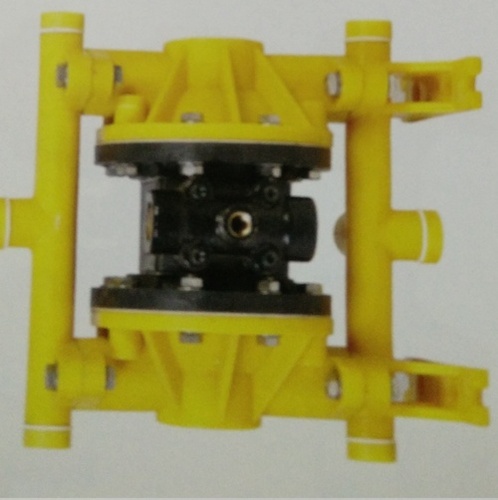

Air Operated Double Diaphragm Pumps By Antlia Engineering Works

Price: 32000.00 INR

(32000.00 INR + 0% GST)

Get Latest Price

1 Pack Contains :

1

Minimum Pack Size :

1

In Stock

Product Specifications

| Model | AODD 15, AODD 30, AODD 40, AODD 50, AODD 75 |

| Material of Construction | PP, SS, PVDF, AL |

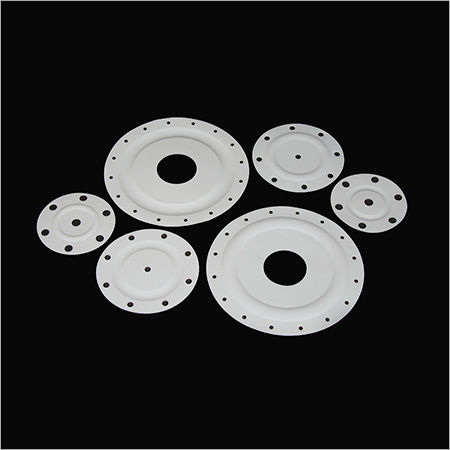

| Diaphragm | PTFE/Rubber |

| Suction & Discharge | 1"-3" |

| Air Inlet | 1/4"-1" |

| Max Flow | 33-440 LPM |

| Discharge Pressure | 3-6 Kg/sq.cm |

| Head | 30-60 meter |

| Suction Lift | 1.8-5.8 meter |

| Max Solid Size | 2.5-10 mm |

| Features | Versatile fluid transfer, Handles solids easily, Durable construction, Lube free operation, Non-stalling valves, Wide range applications, Emergency pump option |

| FOB Port | Mumbai |

| Payment Terms | Telegraphic Transfer (T/T), Others, Cash in Advance (CID), Cheque, Cash Advance (CA) |

| Supply Ability | as per order Per Month |

| Delivery Time | 1 Week |

| Packaging Details | Bubbles /Boxes packing |

| Main Export Market(s) | Australia, North America, Eastern Europe, Middle East, Africa, Central America, South America, Western Europe, Asia |

| Main Domestic Market | All India |

| Stock Quantity | 15 |

| Unit Type | Piece/Pieces |

| Mop | 1 |

| Price Type | fixed |

| Packsize | 1 |

| Currency | INR |

| Moq | 1 |

| Price | 32000.00 INR (Approx.) |

| Product Unit | 2 Piece/Pieces |

| Returnable | No |

| Brand Name | ANTLIA ENGINEERING |

| Minimum Ordered Packs | 1 |

| Minimum Order Quantity | 1 |

| GSTIN | 0% |

Product Overview

Key Features

The Air Operated Double Diaphragm Pumps are best solution for those applications that need more than fluid transfer. All the solids, viscous or sticky media present in water will be easily handled with these pumps. Widely used in automotive industry, Beverage Industry, Chemical Industry and various other industries, these pumps are excellent calamity and emergency pumps available in the market. Made from aluminum, cast iron and stainless steel, this Air Operated Double Diaphragm Pumps are absolutely lube free and non-stalling valve pumps.

TECHNICAL SPECIFICATION:

| MODEL | AODD 15 | AODD 30 | AODD 40 | AODD 50 | AODD 75 |

|---|---|---|---|---|---|

| MOC | PP,SS,PVDF,AL | PP,SS,PVDF,AL | PP,SS,AL | PP,SS,AL | ALUMINIUM |

| DIAPHRAGM | PTFE/Rubber | PTFE/Rubber | PTFE/Rubber | PTFE/Rubber | PTFE/Rubber |

| SUCTION & DISCHARGE | 12 inch | 1 inch | 1 12 inch | 2 inch | 3 inch |

| AIR INLET | 14 inch | 14 inch | 12 inch | 34 inch | 1 inch |

| MAX FLOW | 33 LPM | 60 LPM | 140 LPM | 300 LPM | 440 LPM |

| DISCHARGE PRESSURE (Kg/sq. cm) | 3 | 6 | 6 | 6 | 6 |

| HEAD (meter) | 30 | 60 | 60 | 60 | 60 |

| SUCTION LIFT | 1.8 | 4.8 | 5.5 | 5.8 | 5.8 |

| Max Solid Size in (mm) | 2.5 | 3.4 | 5 | 6.5 | 10 |

WORKING PRINCIPLE:

A: Left Stroke

The double diaphragm pump has two diaphragms A and B. The air valve handle the pressurized air to the back side of Diaphragms A. It is act as a separation member between the compressed air and liquid and then removing all the mechanical stress from the diaphragms. The compressed air is directly applied to the liquid column which is further separated by elastomeric diaphragms. After separation, the compressed air moves the diaphragms away from the center block of the pump. The diaphragm on the opposite side pulled in by the shaft connected to the pressurized diaphragm. Moreover, Diaphragms B on its suction stroke forced out the air through the exhaust port of the pump.

Diaphragm B move towards the center block of the pump which creates a vacuum within the chamber B. The liquid is completely free to move past the inlet ball and fill the liquid chamber.

B: Mid Stroke

When the diaphragm A reaches its discharge limit, the air valve redirect the pressurized air to the back side of the Diaphragm B. After that, the pressurized air forces B diaphragm away from the center block at the time of pulling diaphragm A to the center block. Now, diaphragm B is on its discharge stroke. Because of hydraulic forces developed in the liquid chamber, the diaphragm B forces the inlet valve ball onto its seat. This hydraulic force lift the ball off its seat while the opposite ball valve forced onto its seat to flow through the pump discharge. The Diaphragm A move toward the center block of the pump which creates a vacuum withing the liquid chamber.

When atmospheric pressure forces the liquid into the inlet manifold of the pump and the inlet ball valve is forced onto its seat which further forcing fluid to flow through the pump discharge.

C: Right Stroke

When all strokes completed, the air valve again redirects the back side of the Diaphragms A, which again starts diaphragms B on its exhaust stroke. When pump reaches its original starting point, both diaphragm has gone through one exhaust & one discharge stroke. It represents one complete pumping cycle.

INDUSTRIAL APPLICATION

1: Chemical & Refineries

The Double Diaphragm pump handle different types of chemical like bases, solvents, acids and alkalis, resins and adhesives, high-density liquids & viscous products. In addition, it can also transfer oil skimming,storm water, seawater, oil sludge, latex, insecticides, corrosion inhibitors,drainage water, fertilizer, pesticides, and more.

The diaphragms pump also find its application in pumping raw materials, storm water, unload trucks and tank and used to be used in waste water treatment , scrubber's application and filter press.

2: Waste Water Treatment

In water treatment industry, our AODD pumps are used in municipal and industrial waste-water treatment plants. Fluids that are put into the pumps are high in viscosity and require pumps that handle those liquids. The double diaphragm pumps also help to pump polymers, acids and slurries at the time of water treatment process that is used to treat water.

3: Food & Beverages

In food industry, this pump is used for different food processing applications. It can also be used for transferring food products such as tomato pulp, ham pulp, vinegar, pet food, vegetable oil, honey, vitamins, wine, fruit pulp, fruit juice, decaffeination, rennet and many more.

Air operated double diaphragm pump are used in the food and beverage industry for various food processing application. This pumps can be used for transferring food products like chocolate, soft drinks, ham pulp, vinegar, pet food, yeast, eggs, vegetable oil, honey, vitamins, glucose syrup, concentrates, decaffeination, fruit pulp, fruit juice, rennet, aromas and more.

In addition to food, this pump can be also used for pumping chemicals such as nitric acid, hydrochloric acid, caustic soda, antioxidants & brine and waste products such as animal blood, waste water and sludge. They are widely used in the CIP (cleaning in place) plants, food processing, and waste water treatment & slaughtering.

4: Paints & Coating

It is widely used in paint industry considering their ability to move viscous fluids such as ink, acrylic, primers and coatings. The main applications that we can find in this field are inks maker, spray systems, printing machines and cleaning baths.

5: Pharmaceutical

In Pharmaceutical field, it is one of the main system for pumping fluids. AODD pump can easily handle proteins, vegetable extracts, flavors, enzymes, vitamins, chemicals, ointments, alcohols, additives, disinfectants, waste solvents, blood plasma, waste fluids and more. One of the main applications are filtering aids, aseptic transfer, tablet coating, ultrafiltration, reactors for the production & waste water treatment.

6: Steelworks & Foundries

In Steelworks & Foundries it is used in flushing of cores, rolling mills, mold release and galvanizing which are using positive displacement pumps. The pneumatically operated pumps can transfer different fluids in dust scrubbing slurry, rust inhibitors, grinding, drainage water and cutting oils.

7: Cosmetics & Cleaning

In Cosmetics & Cleaning, it is used to pump lots of fluids starting from the raw materials and end products up to additives and chemicals. Main fluids are surfactants, fabric softener, lotions, creams, shampoos, hair permanents, emulsions, disinfectants, detergents, gels, soaps, foaming agent and others more.

8: Semiconductor & Electronics

Fluids like ultra pure liquids, sulphuric acid, waste liquid, stablizers anodic sludge are some important fluids which required to be taken care in Semiconductor & Electronics industry.

Its common applications are ultrasonic washing and electroplating baths.

9: Textile & Tanning

In the Textile and Tanning industry, this pump is used for dosing the chemicals such as formic acid, ammonia and solvents but also for pigments, ink and paint. Its main application includes coloring, dosing of chemicals, ink maker, processing fluids, waste water treatment as well as unload truck.

10 Galvanic

In Galvanic, the diaphragm pump find its wide usage in moving chemical aggressive fluids including waste products which contains metallic solid parts. Its typical applications are electrostatic plating, galvanic baths, surface treatment, polishing, filtering system and waste fluids.

11: Pulp & Paper

Pulp & Paper is another main field where AODD pump is used to transfer additives,ink and paint, and the chemicals.

12: Constructions & Mining

In Constructions & Mining, the AODD pump is requires for heavy duty performance, abrasion resistance as well as solids-handling capabilities. It helps to increase productivity by remaining dependable even while handling these tough jobs.

13: Energy & Power Plant

In Energy & Power Plant, AODD pump is mainly used in bio-gas, chemical transferring and bio fuel plants, fuel cells, battery manufacturer, denitrification, and waste water treatment.

14: Automotive

In Automotive industry, it is also used for moving oil emulsion, coolant, hydraulic fluid, additives, glycol and waste oil. Its main applications include, tank and car washing, oil/water separators, degreasing baths, and many more.

Company Details

The Antlia Engineering Works opened its doors with owning the entire process from manufacturing to delivery ensuring utmost quality and customer gratification. Antlia pumps are safe-efficient-reliable and any broken parts can be easily replaced with genuine Antlia spares. As a result, they are used in a wide range of industries to handle different materials such as chemicals, crude oil, mining, food, beverage, paints and many more.

Business Type

Manufacturer, Distributor, Supplier, Trading Company, Wholesaler

Employee Count

5

Establishment

2017

Working Days

Monday To Sunday

GST NO

27AQYPJ2651A1ZS

Payment Mode

Cash Advance (CA), Telegraphic Transfer (T/T)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 27AQYPJ2651A1ZS

Mumbai, Maharashtra

Proprietor

Mr Meet Ramesh Jain

Address

208. 2nd Floor, Resham Bldg, Station Road, Goregaon West, Mumbai, Maharashtra, 400062, India

air operated diaphragm pump in Mumbai

Report incorrect details