- Tradeindia

- Cranes

- Tower Crane

Tower Crane

(666 products)F 210 Nextgen Cranes - Application: Construction

MOQ1 Unit/Units

UsageIndustrial

ColorYellow

Crane Traveling Speed35 Km/hr

FeatureHydraulic Crane

ConditionNew

MaterialMild Steel

Action Construction Equipment Ltd.

Faridabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller10 Years

View More

TC 5540-T Tower Cranes

Get Best Deal

Acx 400 Crawler Cranes - Application: Construction

Get Best Deal

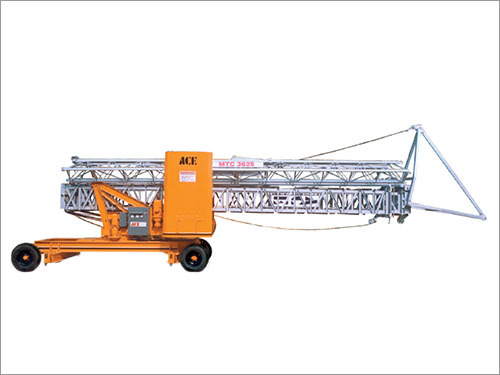

MTC 3625 Mobile Tower Crane

Get Best Deal

Tc 6552 Tower Cranes - Application: Storage Yard

Get Best Deal

MTC 2418 Mobile Tower Crane

Get Best Deal

Tc 7059 Tower Cranes - Color: Yellow Paint Coated

Get Best Deal

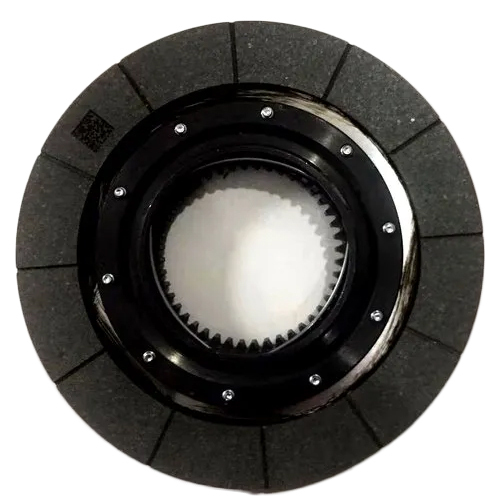

Black Anti Collision Device For Tower Cranes

Price: 3000 INR/Piece

MOQ1 , Piece/Pieces

UsageIndustrial

Power SupplyElectric

ColorBlack

Rated Voltage220 Volt (V)

SizeDifferent Sizes Available

WarrantyYes

Dynamic Crane Engineers Private Limited

Pune

Trusted Seller

Trusted Seller Super Premium

Super Premium5 Years

Super Premium

Super PremiumView More

Sli For Tower Cranes Usage: Industrial

Get Best Deal

Tower Cranes Sli Usage: Industrial

Get Best Deal

Eot Crane - Application: Warehouse

Price: 250000 INR/Unit

MOQAny Order Unit/Units

FeatureHydraulic Crane, Jib Crane, Truck Crane, Gantry Crane

Weight500 Pound (lb)

SizeDifferent Size Available

MaterialMetal

Crane TypeEot

ApplicationWarehouse, Factory, Railway

Shivay Engineering Works

Ahmedabad

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller5 Years

View More

Wall Mounted Jib Crane - Mild Steel, 5 to 10 Crane Capacity, 10 to 20 m Span, Electric Power Source, Max Height 20 to 40 Feet | New Condition

Price : 300000 INR

Mobile Crane - Color: Yellow

Price: 800000 INR/Unit

MOQ10 Unit/Units

ColorYellow

FeatureOther

SizeStandard

Product TypeMobile Crane

UsageIndustrial

ConditionNew

Shivam Construction Company And Earth Movers

Rohtak

Trusted Seller

Trusted Seller Super Seller

Super Seller3 Years

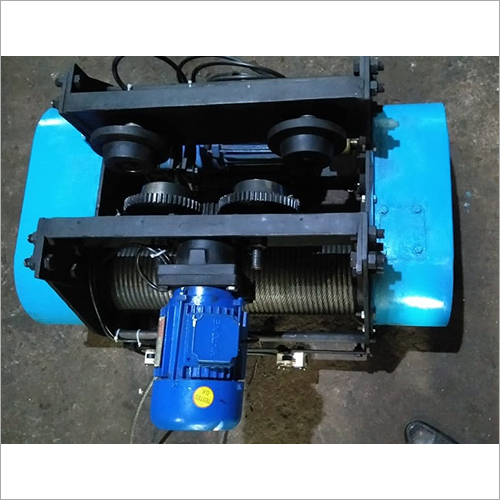

Vertical Crane - Iron Construction, Blue Finish | Remote Control Operation, Emergency Stop, Limit Switch

Price: 500000 INR/Unit

MOQ5 Unit/Units

Colorblue

Product Typecrane

FeatureOther

ConditionNew

UsageIndustrial

MaterialIron

Balaji Construction Machinery

Rajkot

Trusted Seller

Trusted Seller Super Seller

Super Seller14 Years

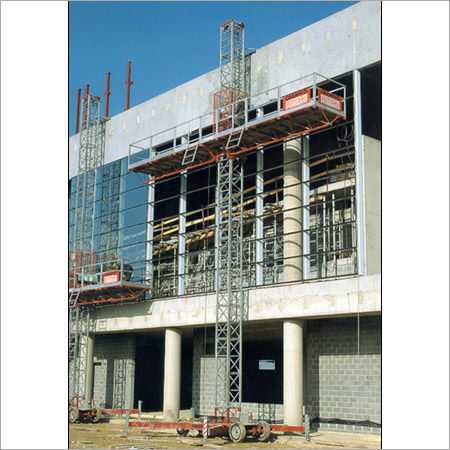

Tower Crane - Material: Mild Steel

MOQ1 Unit/Units

Product TypeTower Crane

FeatureHydraulic Crane

UsageMaterial Handling

ConditionNew

MaterialMild Steel

Eot Crane - Load Capacity: 10 Tonne

Price: 1 INR/Unit

MOQ1 Unit/Units

Electric HoistAs Per Requirement

Emergency StopYes

ConditionNew

Load Capacity10 Tonne

SpanLong Life

Operating ModeSemi Automatic

Fixed Tower Crane - Heavy-Duty Steel Frame, Versatile Lifting Capacity and Enhanced Stability

Price Trend: 350000.00 - 2.50 INR/Box

MOQ2 Box/Boxes

Supply Ability2 Per Day

Delivery Time1 Week

View More

Tower Crane Mast

Price : 50000 INR

Self Erecting Tower Crane

Price Trend : 100000.00 - 600000.00 INR

Ms Old Tower Crane Mast - Application: Construction

Price: 95000 INR/Piece

MOQ5 Piece/Pieces

ConditionNew

SizeStandard

ColorYellow

MaterialMS

ApplicationConstruction

Limit SwitchYes

Jagrit Construction Machinery

New Delhi

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

View More

Mini Tower Crane, Material: M.S

Get Best Deal

Tower Crane Spare Parts

Get Best Deal

Mini Tower Crane, Material: M.S

Get Best Deal

Durable 7 Feet Tower Crane

Price: 32500 INR/Unit

MOQ1 Unit/Units

UsageIndustrial

ColorYellow

SizeDifferent Available

Equipment TypeTower Crane

ConditionNew

Power SourceHydraulic

United Trading Company

Nagpur

Trusted Seller

Trusted Seller Premium Seller

Premium Seller3 Years

View More

Mini Electric Hoist Tower Crane Application: Construction

Price : 32500 INR

Mini Cranes, Power Source: Electric

Get Best Deal

Mini Construction Crane 3, Power Source: ELECTRIC

Get Best Deal

Electric Mini Lifting Crane, Power: Electric

Get Best Deal

Top Rated Products

FAQs Related to Tower Crane

- Get your degree.

- Acquiring Credentials

- Abide by the NCCCO's Substance Abuse Policy and Code of Ethics.

- Getting more practice

- Preparation is the key.

- Seek employment as a tower crane operator in your area.

- Be sure to renew your license as necessary.

E O T Cranes

Product DescriptionThese E O T Cranes are used in power house for maintenance purpose. Precision engineered, these cranes are available in a capacity of 125 ton and up to 35 meters span. Tested at each and every level of production, we ensure that E O T Cranes offered by us are robust in construction and highly reliab

Ruggedly Constructed Hydraulic Tower Crane

MOQ1 Unit/Units

FeatureHydraulic Crane

Product TypeTower Crane

ColorOrange, Red

MaterialMS, GI

ApplicationConstruction

Tower Crane Joystick - Frequency: 50 Hertz (Hz)

Price: 50000 INR/Piece

MOQ1 Piece/Pieces

Power SourceElectric

Product TypeTower Crane Joystick

Frequency50 Hertz (HZ)

PhaseThree Phase

Voltage380 Volt (v)

Usage & ApplicationsCranes

View More

Potain Tower Crane Hoist Brake Liner - Blade Material: Steel

Price : 6499 INR

48 Vac Tower Crane Hour Meter - Frequency: 50 Hertz (Hz)

Price : 900 INR

Sew Tower Crane Brake Disc - Color: Black

Price : 5000 INR

Tower Crane Anemometer - Material: Plastic

Price : 15500 INR

Tower Crane Concrete Bucket - Color: Yellow

Price : 35000 INR

3 Cup Tower Crane Type Anemometer - Material: Aluminium

Price : 9000 INR

MK Series Mobile Construction Crane - Metal, User-Friendly Features, Low Maintenance, Available in Various Colors | Versatile Tower and Mobile Crane Functionality

MaterialSteel

HeightVariable

CapacityVariable

ReachVariable

WeightVariable

Safety featuresMultiple

View More

Stainless Steel Self Erection Mobile Tower Crane

Get Best Deal

Yellow Mobile Tower Crane Counter Weight-Mtc3625

Price : 28500 INR

High Quality Fixed Tower Crane Pulleys for Reliable Performance

Price : 6500 INR

Mobile Tower Crane Hoisting Gear Box - Nord Make | Jib Crane Application, High Durability and Efficiency

Price : 4100 INR

Fixed Tower Crane Base Frame

Price : 450000 INR

Tower crane Jib Head

Price : 10000 INR

Golden Single Box Type Crane

Product DescriptionOwing to creativeness and adroitness of our team of ingenious professionals, we are affianced in manufacturing, exporting and supplying an exquisite array of Single Box Type Crane. Our Cranes are superior in quality. At International Cranes we manufacture Cranes according to customers need

View More

Mobile Floor Crane, Power Source: Hydraulic

Get Best Deal

Shop Floor Crane 2, Power Source: Hydraulic

Get Best Deal

Electric Crane, Power Source: Electric

Get Best Deal

Eot Single Beam Cranes, Power Source: Electric

Get Best Deal

32 Foot Dutch Head Crane

Dimensions32ft Height

MaterialMetal, Plastic

Rotation360 Degrees

Tilt360 Degrees

ControlRemote/Joystick

Features360 Rotation, Smooth Panning, Zoom Control, Height Adjustable, Remote Control, Easy Operation, Durable Design, Precise Control

Metal Jinwoo 750 Crane

MOQ1 Unit/Units

UsageIndustrial

ConditionNew

Product TypeJinwoo 750 Crane

MaterialMetal

WarrantyYes

Processing And Duty Service Cranes

Product DescriptionWe offers a wide range of highly functional Processing & Duty Service Cranes. These service cranes are highly durable, more beneficial and long lasting service provider to our customers. These crane is made with the latest technology & hi-speed performing engines to earn the keen attention of our cu

Niftylift Track Driven Machine

Product DescriptionThese Niftylift Track Driven Machines are driven from the platform while stowed they offer maximum traction on steep gradients and hydraulic outriggers allow fast setup even on rough terrain. Easy to use proportional controls make operation simple and features such as telescopic booms, fly-booms /

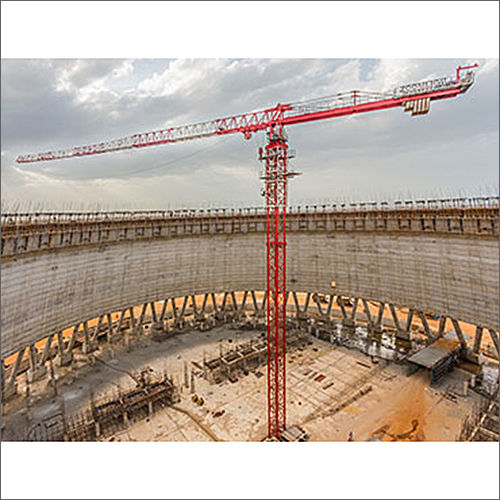

Tower Crane

Power SourceHydraulic

MaterialSteel

HeightVariable

Boom LengthVariable

CapacityVariable

Rotation360 Degrees

Shenzhen Juyi International Equipment Management Co., Ltd.

Shenzhen

Industrial Tower Crane Application: Construction

Price: 200000 INR/Unit

MOQ10 Unit/Units

ConditionNew

UsageIndustrial

MaterialIron

ApplicationConstruction

Control TypeCabin

Emergency StopYes

View More

Heavy Duty Flat Top Tower Cranes Application: Construction

Price : 150000 INR

Fixed Tower Crane Application: Construction

Price : 180000 INR

Monkey Hoist - 360 Rotation, 50M Rope Length, 45M Lifting Height, 500Kg Capacity | Hassle Free Performance, Remote Operations

Product TypeMonkey Lift

Rope Length50M

Lifting Height45M

Lifting Capacity500Kg

Rotation360

OperationRemote

Tower Crane

Price: 396000 INR/Piece

MOQ1 Piece/Pieces

ConditionNew

Product TypeTower Crane

ColorYellow

SizeAll

UsageIndustrial

MaterialMetal

Mast Section Tower Crane Trolley - Stainless Steel, Max Load Capacity 12 Ton, Silver Color | Hydraulic Crane Feature, Emergency Stop Enabled, New Condition

Price: 75000 INR/Unit

MOQ2 Unit/Units

Product TypeMast Section Tower Crane

ConditionNew

Usageindustrial

FeatureHydraulic Crane

Colorsliver

MaterialSS

Fixed Tower Cranes - Robust Steel Structure, Efficient Load Capacity, Nationwide Service Support

MaterialsSteel

ServiceNationwide

PricesAffordable

TypeFixed

RangeWide

FeaturesWide Reach, High Capacity, Nationwide Service, Affordable Price

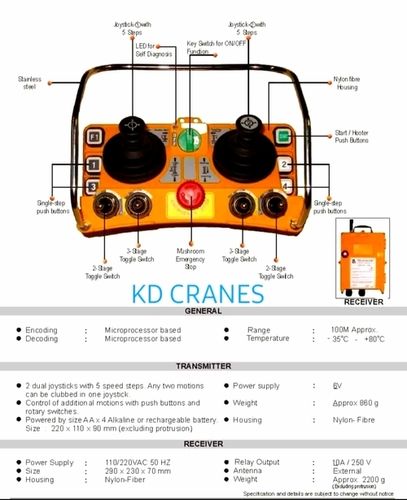

Tower Crane Wireless Radio Remote Control System Ingredients: Glutathione Ascorbic Acid

Price: 85000 INR/Box

MOQ1 Box/Boxes

Product DescriptionBrand name : KD Cranes \015\012Range : 100 MTR\015\012Voltage : 110V, 220V\015\012Condition : New\015\012Quality : Superior

Latest from Tower Crane

Client Testimonials & Reviews

Paresh Kareliya

GANESH ENGINEERING CO.

We are very thankful to Infocom Network Ltd. and its services to promote our product through Tradeindia.com on Internet. We get good support from their CRM and getting good Inquiries for Domestic as well internationally. We came to know of several portals but we choose Tradeindia.com for its services and different features we had been member since last 2 years and already subscribe for 2 more years in advance. from our Point of view we think Tradeindia.com is one of the best portals which we came to know from many years of experience of our business. We recommend Tradeindia.com as one of the best portal in online and off-line promotion for business activities. We wish Infocom Team and Specially their CRM Support Team for a great success in coming years and also wish that they will continue doing good work for long period.

Tower Crane Price List

Product Name | Expected Price |

|---|---|

| Tower Crane | 396000 |

| Tower Crane | 5000000 |

| Mobile Tower Crane | 1850000 |

| MS Old Tower Crane Mast | 95000 |

| Tower Crane | 60000 |

| Tower Crane | 1850000 |

| Mast Section Tower Crane | 75000 |

| mobile tower crane cage fork | 19500 |

| Mobile Tower crane | 70000 |

| Fixed Tower Crane | 150000 |

This Data was Last Updated on 2025-07-29

Tower Crane Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Yash Pal & Co. Kolkata, India | 19 Years |

Balaji Construction Machinery Rajkot, India | 14 Years |

Casmas Engineering Bhubaneswar, India | 11 Years |

Action Construction Equipment Ltd. Faridabad, India | 10 Years |

Alpha Crane Service Ballabgarh, India | 7 Years |

Dynamic Crane Engineers Private Limited Pune, India | 5 Years |

Shivay Engineering Works Ahmedabad, India | 5 Years |

Keshav Industries Ahmedabad, India | 4 Years |

Associated Hoists & Allieds Pvt. Ltd. Bengaluru, India | 4 Years |

Shivam Construction Company And Earth Movers Rohtak, India | 3 Years |

Upcoming Tradeshows

Autoserve 2025

Thu, 09 Oct, 2025 - Sat, 11 Oct, 2025

China (Guzhen) International Lighting Fair 2025

Wed, 22 Oct, 2025 - Sat, 25 Oct, 2025

Delhi Water Expo 2025

Thu, 21 Aug, 2025 - Sat, 23 Aug, 2025

INDUS-Tech Expo 2025

Fri, 19 Dec, 2025 - Mon, 22 Dec, 2025

Aesthetic Masterclass 2025

Thu, 28 Aug, 2025 - Fri, 29 Aug, 2025

Aquatech China 2025

Wed, 05 Nov, 2025 - Fri, 07 Nov, 2025

World Food India 2025

Thu, 25 Sep, 2025 - Sun, 28 Sep, 2025

WORLD OF CONCRETE INDIA 2025

Wed, 08 Oct, 2025 - Fri, 10 Oct, 2025

Water Expo Kochi 2025

Thu, 18 Sep, 2025 - Sat, 20 Sep, 2025

INTEXT Expo 2026

Fri, 16 Jan, 2026 - Mon, 19 Jan, 2026

Popular Categories