- Tradeindia

- Machine Tools

- Work Rolls

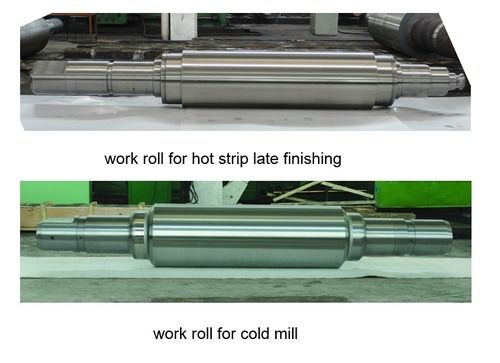

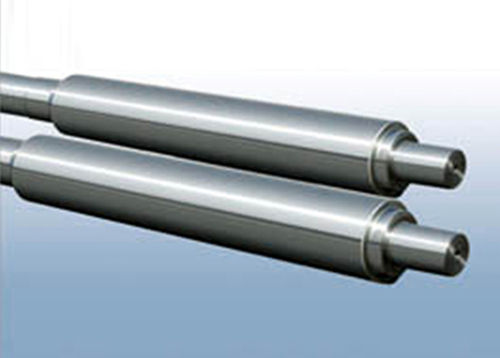

Work Rolls

(81 products)Heavy Duty Machine Work Rolls - Color: Silver

MOQ1 Unit/Units

UsageIndustrial

MaterialSteel

SizeVarious

WeightDiffer as per size Kilograms (kg)

ColorSilver

FeatureHigh Quality

4 Hi Work Roll - Color: Silver

Price: 60000 INR/Piece

MOQ1 Piece/Pieces

UsageIndustrial

ColorSilver

MaterialStainless steel

TechniqueHot rolled

FeatureDurable

View More

Forged Steel Backup Work Roll - Color: Silver

Price : 65000 INR

Mild Steel Work Roll - Hot Rolled, Silver Color | Durable Design for Heavy Load Industrial Applications

Price : 52000 INR

Forged Steel Work Rolls - Color: Golden

Price : 50000.00 INR

Work Rolls - AISI D2 Hardness 63-64 RC , Zero Roll-Failure with Extended Life by 30-40%

MaterialAISI D2

Hardness63-64 RC

TemperingHigh Temp

Roll TypeMV Grade

DowntimeZero

Scrap GenerationZero

Metal Finest Quality Work Rolls

MaterialAlloy steel

Diameter100-500mm

Length1000-3000mm

Surface finishRa 0.4µm

Hardness58-62HRC

Tolerance+/-0.1mm

View More

High Mill Work Rolls

Get Best Deal

Plate Work Rolls

Get Best Deal

High Mills Work Rolls

Get Best Deal

Work Rolls

Get Best Deal

Plate Work Rolls

MaterialForged Steel

Diameter Range50-200 mm

Length Range500-2000 mm

Surface FinishMirror Polished

Hardness60 HRC

UsagePlate metal rolling, shaping, and forming operations.

View More

6 Hi Mill Work Rolls

Get Best Deal

4 Hi Mill Work Rolls

Get Best Deal

Silver Work Roll Of Plate Ending Machine

Product TypeWork Roll of Plate Ending Machine

Material9Cr2Mo, 86CrMoV7, MC3, MC5.

Drive TypeManual

FeatureSimple Control

ColorSilver

View More

Forged Cold Work Roll

Get Best Deal

Forged Work Silver Roll Application: Machine Parts

Get Best Deal

Induction Hardened And Tempered Cold Rolling Mill Work Rolls - Steel, Varying Sizes | 5 Ton/Day Capacity, Computerized Quality Control, Enhanced Efficiency and Durability

Price: 70000 INR/Pair

MOQ2 Kilograms/Kilograms

SizeVary

Product TypeRoller

ColorOther

MaterialEn31 & En19

ComputerizedYes

Capacity5 Ton/day

Work Rolls - EN-31 & K310 Material | Optimized for SS Cold & Hot Rolling Mills, Aluminium Rolling Mills, Tube Mills

MaterialEN-31, K310

DiameterVariable

LengthVariable

Hardness60-65 HRC

Surface FinishRa 0.8µm

UsageSS & Aluminium rolling mills, Tube mills

View More

SS Work Rolls

Get Best Deal

Cold Mill Work Rolls

FeaturesHigh Quality, Durable Rolls, Precise Forging, Ultrasonic Tested, Long Lifespan, Vacuum Degassed, Strict Standards

View More

Cold Strip Work Rolls

Get Best Deal

Six High Mill Work Rolls

Get Best Deal

Forged Work Rolls

Get Best Deal

Plate Work Rolls

Get Best Deal

FAQs Related to Work Rolls

Who are the top work rolls manufacturers in India?

- H C & Company

- Tool Tech Industries

- Bajrang Tools And Rolls Pvt. Ltd.

- Perfect Roll Industries

- Horizon Global Trade

Which cities have the largest number of work rolls suppliers?

- Mumbai

- Kolkata

- Ahmedabad

- Faridabad

- Howrah

- Thane

- Indore

- Wuxi

- Beijing

- Luoyang

- Jiaozuo

- Xiangfan

How many trusted sellers are available for work rolls?

- HORIZON GLOBAL TRADE

- PERFECT ROLL INDUSTRIES

- H C & COMPANY

- TOOL TECH INDUSTRIES

What is the minimum order quantity for work rolls?

Do listed companies have registration & certifications?

- KEC FORGINGS PVT. LTD.

What is the get latest price feature?

What types of payment methods are accepted by the work rolls suppliers?

Work Roll And Leveller

MaterialSteel

Diameter100-200 mm

Length500-1000 mm

Surface FinishRa 0.8

Tolerance+/-0.1 mm

UsageSheet metal rolling, automotive parts manufacturing.

Work Rolls

MaterialPremium Raw

CustomizationVarious Forms

Tensile StrengthHigh

OperationsReliable

HardnessHigh

FinishFlawless

View More

Cold Rolling Mill Work Rolls - Premium Quality Manufacturing , High Tensile Strength and Corrosive Resistance

Get Best Deal

Skin Pass Rolls

Get Best Deal

Skin Pass Rolls

Get Best Deal

Superior Quality 4 Hi Mill Work Rolls

MaterialHigh Grade

DimensionAccurate

DurabilityExcellent

StandardIndustry

Type4 Hi

QualitySuperior

View More

4 Hi Mill Work Rolls

Get Best Deal

Backup Work Roll

Product DescriptionThese Backup Work Rolls are available with following features :\015\0121,Heat treatment : \015\012Surface of neck : 58-62HRC\015\012Surface of body and end : 62-65HRC.\015\0122,Retain centre drilling, depth of quench-hardened case >10 mm\015\0123,Surface of body and neck : no crack, spot, scratch

Work Rolls - Up to 400 mm Diameter, Up to 3500 mm Length | High Strength, Corrosion Resistant, Customizable Finishing

MaterialSteel

DiameterUp To 400Mm

LengthUp To 3500Mm

FinishFlawless

Applications2Hi,4Hi,6Hi Mills

ManufacturingPrecision

Work Roll - Superior Grade Steel , Widely Appreciated for Quality and Durability

MaterialAlloy steel

DiameterVariable

LengthVariable

Hardness60-65HRC

Surface finishRa 0.2μm

Tolerance+/-0.05mm

Beijing Honglilong Metallurgical Machinery Technology Co.ltd

Beijing

Work Roll - 9Cr2Mo Material, HRC63~65 Surface Hardness | Ideal for Plate Roll Tension Leveler and Non-Ferrous Metal Bending Application

Material9Cr2Mo

Surface QuenchingHrc63~65

Quenching Depth3~5Mm

Intermediate RollHrc62~64

ApplicationPlate Roll

Metal BendingAvailable

Veneer Reeling Working Rolls

MaterialHigh Grade

CustomizationAvailable

DurabilityHigh

ApplicationVeneer Reeling

PriceLeading Price

TypeWorking Rolls

Forging Work Roll

Diameter2500Mm

Machining Length20000Mm

ProcessCasting

MaterialCarbon Steel

Heat TreatmentAnnealing

FeaturesHigh Strength, Wear Resistance, Customizable Size, Durable Material

Work Roll - Premium Quality Raw Material | Corrosion Resistant, Abrasion Resistant

MaterialSteel

HardnessHigh

DiameterCustomizable

LengthVariable

Surface FinishPolished

Heat TreatmentAvailable

H C & Company

Pune

Deals in:

Tool Tech Industries

Kolkata

Deals in:

Bajrang Tools And Rolls Pvt. Ltd.

Sonipat

Deals in:

View More

Forged Work Rolling Mill Roll - Color: Silver

Get Best Deal

Narrow Mill Work Roll - Color: Silver

Get Best Deal

Yashvanthi Fabricators

Bengaluru

Deals in:

Sree Ayyappa Curing And Fusing

Tirupur

Deals in:

Work Rolls: An Essential Equipment for Rolling Process

Work rolls are the essential part of rolling mill machines which directly come in contact with metal and help reduce its thickness during the rolling process. Also, the process not only reduces the thickness but also makes the surface smooth and cleans out the edges with no wrinkles at all. The outcome of the process is definite for one shape, the metal can be converted into bars, poles, tubes, bricks, or any other desired shape through the rolling process. Moreover, it also helps to enhance the tensile strength and yield strength of the metal being compressed.

Applications of Rolling Process Using Work Rolls

-

Automotive Industry

In the automotive industry, there are a diverse range of products that require rolling processes in manufacturing including axles, tubes, frames, and various others.

-

Construction

Frames are the essential parts of buildings and other large structures, which require a rolling process to give it a definite shape and enhance its tensile strength and other physical properties.

-

Aerospace

Rolling process is also used to manufacture several parts of aircrafts with strength and durability. As the parts go through the rolling process they are highly compressed by the rollers and have increased tensile strength.

-

Electronics

Electronics industry also uses a noticeable amount of metals for manufacturing durable and reliable products including circuit boards, wiring, compute chips, cabinets, and more.

-

Medical

Medical grade equipment is designed to be very reliable for saving patients in life threatening conditions. There is a wide range of metals used for manufacturing these equipment which go through a rolling process to enhance their physical properties.

-

Oil and Gas Industry

Oil and gas industry uses some of the highest grade metal products to store temperature sensitive items safely. Their metals go through a rolling process where work rolls compress them and enhance their strength.

-

Beverages

Beverage products are packed in various types of containers including cans. For manufacturing the best quality can containers, the metal sheets go through work rolls for smooth surfaces, enhanced strength, and clean edges.

Major Benefits of Rolling Process With Work Rolls

-

Consistent

Rolling machines can offer consistent thickness and quality throughout the process as long as metal sheets go through work rolls.

-

Smooth Finish

Through the rolling process metal sheets get a smooth finish with the help of uniform compression which eliminates the wrinkles.

-

Complex Shapes

By using the high compressing powder, the metal sheets can be designed to specific shapes including L, I, U channels, and rails.

-

Automatic Operations

Automatic rolling mill machines make the operations completely automatic from feeding metal sheets to creating desired shapes of products. With this there is no need for manual intervention which eliminates the chances of error.

-

Easy to Use

Automatic rolling mills are very easy to use, as the operator can feed data directly into the system and rest is taken care of by the machine.

Client Testimonials & Reviews

RajinderVig

SHARP EDGE

We are getting a very good response from tradeindia and their back-end team. They are very helpful and supportive. We have got a good number of quires that's very helpful for every business, tradeindia is a great platform for all start-up. We are thankful to tradeindia.com.

Harpreet Singh

INDIAN MACHINE TOOLS CORPORATION

The inquiry received through tradeindia.com are one of most relevant found on online business platforms. Their experience in handling business is rich and useful that becomes really beneficial for clients in some niche areas. Wish them all the best.

BalvantsinhZala

JAY SHAKTI MACHINE TOOLS

We are glad to associate ourself with tradeindia since 14 years. We are fully satisfied with the portal, We also suggest to others and our group to Associate with tradeindia. We had done business with many trade leads provided by this B2B portal. Thank you tradeindia.com.

Work Rolls Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

H C & Company Pune, India | 11 Years |

Tool Tech Industries Kolkata, India | 10 Years |

Bajrang Tools And Rolls Pvt. Ltd. Sonipat, India | 8 Years |

Perfect Roll Industries Ahmedabad, India | 2 Years |

Horizon Global Trade Ahmedabad, India | 1 Years |

Upcoming Tradeshows

CWIEME Shanghai 2026

Wed, 24 Jun, 2026 - Fri, 26 Jun, 2026

INDOMACH Jamshedpur 2026

Thu, 05 Feb, 2026 - Sun, 08 Feb, 2026

Asia Photonics Expo (APE 2026)

Wed, 04 Feb, 2026 - Fri, 06 Feb, 2026

IFF - India Fashion Forum 2026

Wed, 28 Jan, 2026 - Thu, 29 Jan, 2026

Plastic Packaging Printing Expo (P3) 2026

Fri, 10 Apr, 2026 - Mon, 13 Apr, 2026

STEEL CONSTRUCTION EXPO 2026

Thu, 26 Feb, 2026 - Sat, 28 Feb, 2026

Panacea - Natural Products Expo India 2026

Fri, 06 Mar, 2026 - Sun, 08 Mar, 2026

India Boat & Marine Show 2026

Thu, 29 Jan, 2026 - Sat, 31 Jan, 2026

Spectra Expo 2026

Wed, 06 May, 2026 - Fri, 08 May, 2026

Odisha Mining & Infrastructure International Expo 2026

Thu, 08 Jan, 2026 - Sun, 11 Jan, 2026

Popular Categories