Tilting Table - Accuracy: 1 °C

Price: 2360.00 INR / Piece

(2000.00 INR + 18% GST)

Get Latest Price

MRP:

2360.00 INR / Piece

Weight :

1200.00 Kilogram

1 Pack Contains :

1500

Minimum Pack Size :

30

In Stock

Product Specifications

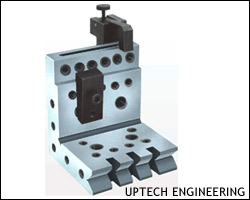

| Control System | Tilting tables come with different control systems based on their type. Manual models use handwheels or levers for angle adjustment. Motorized versions feature push-button or switch-based controls for easy operation. Advanced models use PLC or HMI-based systems for automatic tilt control, preset angles, speed adjustment, and remote operation. Hydraulic tables include valves and regulators for smooth movement. The control system ensures precision, safety, and ease of use in various industrial applications. |

| Accuracy | 1 AdegC |

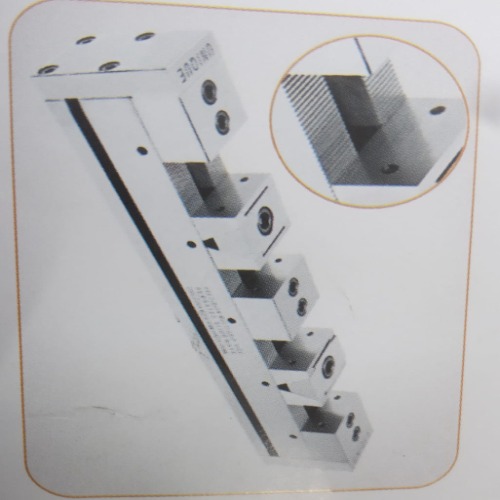

| Machine Type | A tilting table is a versatile tool widely used in various industrial applications where angular positioning of the workpiece is essential. Its primary function is to tilt heavy or complex components to a desired angle for ease of machining, welding, assembly, or inspection. In the manufacturing sector, tilting tables are commonly integrated with CNC milling machines, drilling machines, and grinding machines to enable precise angular operations. In welding and fabrication shops, they allow operators to comfortably position jobs for high-quality welds. Tilting tables are also extensively used in precast concrete production, where large concrete panels are cast flat and then tilted vertically for removal and installation. Additionally, they are useful in inspection setups, electrical panel fitting, and sheet metal work. In the medical field, tilting tables are used in diagnostic procedures such as tilt table tests. Depending on the application, they can be manual, motorized, or hydraulic, and may also include rotation features for multi-axis functionality. |

| Automation Grade | Tilting tables are available in different automatic grades based on the level of control and automation required for specific applications. The most basic is the manual tilting table, where the angle is adjusted using a handwheel or screw mechanism. For higher efficiency and precision, semi-automatic tilting tables feature motorized tilt controlled by simple switches or foot pedals, often with limiters or angle stops. The most advanced are fully automatic tilting tables, which are equipped with electric motors, hydraulic actuators, and programmable control panels (PLC or HMI-based systems). These tables allow pre-set angles, automatic tilt sequences, and remote operation, ensuring consistent results in repetitive tasks like CNC machining, welding, or concrete casting. The choice of automatic grade depends on workload, job precision, frequency of use, and integration with other machinery. |

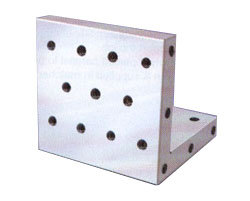

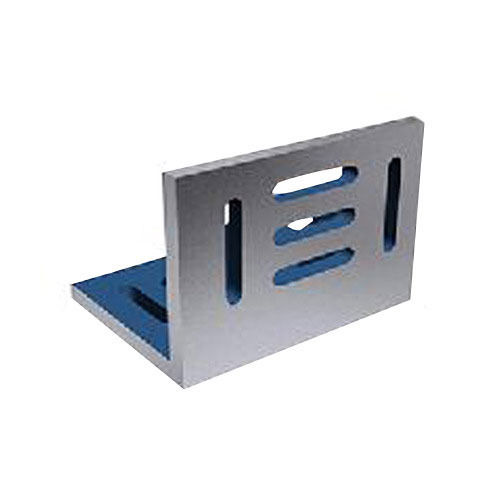

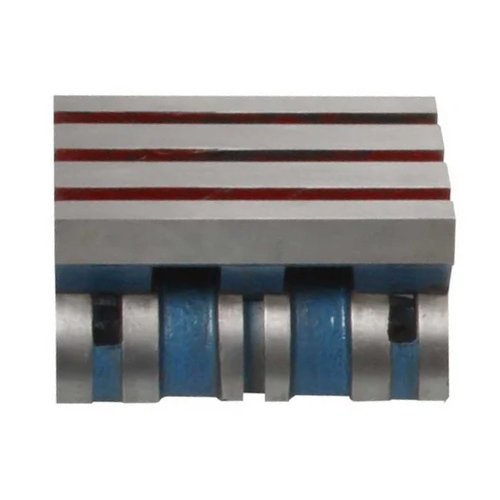

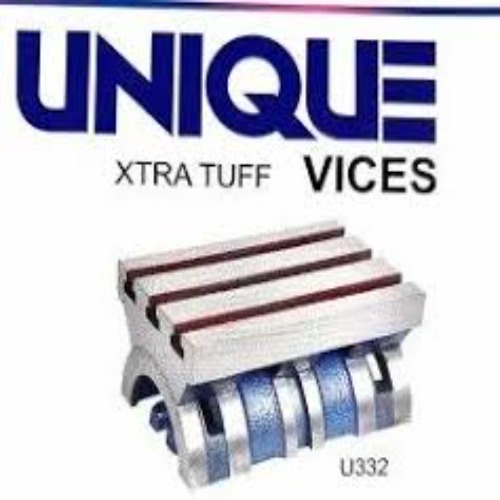

| Color | SILVER/BULE |

| Surface Treatment | Polished |

| Power Source | 220 V |

| Features | Tilting tables are designed for versatility, strength, and precision. Key features include a tilt range of 0 to 90 , heavy-duty construction (usually cast iron or steel), and T-slots for secure clamping. They offer smooth manual or motorized tilting, angle graduation or digital display, and locking mechanisms for safe positioning. Advanced models may include PLC/HMI control, hydraulic or electric actuators, and custom load capacities ranging from 100 kg to several tons. |

| Accessories Type | Tilting tables can be equipped with various accessories to enhance functionality and ease of operation. Common accessories include T-slots or clamping fixtures for securing workpieces, angle indicators or digital protractors for precise angle measurement, and limit switches for controlled tilt range. Advanced models may feature remote control panels, digital angle displays, and rotary attachments for combined tilt and rotation. For safety and efficiency, locking mechanisms, lifting hooks, and anti-slip platforms are also available. These accessories make the tilting table more versatile and user-friendly in industrial environments. |

| Usage | Industrial |

| Type | Manual Tilting Table Tilting is done manually using a handwheel or screw. Suitable for lighter jobs. |

| Size | 15x10 Inch |

| Material | Cast Iron |

| Height | 900 Millimeter (mm) |

| Product Type | Tilting Table |

| Weight | 1199 Kilograms (kg) |

| Function | A Tilting Table is a specialized platform designed to tilt, position, and support workpieces at various angles. It plays a key role in improving precision, accessibility, and operator comfort during manufacturing and assembly processes. |

| Width | 5 Foot (ft) |

| Length | 2133 Millimeter (mm) |

| Voltage | 220 Volt (v) |

| FOB Port | TKD |

| Payment Terms | Cash in Advance (CID) |

| Supply Ability | 10 Per Month |

| Delivery Time | 15 Days |

| Sample Available | No |

| Sample Policy | Contact us for information regarding our sample policy |

| Packaging Details | CORRUGATED CORASIS |

| Main Export Market(s) | Middle East |

| Main Domestic Market | All India |

| Certifications | Tilting tables are widely used in industrial, fabrication, and precision engineering applications. To ensure quality, safety, and compliance with industry standards, certified tilting tables are preferred. Key certifications include ISO 9001:2015 for quality management systems, CE certification for compliance with European safety and environmental standards, and ISO 45001 for occupational health and safety. In India, MSME/Udyam registration is often included for manufacturer credibility. For motorized models, electrical safety certifications such as BIS (Bureau of Indian Standards) and IP ratings (e.g., IP54 or IP65) ensure safe operation. Additional documents like load test certificates, material test reports, and warranty certificates further establish product reliability. These certifications collectively guarantee that the tilting table meets national and international standards, making it suitable for both domestic use and export markets. |

| Product Unit | 30 Piece/Pieces |

| Packsize | 1500 |

| MRP | 2360.00 INR |

| Pkg Box Breadth | 60.00 Inches |

| Stock Quantity | 150 |

| Shipping Type | actual |

| Moq | 30 |

| Price | 2000.00 INR (Approx.) |

| Currency | INR |

| Returnable | No |

| Mop | 30 |

| Brand Name | UNIQUE |

| Color | SILVER/BULE |

| Pkg Box Length | 84.00 Inches |

| Price Type | fixed |

| GSTIN | 18% |

| Pkg Box Height | 36.00 Inches |

| Unit Type | Piece/Pieces |

| Weight | 1200.00 Kilogram |

| Minimum Order Quantity | 30 |

| Minimum Ordered Packs | 30 |

Company Details

We GURU NANAK MACHINE TOOLS are engaged in manufacturing and supplying of quality range of industrial using equipments since 1980. The company stated giving excellent machine tools products in different states of Indian market. These products are designed with precision and are widely used automobile sector, textile industry and marine industry. Having vaste experience of 40 years, We are quality conscious company, which believes in delivering quality equipments to our esteemed clients In related industries. Hi-tech facilities, proven expertise, and assiduous professionals have enabled us to offer machining components as per international quality standards. Be it non-cylindrical or special component, our professionals provide solution to all work holding problems. We provide regular training to our professionals so that they can undertake calibration and retrofitting services with ease and accuracy. Our Products are manufactured at a most sophisticated plant well equipped with modern CNC machines and with updated measuring instruments. Strict quality control measures applied from raw materials purchase, its inspection, machining, heat treatment, fitting, final inspection and despatch assure international level quality to the satisfaction of our valued customers.

Business Type

Exporter, Manufacturer, Supplier, Trading Company, Wholesaler

Employee Count

10

Establishment

1982

Working Days

Monday To Saturday

GST NO

07AAUPS5242C1ZH

Payment Mode

Wallet & UPI, Cheque/DD, Online Payments (NEFT/RTGS/IMPS)

Related Products

Explore Related Categories

More Product From This seller

Seller Details

GST - 07AAUPS5242C1ZH

Delhi, Delhi

Accepts only Domestic inquiries

Sales Manger

Mr Gurpreet Singh

Members since

2 Years

Address

PLOT NO.177, BLK-H, SEC-3, BAWANA DSIIDC, Delhi, Delhi, 110064, India

Report incorrect details