latest generation hot mix plant for obtaining hot mix of designed quality for road construction works as well as in road repair and maintenance works undertaken for improving road surfaces. The plant offered is simple for erection, operation and maintenance with complete indigenous sophisticated and effective controls for efficient process control. The plant offered will meet all engineering specifications in construction and factor of safety provided as per norms.

Cold aggregate feeder

The cold aggregate feeder will have four independent bins or compartments of approximately 60 tons total capacity supported on a rigid steel frame. The feeder bins will be constructed of 5 mm thick steel plates. Each bin will be provided with a belt feeder under the bin driven by an independent and mutually synchronized 2 h.p. variable speed motor for feeding the aggregate at a uniform and predetermined rate through a precision adjustable bin quadrant gate. Each bin will deposit its aggregate on a gathering conveyor of 600 mm wide belt driven by 5 hp electric motor

Single deck vibratory screen

Single deck vibratory screen is provided at the discharge end of the gathering conveyor to enable rejection of any oversize material above the permissible limit before loaded on the slinger conveyor and to the drier.

Slinger conveyor (feed conveyor)

A slinger conveyor with 500 mm wide belt will be provided for transferring the aggregate received from the gathering conveyor and discharging it into dryer under combustion zone. The slinger conveyor will be driven by a 5 h.p. electric motor. A continuous electronic weigh-bridge with load cells will be mounting on the slinger conveyor for weighing accurately the aggregate. The equipment will monitor the weight of aggregate fed in the drum and indicate the same in tons per hour along with a cumulative read out and a totaliser.

Dryer and mixing unit

The dryer and mixing unit will be of a dual zone thermo drum design, cylindrical drum mounted on a sturdy and robust steel structure. Fabricated from boiler quality plates of 10 / 12 mm thick, the thermo drum will be divided into two energy zones; a radiation zone and a convection/coating zone by a radiation shield. The greatest concentration of heating energy will be in the radiation zone where it will be applied to the cold, wet aggregate and most of the heating and drying will take place therein. Bitumen will be injected in the convection/coating zone, which is protected from the direct flame of the burner by the radiate heat shield, and mixing; heating and drying will be completed. The dryer will be designed for maximum fuel efficiency and heat transfer while preventing blue smoke emission problems. It will produce a superior quality hot mix. the flights in the different zones will be designed exclusive and uniquely to work together to assure that a properly controlled veil of aggregate is maintained during operation. a the exterior of the thermo drum shall be insulated with ceramic wool and cladding is done with stainless steela .

Company Details

It gives us immense pleasure to introduce our company - AYS Equipments as one of the leading supplier of Road & Building construction equipment. We are also a leading supplier for Spare Parts of Self Loading Concrete Mixer, Backhoe Loader & Stone Crusher Etc.

Business Type

Manufacturer, Service Provider, Supplier

Employee Count

12

Establishment

2020

Working Days

Monday To Sunday

GST NO

01AVAPP5097R1Z1

Payment Mode

Cheque

Certification

ISO 9001:2015

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 01AVAPP5097R1Z1

Jammu, Jammu and Kashmir

Director

Mr Sunil Pandita

Members since

2 Years

Address

195, 1st Floor, Lower Roop Nagar, Sector - 1, Jammu, Jammu, Jammu and Kashmir, 180013, India

Report incorrect details