Tin Sheet

(107 products)JSW Steel Tin Sheet - Stainless Steel, Multiple Grades Available , Polished Silver Finish

MOQ100 Kilograms/Kilograms

Steel TypeStainless Steel

GradeMultiple Grades Available

Steel StandardAISI

SurfacePolished

ColorSilver

Jsw Steel Coated Products Limited

Vashind

Trusted Seller

Trusted Seller Super Premium

Super Premium1 Years

Tin Sheets - Steel, 100mm to 5000mm Length, 6mm to 1250mm Width, 0.14mm to 0.60mm Thickness | Excellent Lustre, Weldability, Corrosion Resistance, Paint Adhesion

Price: 210 INR/Kilograms

MOQ100 Kilograms/Kilograms

UsageAutomobile Industry, Sheet Metal Manufacturers, Pipes & Tubes, Industrial & Engineering Parts, White Good Manufactures, etc.

Width6mm To 1250mm Millimeter (mm)

MaterialSteel

Coil Thickness0.14 mm To 0.60mm Millimeter (mm)

Coil WeightAs Per Customer Requirement Kilograms (kg)

Coil Length100mm to 5000mm Millimeter (mm)

Titanium Sheet Grade 1 Ticp - Color: Silver-Gray

Price: 1250 INR/Kilograms

MOQ2000 Kilograms/Kilograms

Colorsilver-gray

Corrosion ResistantYes

Heat ResistanceYes

Product NameOther

Steel TypeTool Steel

Steel Product TypeSteel Structure

Tin Roofing Sheets

MaterialGalvanized steel

Thickness0.45 mm to 0.8 mm

Width750 mm to 1000 mm

Length2.4 m to 6 m

ColorBlue

FinishPre-painted

National Roofing Services

Mumbai

Premium Seller

Premium Seller3 Years

View More

Aluminum Alloy Tin Roofing Sheets

Price : 43000 INR

Plain Tin Sheets Application: Construction

Price: 85000 INR/Metric Ton

MOQ20 Metric Ton/Metric Tons

Product NameOther, Sheets

Steel TypeMild Steel

Steel Product TypeSteel Sheets

GradeIndustrial Grade

Thickness5-10 Millimeter (mm)

SurfacePolished

View More

Gc Sheet Tin Sheet Application: Construction

Price : 70000 INR

Galvanized Sheet Tin Mill Black Plate Coil

Price: 85 INR/Kilograms

MOQ5 Ton/Tons

MaterialGalvanized Sheet

TypeTin plate

TechniqueCold Rolled

View More

Tin Plate Sheet Application: Commercial

Price : 84.0 INR

Roofing Tin Sheets - Stainless Steel, Rectangular Size 15, Waterproof, Premium Quality, Plain Pattern, Available in Black, Red, Blue

MaterialStainless steel

Surface TreatmentGalvanised

GradePremium

ColorRed

Thickness0.45mm

Width1000mm

School Tin Slate

MaterialTin sheet

DimensionsVaried sizes

WeightLight

SurfaceSmooth

FramePrinted design

CornersReinforced

T1 T3 Tin Plate Sheet Grade: Industrial

MaterialTinplate

GradeT1 T3

Surface FinishPolished

ThicknessVariable

WidthVariable

LengthVariable

View More

Tin Plate Sheet For Food Cans Grade: Industrial

Price : 900 USD ($)

T2-T5 Misprint Tin Plate Sheet Grade: Industrial

Price : 900 USD ($)

Iron Coated Sheets - 10 ft Length, 3 ft Width | 2 mm Thickness, High Insulation, Multiple Colors, Weather-Resistant

Price: 1500 INR/Unit

MOQ200 Unit/Units

ColorComes in various colors

MaterialIron

ShapeRectangular

Length10 Foot (ft)

Width3 Foot (ft)

Thickness2 Millimeter (mm)

Tin Free Sheets

MaterialSteel

ThicknessVariable

WidthVariable

LengthVariable

Surface finishSmooth

WeightVariable

Gelatin Powder and gelatin sheets

Product DescriptionGelatin Powder and gelatin sheets

FAQs Related to Tin Sheet

Silver Stainless Steel Tin Roofing Sheet To Cover The Roof Of Your Home Or Anywhere

MaterialGalvanized steel

DimensionsCustomizable

ThicknessVariable

CoatingZinc

ProfileCorrugated

WeightPer square meter

Latona Byzantine Sheet

materialQuartz

thickness2-3 cm

water absorptionLow

densityHigh

finishPolished

hardnessDurable

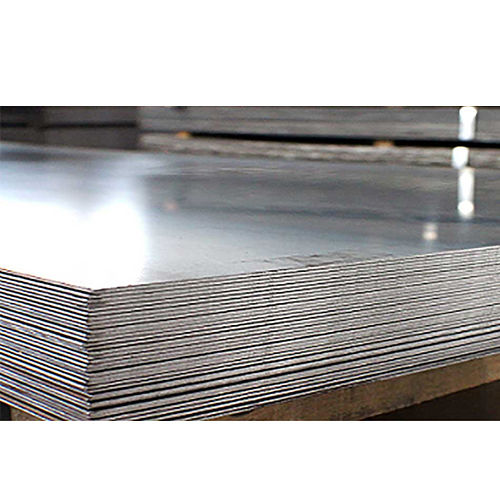

Tin Sheet - 0.15-0.5 mm Thickness, 750-1500 mm Width, Bright Tin Coating | Ideal for Food, Beverage, and Pet Food Packaging

MaterialTinplate

Thickness0.15 - 0.5 mm

Width750 - 1500 mm

Length1000 - 3000 mm

CoatingTin

Surface FinishBright

Solar Roof Top And Tin Sheet

MaterialPolycrystalline silicon

Dimensions1.65m x 1m x 0.05m

Power output250W

Voltage12V

Current10A

Warranty10 years

View More

Solar Rooftop

Price : 48500 INR

Tinned Sheets

MaterialTin-plated Steel

Thickness0.25mm - 1.5mm

Width500mm - 1500mm

Length1000m - 3000m

Coating Weight10g/m² - 20g/m²

Surface FinishBright

Tinfree Sheet - Steel, 0.15-0.5 mm Thickness, 1000-1500 mm Width | Corrosion Resistant, High Strength, Excellent Paintability, Cost Effective, Durable, Versatile

MaterialSteel

Surface TreatmentElectrolytic Chromic Acid

Thickness0.15 - 0.5 mm

Width1000 - 1500 mm

Length2000 - 6000 mm

Coating Weight5 - 20 g/m2

Galvanized Profile Sheets

MaterialGalvanized steel

Thickness0.5 mm - 2.0 mm

Width1000 mm - 1200 mm

Length2000 mm - 3000 mm

Surface finishSmooth

Weight10 kg/m² - 20 kg/m²

Grey Target Tin Sheet Fig 11 For Shooting Sports

ShapeSheet

FinishPolished

ColorGrey

ApplicationFor Shooting Sports

Coils Sheet Metal Tin Rolls - Tin Plated Steel, 0.25-1.5mm Thickness, Customizable Length | Durable, Corrosion Resistant, High Impact Strength

MaterialTin alloy

ThicknessVariable

WidthVariable

LengthVariable

PackagingRolls

FeaturesHigh strength, Corrosion resistant, Durable, Uniform thickness, Versatile, Cost-effective, On-time delivery

Tin Free Steel Pvc Coated Coils

MaterialTin free steel

CoatingPVC

Thickness0.12-1.2mm

Width600-1500mm

Length500-10000m

OriginItaly

Tin Patra Sheets

MaterialTinplate

Thickness0.21-0.5mm

WidthVariable

LengthVariable

CoatingTin coated

Surface finishSmooth

Available In Multicolor Heavy Duty Tin Sheet

MaterialTin plated steel

ThicknessVarious

WidthVarious

LengthVarious

Surface finishSmooth

GaugeVarious

Tin Candle Box - Premium Quality Metal, Various Shapes and Sizes | Custom Stylish Finish for Scented Candles

MaterialTin

DimensionsVarious

FinishMetallic

ShapeRound

Lid TypeSnap-on

WeightNA

Alluminium Coils

MaterialAluminum

ThicknessVarious

WidthVarious

LengthVarious

TemperVarious

FinishMill

Tinplate Sheet - SPCC, 0.18-0.45mm Thickness, 260-975mm Width, JIS G3303 Standard | Ideal for General and Aerosol Can Manufacturing

MaterialSPCC, MR

Thickness0.18-0.45mm

Width260-975mm

Tin coating2.8/2.8, 2.8/5.6, 5.6/5.6

TemperT2-T4 (BA)

StandardJIS G3303

View More

Tinplate - 0.18mm to 0.50mm Thickness | MR, SPCC Material, T2 - T4 Temper, Customizable Tin Coating

Get Best Deal

Tin Plates Coils

Get Best Deal

Tin Coils

Get Best Deal

Wrought Iron Steel Multi Color Tin Shades Fiber Shades For Roofing Length: 10 X 10 Foot (Ft)

MaterialSteel sheet

DimensionsVaried

CoatingZinc, Aluminum, Silicon

ColorBlue

Thickness0.5mm

Weight10kg/m2

What are tin sheets called?

A tin sheet is also called a tinplate. Tinplate is an anti-rust material made of steel sheets coated on one side with a thin coating of tin. Wrought iron was used as the backing metal until the introduction of less expensive milled steel.

Uses & Benefits of tin sheets

Types of tin sheets

1. Stainless Steel

Things to Consider Before Buying a tin sheets

1. Get TIS-approved metal sheets.

- Thicknesses between 0.23 and 0.28 millimeters are ideal for short-term roofing applications.

- Thinner roofing and walling projects (purlin spacing no more than 1.2 meters) are ideal for this thickness range, including houses, additions, garages, and awnings.

- Medium thickness roofing and general walling projects, such as those found in small or medium-sized companies, benefit from a thickness of 0.35 to 0.40 mm.

- Roofing projects with a thickness between 0.40 and 0.47 mm, such as moderately sized manufacturing facilities or office buildings, benefit the most from this range.

Tin Sheet Price List

This Data was Last Updated on 2025-12-24

Tin Sheet Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Jmt Steel-doshi Steel Group Mumbai, India | 12 Years |

Steel Overseas Jaipur, India | 8 Years |

Metal Vision Mumbai, India | 5 Years |

National Roofing Services Mumbai, India | 3 Years |

Indo Global Steel Mumbai, India | 2 Years |

Sonaar Infratech Private Limited Kashipur, India | 2 Years |

Jsw Steel Coated Products Limited Vashind, India | 1 Years |

Upcoming Tradeshows

CWIEME Shanghai 2026

Wed, 24 Jun, 2026 - Fri, 26 Jun, 2026

INDOMACH Jamshedpur 2026

Thu, 05 Feb, 2026 - Sun, 08 Feb, 2026

Asia Photonics Expo (APE 2026)

Wed, 04 Feb, 2026 - Fri, 06 Feb, 2026

IFF - India Fashion Forum 2026

Wed, 28 Jan, 2026 - Thu, 29 Jan, 2026

Plastic Packaging Printing Expo (P3) 2026

Fri, 10 Apr, 2026 - Mon, 13 Apr, 2026

STEEL CONSTRUCTION EXPO 2026

Thu, 26 Feb, 2026 - Sat, 28 Feb, 2026

Panacea - Natural Products Expo India 2026

Fri, 06 Mar, 2026 - Sun, 08 Mar, 2026

India Boat & Marine Show 2026

Thu, 29 Jan, 2026 - Sat, 31 Jan, 2026

Spectra Expo 2026

Wed, 06 May, 2026 - Fri, 08 May, 2026

Odisha Mining & Infrastructure International Expo 2026

Thu, 08 Jan, 2026 - Sun, 11 Jan, 2026

Popular Categories