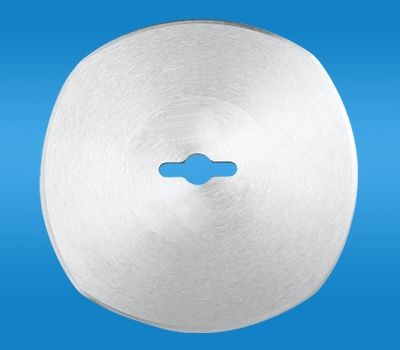

2 Axis Pipecutter

Price:

Get Latest Price

In Stock

Product Specifications

| Dimensions | Length: 10ft |

| Material | Steel, Aluminum |

| Power | 220V/3ph |

| Weight | 1500lbs |

| Control system | Computerized |

| Cutting speed | Variable |

| Accuracy | +/- 0.01 inch |

| Features | Precise cuts, Increased speed, Customizable cuts, Easy operation, Reliable system, Durable design, Improved accuracy, High efficiency, Remote controls |

Product Overview

Key Features

2 Axis Pipecutter

With Two-Axis Computer Control and manually controlled bevel angles

The W-242 is controlled by a heavy-duty industrial computer designed to run in extremes of temperature, humidity and vibration. The bevel angles are preset on the indicator gauge rather than computer controlled like the four axis W-242. Where thick pipe is used and the bevel gap must be precisely controlled for deep weld penetration the W-244 is preferred.

All controls are remotely mounted at the cutting head for easy access. The W-242 uses the latest computer motion-control systems along with an innovative floating headstock and cutting head design. Only a floating headstock and cutting head allows smooth accurate handling of irregular pipe.

This easily programmable system is accurate, reliable, easily maintained and easy to operate. With this machine you can cut any contoured pipe-end in minutes. By using the simple computer menu you can also set up saddle holes, slots, rectangles or other custom cuts.

Cutting shapes can include T's, full Y's, K's, straight cuts, miters, 90 degree saddles, mitered saddles (laterals), off-set saddles, holes, saddle holes, mitered saddle holes, slots, rectangles, and crosses. Intersections of four pipes or more can be set up in minutes.

All of these cuts can be set up with minimal training and are easily repeated later. Once a pipe is set up with multiple operations the entire job can be saved on the rugged flash memory card for recall later. Literally thousands of patterns can be stored on the machine. Multiple holes and cuts are made in perfect dimensional relationship to one another. You can also reload a partial job and retrace the steps back to where you left off.

Unlike most mechanical systems, the torch cutting speed remains constant even on steep angles. This computer precision assures fast cutting speeds and a smooth cut. Piercing is done off the cutting line for a clean edge. The unique drive system is based on a gimbaled clamping system which floats vertically and horizontally. This provides smooth positive rotation even with badly out-of-round or curved pipes. This system also prevents the pipe from walking lengthwise away from the drive clamp. This system is superior to fixed chuck drive systems which can be erratic when driving an oval pipe against the carriage wheels. The cutting head also floats mechanically on the pipe surface for accurate torch tip standoff control

When you buy a W-242 you can be assured you will easily triple or quadruple shop production compared to hand-cut pipe. You can also count on great customer support and service from one of the oldest pipe cutting equipment suppliers in the business.

Company Details

Focusing on a customer-centric approach, MEHTA SANGHVI & CO. has a pan-India presence and caters to a huge consumer base throughout the country. Get Cutting Tools, Broaches & Cutters from MEHTA SANGHVI & CO. at Trade India quality-assured services.

Business Type

Exporter, Importer, Service Provider, Distributor, Supplier, Trading Company, Wholesaler, Retailer

Employee Count

14

Establishment

1967

Working Days

Monday To Sunday

GST NO

27AAEFM5114F1ZL

Related Products

More Product From This seller

Seller Details

GST - 27AAEFM5114F1ZL

Mumbai, Maharashtra

Mrs. H. K. Sanghvi

Members since

5 Years

Address

Unit no 21, Ground Floor, Gokul Industrial Estate,Plot No. 150, Marol, M.V. Road, Andheri (E), Mumbai, Maharashtra, 400059, India

Cutting Tools, Broaches & Cutters in Mumbai

Report incorrect details