Acrylic Processing Aid - Core-shell Structure With 1 To 8 Million Molecular Weight, Improved Melt Strength And Surface Quality For Pvc Products

Price:

Get Latest Price

In Stock

Product Specifications

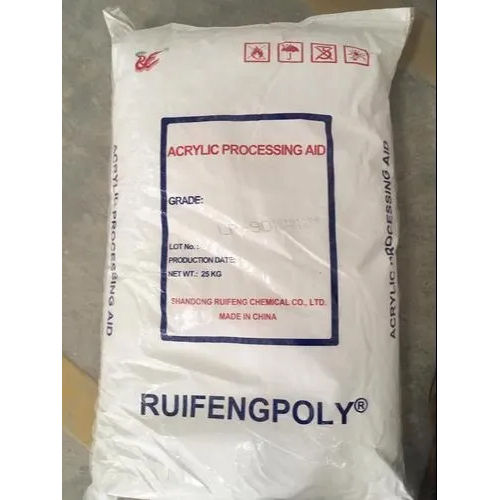

| Product Type | Acrylic Processing Aid |

| Physical Form | Powder |

| Application | Industrial |

Product Overview

Key Features

Key Benefits of Acrylic Processing Aid

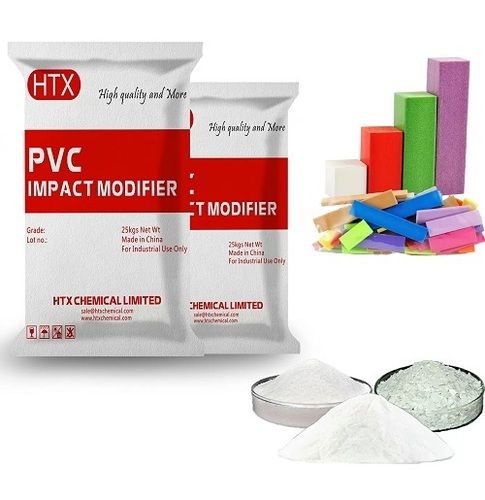

ACR used in pvc products to promote faster fusion, increases melt strength, enhances extensibility and improves melt homogeneity.

Significantly increases the surface quality of PVC products,offering excellent wall-thickness control and good thermoforming capabilities .Accelerate fusion rate, increase productivity and decrease processing temperature.

Excellent clarity and surface quality for end-use products, superior fusion promotion for rigid and soft PVC.Increased output rates and improved production efficiency.

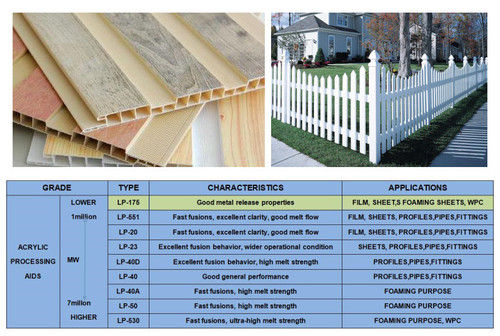

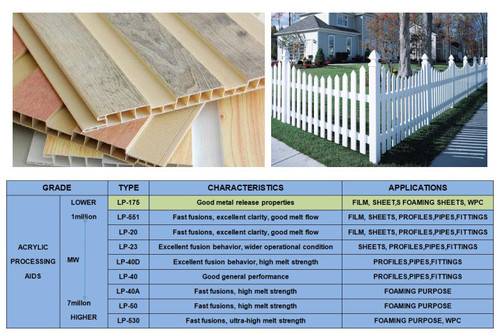

Selection of different molecular weights

Low Molecular Weight: Ideal for applications requiring transparency, such as transparent films and sheets.

Medium Molecular Weight: Suited for general PVC products, including pipes, fittings, and profiles.

High Molecular Weight: Designed for foam products like PVC foam boards, sheets, and Wood-Plastic Composites (WPC).

Industry-Equivalents:

Our ACR product lineup includes high-quality equivalents to industry benchmarks:

HPA-175: Equivalent to Dow K-175, Kaneka PA-101, and Arkema P-770.

HPA-551: Comparable to Arkema P-551, LG PA910, and Baerlocher 3FK.

HPA-20: Corresponding to Dow K-120ND, Kaneka PA20/PA210, LG PA821.

HPA-125: Matching Dow K-125, Kaneka PA-21/PA-310, LG PA-828, and Baerlocher 10F.

HPA-533: Equivalent to Dow K-128 and Arkema P-533.

HPA-40: Comparable to Dow K-400, LG PA930, and Baerlocher 20F.

HPA-100: Corresponding to Dow K435, Kaneka PA-60/PA-610.

HPA-901:PVC foam board application.

Company Details

Business Type

Exporter, Manufacturer, Distributor, Supplier, Trading Company

Employee Count

600

Establishment

2023

Working Days

Monday To Sunday

Related Products

Explore Related Categories

More Product From This seller

Seller Details

Zibo, Shandong Sheng

Director

Mr. Ben

Members since

3 Years

Address

Yiyuan Economic Development Zone, Zibo, Shandong Sheng, 256100, China

acrylic processing aid in Zibo

Report incorrect details