- Tradeindia

- Machine Tools

- Backup Roll

Backup Roll

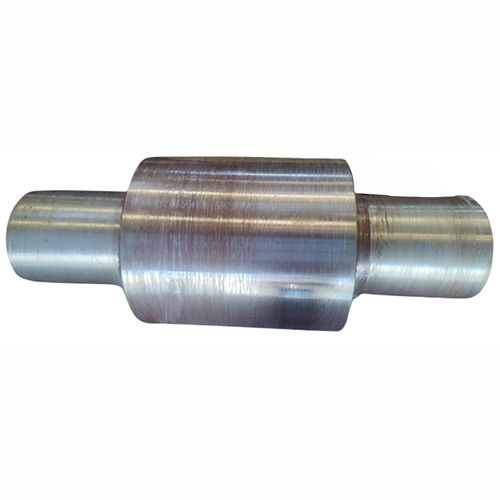

(52 products)Ss Backup Rolls - Color: Silver

MOQ1 Unit/Units

UsageIndustrial

MaterialSteel

SizeVarious

WeightDiffer as per size Kilograms (kg)

ColorSilver

FeatureHigh Quality

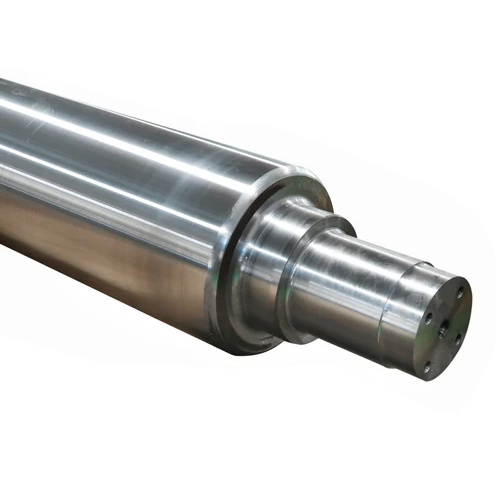

Work Roll and Backup Roll - EN31/High Carbon D2/D3 Steel, 450 mm Diameter x 4000 mm Length | High Performance, Durable Design, Prevents Roll Deflections

Price Trend: 20000 - 200000 INR/Piece

MOQ1 Piece/Pieces

Product TypeRolls

General UseSheet Rolling

MaterialSteel Alloy

TypeDrilling, Other, Turning

Surface TreatmentOther

FeatureSimple Control, High Performance, High Efficiency

Forged Steel Backup Work Roll - Color: Silver

Price: 65000 INR/Piece

MOQ1 Piece/Pieces

UsageIndustrial

ColorSilver

MaterialStainless steel

TechniqueHot rolled

FeatureDurable

View More

4Hi-6 Hi Backup Rolls - Color: Silver

Price : 50000.0 INR

Backup Roll - Color: Silver

Price : 60000 INR

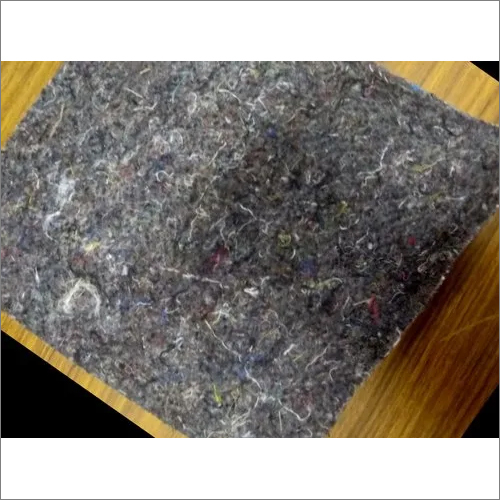

Grey Carpet Backing Roll - Non-Woven Polyester Fiber, 20m Length, Grey Color - Laminated Bond, Quick Dry, Printed Texture

Price: 200 INR/Meter

MOQ100 Meter

ColorBlack

PatternPrinted

FeatureQuick Dry

Fabric MaterialNon Woven Fabric

Bond TypeLaminated

TexturePrinted

Backup Roll - Automatic Grade: Automatic

Price: 30000 INR/Piece

MOQ1 Piece/Pieces

Applicationindustrial

Product Typebackup roll

Materialsteel

ComputerizedYes

Automatic GradeAutomatic

Control SystemPLC Control

backup rolls

MaterialSteel

DiameterVariable

LengthVariable

WeightVariable

Surface FinishPolished

HardnessHigh

View More

Back-Up Rolls

Price : 35000 INR

Lower Energy Consumption Top Quality Backup Rolls

FeatureHigh Performance, High Efficiency, Lower Energy Consumption

Backup Roll Choke

Bearing Size Range200-800 mm

MaterialSteel alloy

Surface FinishChrome plated

Roll DiameterVariable

Roll LengthVariable

UsageWork roll backup in mills, and other heavy industrial applications.

View More

Backup Roll Chokes

Get Best Deal

BACKUP ROLLS

MaterialSteel alloys, Stainless Steel

DiameterUp to 1050mm

LengthUp to 4000mm

Surface finishSmooth

HardnessVaries by alloy

ToleranceHigh precision

Stable Performance Industrial Backup Roll

Product TypeIndustrial Backup Roll

FeatureStable Performance

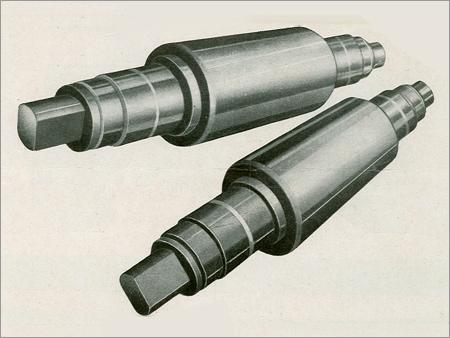

Forge Steel Backup Roll

MaterialSteel

DiameterVariable

WeightVariable

LengthVariable

FinishPolished

ToleranceHigh

Rolling Mill Backup Rolls

MaterialCast Steel

ConstructionMultilayer Sheet

MachineryAutomatic

DurabilityHigh

StrengthExcellent

LengthsDiverse

View More

Backup Rolls

Get Best Deal

Forged Back Up Rolls

Get Best Deal

Rolling Mill Backup Rolls Length: 8-24 Inch (In)

Get Best Deal

Forged Cold Mill Rolls

Get Best Deal

5 Hi Backup Rolls

Get Best Deal

Forged Cold Mill Rolls

Get Best Deal

FAQs Related to Backup Roll

Who are the top backup roll manufacturers in India?

- Ganesh Loco Components Private Ltd

- Tool Tech Industries

- Bajrang Tools And Rolls Pvt. Ltd.

- Perfect Roll Industries

- Horizon Global Trade

- Steel World

Which cities have the largest number of backup roll suppliers?

- Mumbai

- Bengaluru

- Delhi

- Pune

- Chennai

- Kolkata

- Hyderabad

- Ahmedabad

- Gurugram

- Ghaziabad

- Howrah

- Thane

- Sonipat

- Qingdao

- Xiangfan

What is the price range for backup roll offered by listed companies?

| Company Name | Currency | Product Name | Price |

|---|---|---|---|

| Rolls India | INR | Backup Roll | 30000 |

How many trusted sellers are available for backup roll?

- HORIZON GLOBAL TRADE

- TOOL TECH INDUSTRIES

- PERFECT ROLL INDUSTRIES

- GANESH LOCO COMPONENTS PRIVATE LTD

What is the minimum order quantity for backup roll?

Do listed companies have registration & certifications?

- KEC FORGINGS PVT. LTD.

- GANESH LOCO COMPONENTS PRIVATE LTD

What is the get latest price feature?

What types of payment methods are accepted by the backup roll suppliers?

Backup Rolls - Premium Quality Material, Unbeatable Performance Life | Ideal for Various Applications

MaterialSteel

Diameter10cm

Length20cm

Weight1kg

Surface finishSmooth

Hardness60HRC

View More

Best Selling Backup Rolls

Get Best Deal

Backup Roll

MaterialSteel

Diameter100Mm

Length200Mm

Weight5Kg

Surface FinishSmooth

Tolerance+/- 0.1Mm

View More

Backup Roll

Get Best Deal

Backup Roll

Get Best Deal

Plate Backup Roll

MaterialAlloy Steel

Diameter6-10 meters

LengthVariable

Surface FinishHigh Polish

Hardness60-65 HRC

UsageRolling thick plates for shipbuilding (generally thicker than 6mm)

Heavy Duty Backup Roll

MaterialSteel

DimensionsVaried

WeightVariable

FinishMachined

HardnessHigh

TolerancePrecise

Solid & Composite Backup rolls

MaterialSteel, Composite

Diameter Range50-200mm

Length Range1000-3000mm

Surface FinishRa 0.8µm

Hardness60-65 HRC

UsagePaper and textile industries, metal rolling mills, rubber processing

Backup Roll - Premium Quality, Durable Design | Versatile Use for All Your Needs

MaterialSteel Alloy

Diameter100-500mm

Length1000-3000mm

Surface FinishRa 0.8µm

Hardness55-65 HRC

UsagePaper/Textile processing

Bajrang Tools And Rolls Pvt. Ltd.

Sonipat

Deals in:

View More

Forged Backup Rolls - Color: Silver

Get Best Deal

Ganesh Loco Components Private Ltd

Jodhpur

Deals in:

Steel World

New Delhi

Deals in:

Aarav Steel Traders

Howrah

Deals in:

Noble Toolings & Hardware

Pune

Deals in:

Sri Jangir Machine Tools

Hyderabad

Deals in:

Dhiraj Metals

Delhi

Deals in:

R. A. Tool And Traders

Delhi

Deals in:

Vikas Machine Industries

Ahmedabad

Deals in:

Anandh Hardware

Chennai

Deals in:

Backup Roll to Maximize Efficiency and Performance

A backup roll is known for use in a rolling mill in large, heavy, mechanical parts. It functions for support with qualities like comprehensive strength, wear resistance, shock resistance, and long-lasting functional life. It supports the shape and thickness of the metal being processed. It helps to provide assurance regarding the shape of the metal being processed. It keeps the metal in the required shape and thickness of the entire rolling system. Backup rolls are made up of a mandrel, bearing sleeve, needle roller, seals, fasteners, and heat-resistant extreme-pressure grease. It helps to prevent bending and distortions in the metal being processed. These essential backup rolls are available in a variety of materials like forged steel, cast iron, high chromium steel, and alloy steel. Now, it’s available with various advances for durability and performance.

Types of Materials Used in Manufacturing the Backup Rolls

Backup rolls are manufactured with different types of material for the use of different industries and operations. All the material has different qualities required according to business product development. All the types of material are:

Forged Steel

Forged steel is used for manufacturing the backup rolls for delivering strong and durable performance. It has lots of benefits to manufacture backup rolls with it:

- Tough

- Uniform Surface Hardness

- Resistant to Fatigue

- High Degree of Structural Integrity

- Superior Chemical Uniformity

- No Shrinkage

- Reduced Cavities

- No Cold Pour Issues

- Reduction in Porosity

Cast Iron

Cast iron is a good option to manufacture the backup rolls. It’s less expensive and offers a good wear-resistance option for the industries. It shows durability but not as forged steel. It has many benefits like:

- Excellent Wear Resistance

- Good Thermal Cracking Resistance

- Act as a Natural Lubricant

- Able to Cast into Complex Shapes

- Less Expensive

High Chromium Steel

High chromium steel is used in manufacturing the backup rolls for different kinds of applications. It assists due to its useful features like:

- Excellent Wear Resistance

- High-Temperature Performance

- Durable

- Uniform Surface Finish

Alloy Steels

Alloy steel is useful for manufacturing the backup rolls. It’s prepared with elements like nickel, molybdenum, or vanadium for the increase of mechanical properties. It has different advantages like:

- Stronger and More Durable

- Resistant to Corrosion

- Easier to Weld

- Better Hardenability

- Better Machinability

Different Types of Backup Rolls

Backup rolls are available in different types for various industrial sector operations. It helps to build the product according to the requirements of the product manufacturing. All the types of backup rolls are used in different industries. The types of backup rolls are:

Solid Rolls

Solid rolls are a type of backup roll used in performing various industrial tasks. They are suitable for many industrial applications requiring solid, uniform material.

- Simple in design

- Homogeneous material

- Single-piece rolls

Composite Rolls

Composite backup rolls consist of a hard outer shell and a softer core. They're widely used in industries as rolling mills, levelers, and tension levelers. The mechanical part that bears the radial load generated when rolling or straightening the sheet has many uses.

- Optimize wear resistance

- Reduction in weight

- Better thermal performance

Textured Rolls

Textured backup rolls are used in special applications, such as roll texturing processes. They increase the grip with surface patterns and reduce slippage during rolling.

- Increase the grip

- Change internal structure

- Reduction in slippage

Sectional Rolls

Sectional rolls are used to support the roll operation with quality-assured development. It is suitable for both hot and cold rolling mills. It allows the manufacture of the quality and precision of rolled metal sheets, plates, and coils.

- Composed multiple sections

- Easy to maintain

- Worn part replacement

Features of Backup Roll

Backup roll is used in the various sectors to deal with the metal processing industries. It has many useful features to maintain the requirements of the product manufacturing. It has large solution aspects with its associated features. The features associated with the backup roll are:

Size and Weight

The backup roll must be according to the requirements of industrial applications. Industries require the heaviest and largest rolls to perform the operations.

Support

It is required to support the operation to prevent deflection in the performance of the task. It ensures the quality of the plate and strips in the rolling mill.

Hardness

Backup rolls are made up of different kinds of material used in manufacturing. The hardness of the backup roll directly depends upon the material. It must have high surface hardness and a deep hardened layer.

Strength and Toughness

Backup rolls must have good strength and toughness for long service life. The roll neck and roll body need strong material development. It ensures exceptional wear resistance with its strength and toughness.

Wear and Peel Resistance

Backup rolls require high wear and peeling structures to minimize the problem of any kind of wear and tear. It must have excellent hardness, a good surface finish, and a specified composition of alloy.

Anti-accident

Backup rolls are manufactured with anti-accident features for the prevention of any kind of accident. The materials used are made from high-strength materials like cast iron and high-quality steel.

Benefits of Backup Roll

Backup rolls are used in many industrial machinery to maintain the requirements of the business. It has many beneficial points to know like supporting features, durability, longer serving life, and better quality development of product. It maintains the business to manufacture the required and quality product. It has many benefits like:

Support

Backup roll allows the material to be rolled to prevent the problem of bending and distorting. It makes the product high quality and optimal for the next operation. It helps to support the whole manufacturing process with proper handling and rolling process.

Durability

Backup rolls help the production team to manufacture durable and strong product. It provides the product with special required features like high compressive strength, wear resistance, and shock resistance. It helps to deal with alternating bending stress for long periods of time.

Long Service Life

Backup rolls are used in manufacturing the cylindrical products. It rolls the sheets perfectly for the optimal requirements of the product. It is built with strong materials to provide proper operational facilities. Therefore, it has a strong service life and proper development of products.

High Quality

Backup rolls are manufactured with the best quality material to deal with every kind of material in various industries. It has a good holding capacity for every kind of sheet to get rolled. It is ideal to deal with every industry with high efficiency.

Application of Backup Roll

Backup rolls are part of rolling mills and other equipment. It is a mechanical part to support the operation of the roll and bears the load of rolling. It helps to straighten the sheets to provide required product development. It’s used for many industrial applications to develop the product with the requirement of rolling operation.

Precision and Uniformity

Backup rolls help the business to manufacture consistent quality products with the same material. It helps to meet the quality standards with precise and uniform product development. It has applications in the automobile and aerospace sectors for productive output.

Surface Finish

The use of a backup roll allows the development of the product with a good surface finish. It helps to minimize wrinkles, buckles, and any kind of imperfections. It provides a smooth surface finish with low minimal problem of wrinkle sheets.

Load-Bearing

Some products require a clear and proper surface with no bending and wrinkles. In that case, it requires straightening equipment to develop the product. It’s used in galvanizing lines, tin-plating lines, rewinding lines, and other process sections.

Shock Resistance

Backup rolls are used to provide products with feature shock resistance. It must be strong and can face high dynamic stresses. It provides strong featureful products to develop for the different sectors of the world.

Wear Resistance

Backup rolls are designed for the production of durable products resistant to wear and peeling. It must be productive and durable for long-life performance. It allows the business to maintain the productivity and efficiency of the business.

Client Testimonials & Reviews

RajinderVig

SHARP EDGE

We are getting a very good response from tradeindia and their back-end team. They are very helpful and supportive. We have got a good number of quires that's very helpful for every business, tradeindia is a great platform for all start-up. We are thankful to tradeindia.com.

Harpreet Singh

INDIAN MACHINE TOOLS CORPORATION

The inquiry received through tradeindia.com are one of most relevant found on online business platforms. Their experience in handling business is rich and useful that becomes really beneficial for clients in some niche areas. Wish them all the best.

BalvantsinhZala

JAY SHAKTI MACHINE TOOLS

We are glad to associate ourself with tradeindia since 14 years. We are fully satisfied with the portal, We also suggest to others and our group to Associate with tradeindia. We had done business with many trade leads provided by this B2B portal. Thank you tradeindia.com.

Backup Roll Price List

Product Name | Expected Price |

|---|---|

| Backup Roll | 30000 |

This Data was Last Updated on 2025-12-23

Backup Roll Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Ganesh Loco Components Private Ltd Jodhpur, India | 18 Years |

Tool Tech Industries Kolkata, India | 10 Years |

Bajrang Tools And Rolls Pvt. Ltd. Sonipat, India | 8 Years |

Perfect Roll Industries Ahmedabad, India | 2 Years |

Horizon Global Trade Ahmedabad, India | 1 Years |

Steel World New Delhi, India | 1 Years |

Upcoming Tradeshows

CWIEME Shanghai 2026

Wed, 24 Jun, 2026 - Fri, 26 Jun, 2026

INDOMACH Jamshedpur 2026

Thu, 05 Feb, 2026 - Sun, 08 Feb, 2026

Asia Photonics Expo (APE 2026)

Wed, 04 Feb, 2026 - Fri, 06 Feb, 2026

IFF - India Fashion Forum 2026

Wed, 28 Jan, 2026 - Thu, 29 Jan, 2026

Plastic Packaging Printing Expo (P3) 2026

Fri, 10 Apr, 2026 - Mon, 13 Apr, 2026

STEEL CONSTRUCTION EXPO 2026

Thu, 26 Feb, 2026 - Sat, 28 Feb, 2026

Panacea - Natural Products Expo India 2026

Fri, 06 Mar, 2026 - Sun, 08 Mar, 2026

India Boat & Marine Show 2026

Thu, 29 Jan, 2026 - Sat, 31 Jan, 2026

Spectra Expo 2026

Wed, 06 May, 2026 - Fri, 08 May, 2026

Odisha Mining & Infrastructure International Expo 2026

Thu, 08 Jan, 2026 - Sun, 11 Jan, 2026

Popular Categories