- Tradeindia

- Prefabricated & Portable Buildings

- Prefabricated Structures

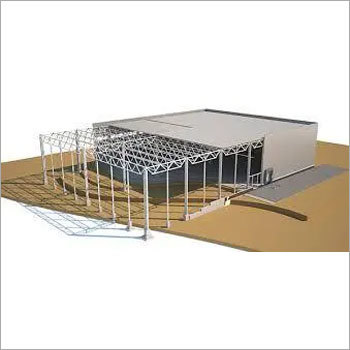

Prefabricated Structures

(815 products)Pre Fabricated Structures - Color: As Per Requirement

170 INR/Square Foot

MOQ50000 Square Foot/Square Foots

Window MaterialOther

Open StyleOther

ColorAs per Requirement

ConnectionAs per Design

InsulationOther

Door MaterialOther

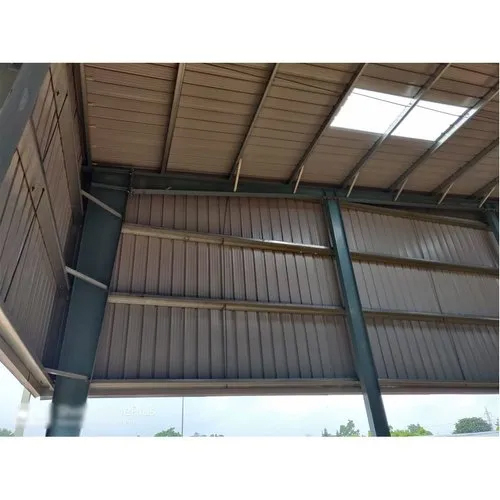

Pre Fabricated Structures - Color: White

90.0 INR/Kilograms

MOQ50000 Kilograms/Kilograms

MaterialSteel

Roof MaterialSteel

Colorwhite

UseWarehouse, Plant, Shop, Kiosk

View More

Heavy Steel Prefabricated Structure - Color: Galvanised

Price : 95.0 INR

Structural Prefabricated Shed - Color: Green

Price : 90.0 INR

Prefabricated Factory Building - Color: Galvanised

Price : 90.0 INR

Prefabricated Tubular Structure - Color: Galvanised

Price : 90.0 INR

All Colour Pre Engineered Building

Price: 350 INR/Square Foot

MOQ1 Square Foot/Square Foots

Door Materialsandwich Board

ColorAll colour

Window Materialsandwich Board

InsulationOther

Wall MaterialsSandwich Panel

Open StyleSliding

Prefabricated Structure

Price: 100000 INR/Container

MOQ1 Container/Containers

Wall MaterialsOther, Insulated Sandwich Panel

InsulationOther, Polyurethane / EPS / Rockwool

Open StyleOther, Sliding / Hinged

Door MaterialOther, Steel

ConnectionBolt Connection

ColorBlue, White, Custom

National Portable Cabin

Thane

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller Premium Seller

Premium Seller14 Years

Heavy Steel Prefabricated Structure - Color: Galvanised

Price: 95.0 INR/Kilograms

MOQ10000 Kilograms/Kilograms

MaterialSteel

Thickness Of Wall PanelCustomized Millimeter (mm)

ColorGalvanised,Color Coated

Reyna Infra Projects Llp

Mumbai

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller7 Years

View More

Structural Prefabricated Shed - Color: Green

Price : 90.0 INR

Pre Fabricated Structures - Color: White

Price : 90.0 INR

Prefabricated Factory Building - Color: Galvanised

Price : 90.0 INR

Prefabricated Tubular Structure - Color: Galvanised

Price : 90.0 INR

Light Weight Steel Structures - Steel Material, Custom Dimensions | Durable Design, Versatile Load Capacity, 25-Year Lifespan

Price: 250 INR/Square Foot

MOQ10000 Square Foot/Square Foots

Wall MaterialsSteel

Dimension (L*W*H)As per Requirement Inch (in)

ConnectionAs per Design

Life Span25 Yrs

MaterialSteel, Other

Roof MaterialSteel

Task Infracon Pvt. Ltd.

Faridabad

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller2 Years

Prefabricated Structure - Steel, Warehouse Dimensions, Blue Color | Long Life Span, Highly Durable, Easy Installation

Price: 1000 INR/Square Foot

MOQ50 Square Foot/Square Foots

Life SpanLong Life

ColorBlue

MaterialSteel

UseWarehouse

Eeco Portable Solutions Private Limited

Thane

Trusted Seller

Trusted Seller Super Premium

Super Premium Super Seller

Super Seller6 Years

View More

Prefabricated Structure

Get Best Deal

Prefabricated Structures - Color: As Per Requirement

Price: 400 INR/Square Foot

MOQ5000 Square Foot/Square Foots

Door MaterialPVC Window, sandwich Board, Other, Aluminum Window

Open StyleAutomatic

Wall MaterialsSteel, Sandwich Panel, Gypsum Board, PVC panel, Wooden, metal Sheet

InsulationGlass wool, Rock wool, PU, EPS, Other

ConnectionBolted

Window MaterialPVC Window, Aluminum Window, sandwich Board, Other

Padmadhara Structures Private Limited

Vadodara

Trusted Seller

Trusted Seller Super Premium

Super Premium4 Years

Prefabricated Structures - Door Material: Aluminum Window

Price: 200 INR/Square Meter

MOQ500 Square Meter/Square Meters

Door MaterialAluminum Window

MaterialSteel

Roof MaterialSteel

Window StyleOther

UseWarehouse

Relinfinite Projexive Private Limited

Vadodara

Trusted Seller

Trusted Seller Super Premium

Super Premium4 Years

Toilet Block - Metal and Fiber-Reinforced Panels, H: 2.5m x L: 3m x W: 1m, White Color, Insulated Single Metal Door, Durable Roof Options

Wall MaterialsOther, Fiber-reinforced panels with metal supports

Door MaterialOther, Metal

Life Span10-15 years

Dimension (L*W*H)Custom dimensions approximate H: 2.5m L: 3m W: 1m

Open StyleOther, Hinge door

InsulationOther, Basic wall insulation

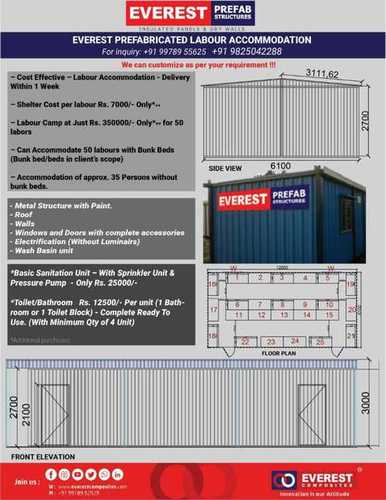

Everest Composites Pvt. Ltd.

Vadodara

Trusted Seller

Trusted Seller Super Seller

Super Seller18 Years

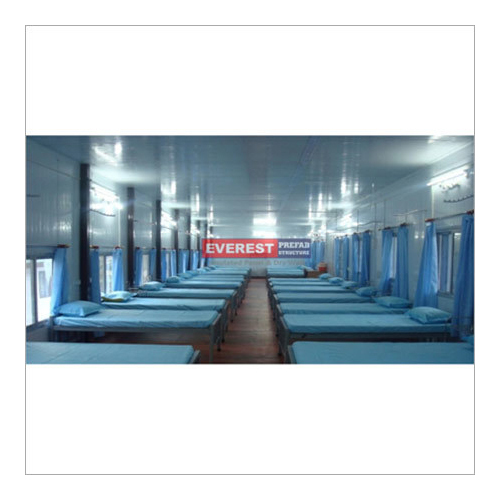

Prefab Accommodation Units - Color: White Blue

Price: 380.00 INR/Square Foot

MOQ1500 , Square Foot/Square Foots

ConnectionNails, bolts, and welding

Life SpanLonger lifespan

Open StyleSwing

ColorWhite Blue

MaterialSteel

Roof MaterialSteel

The Young Entrepreneurs

Jaipur

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller13 Years

View More

Prefabricated Office Structure - Color: White

Price : 750 INR

Prefabricated Structures - Color: White

Price : 450.00 INR

Office Cabins - Color: White

Price : 295000 INR

Prefabricated Roof Top Hostel - Color: White

Price: 950 INR/Square Foot

MOQ100 Square Foot/Square Foots

ColorWhite

MaterialSteel

Roof MaterialSteel

WindowOther

Window StyleOther

UseHouse

Pressmach Infrastructure Pvt Ltd.

Chennai

Trusted Seller

Trusted Seller Super Seller

Super Seller3 Years

View More

Prefabricated Structure - Color: White

Get Best Deal

Prefabricated Structure - Color: White And Yellow

Price : 1400 INR

Prefabricated E House Structure - Color: Yellow

Price : 1200 INR

Prefabricated Marketing Lounge Structure - Color: Gray

Price : 1900 INR

Office Cum Prefabricated Structure - Color: Brown

Price : 950 INR

Prefabricated Structures - Color: Grey

Price: 300.00 INR/Square Foot

MOQ8000 Square Foot/Square Foots

ColorGrey

MaterialSteel

Roof MaterialOther

WindowOther

Window StyleOther

UseOther

Unitech Structural Works

Kolkata

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller4 Years

View More

Prefabricated Steel Building Structure - Color: Grey

Price : 250 INR

Prefabricated Buildings - Color: Grey

Price : 300.00 INR

Prefabricated Steel Building Structure - Color: Grey

Price : 250 INR

Prefabricated Steel Structure - Steel Material, Modular Design, Easily Assembled | Ideal for Warehouse, House, Office Use, Low Maintenance, Durable

Price: 250 INR/Square Foot

MOQ5000 Square Foot/Square Foots

Roof MaterialSteel

Top Rated Products

Prefabricated Structure - Steel, Warehouse Dimensions, Blue Color | Long Life Span, Highly Durable, Easy Installation

Eeco Portable Solutions Private Limited

FAQs Related to Prefabricated Structures

Heavy Structural Fabrication Works

Price: 95 INR/Kilograms

MOQ500 Kilograms/Kilograms

FOB PortVADODARA

Payment TermsLetter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Western Union, Cash Advance (CA), Cash in Advance (CID)

Supply Ability100000 Per Month

Shree Sarjan Industries Pvt. Ltd.

Vadodara

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller10 Years

High Quality Prefabricated Buildings Structures

Price: 1500.0 INR/Square Foot

MOQ1 Square Foot/Square Foots

Product TypePrefabricated Buildings Structures

Main MaterialMetal

Surface TreatmentPainted

SizeAs Per Requirement

UsageIndustrial

FeatureHigh Quality

Prefabricated Metal Structure - Color: Multicolor

Price Trend: 200.00 - 350.00 INR/Square Foot

MOQ5000 , Square Foot/Square Foots

MaterialSteel

Roof MaterialSteel

Thickness Of Wall Panel10mm Micrometers (um)

Window StyleSliding Window

ColorMulticolor

UseWarehouse, Workshop

Multitech Infracon Private Limited

Kashipur

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller9 Years

Pvc Prefabricated Showroom Structure

Price: 390 INR/Square Foot

MOQ100 Square Foot/Square Foots

Floor MaterialPVC

UseWarehouse

Peb Surya Infra Steel Pvt. Ltd.

Pune

Trusted Seller

Trusted Seller Super Seller

Super Seller3 Years

View More

Insulated PUF Panel - 48 mm Thickness | Pre-Engineered, Economical Prefabricated Showroom Structure

Price : 1200 INR

Prefabricated Steel Structure - Durable Steel Material, 22 mm Wall Panels, Versatile Floor and Roof Steel

Price : 90 INR

Ms Prefabricated Shed Structure

Price : 350 INR

Ss Prefabricated Warehouse Structure

Price : 450 INR

Silver Supermarket Shopping Trolley

Price: 2850 INR/Unit

MOQ10 Piece/Pieces

ColorSilver

Wall MaterialsSteel

Open StyleFolding

MaterialSteel

Roof MaterialSteel

Floor Load50-100 Kilograms (kg)

Slotking India Storage System Private Limited

North Delhi

Trusted Seller

Trusted Seller Super Seller

Super Seller7 Years

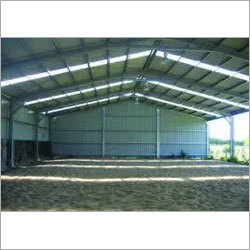

Durable Prefabricated Steel Shed - High-Grade Steel with Metal Sheet Roof, Glass Wool & Rock Wool Insulation | IS Welding Code Compliant Design

Price: 250 INR/Square Foot

MOQ10000 Square Foot/Square Foots

InsulationGlass wool, Rock wool

Wall Materialsmetal Sheet

Window MaterialOther

Open StyleOther

Door MaterialOther

Roof Materialmetal Sheet

Droit Steel Buildings Private Limited

Kolkata

Trusted Seller

Trusted Seller Super Seller

Super Seller11 Years

Multi Story Prefabricated Buildings - Color: Off White

Price: 250.0 INR/Square Foot

MOQ100 Square Foot/Square Foots, Square Foot/Square Foots, Square Foot/Square Foots

Window MaterialAluminum Window

Wall MaterialsSandwich Panel

Open StyleSwing

Dimension (L*W*H)Custom Foot (ft)

ColorOFF WHITE

InsulationPU

Prefabricated Industrial Structures

Price: 1000 INR/Square Foot

MOQ10000 Square Foot/Square Foots

Supply Ability300000 Per Month

Delivery Time2 Week

View More

Steel Structure Building - Stainless Steel , Prefabricated , Weather-Resistant and Corrosion-Free Solution for Commercial and Industrial Use

Price : 1000 INR

Prefabricated University Building Structure

Get Best Deal

Prefabricated Building Structure - Steel Framework, Customizable Modular Design, Quick Assembly Solutions

Get Best Deal

Prefabricated Mezzanine Floor Building Structure

Get Best Deal

Steel Structures - Robust Steel Frameworks | Durable, Versatile Designs for Industrial Applications

Price Trend : 50000.00 - 500000.00

Prefabricated Cold Storage Building Structure

Get Best Deal

Frangible Huts For Aerodromes - Color: Red

Price: 200000 INR/Square Meter

MOQ100 Square Meter/Square Meters

Door MaterialPVC Window

ColorRed

Roof MaterialAluminum sheet

Thickness Of Wall Panel20 Millimeter (mm)

Floor Materialcemented

Vahrk Enterprises Private Limited

Ghaziabad

Trusted Seller

Trusted Seller2 Years

Commercial Prefabricated Structure Service - Floor Material: Mild Steel

Price: 410 INR/Square Foot

MOQ1000 Square Foot/Square Foots

MaterialSteel

Roof MaterialSteel

Floor MaterialMild Steel

R. K. Engineering Works

Guwahati

Trusted Seller

Trusted Seller Premium Seller

Premium Seller6 Years

View More

Prefabricated Structure - Material: Iron

Price: 78 INR/Kilograms

MOQ1000 Kilograms/Kilograms

MaterialIron

Tile MaterialColor Steel Plate

Tile TypePlain Roof Tiles

TypePrefabricated Structure

PatternPlain

Thickness0.50 or 0.45 Millimeter (mm)

Cnd Engineering Pvt. Ltd.

Kolkata

Trusted Seller

Trusted Seller Premium Seller

Premium Seller8 Years

Prefabricated Structures - Roof Material: Steel

Price Trend: 800.00 - 1500.00 INR/Square Foot

MOQ1000 Square Foot/Square Foots

Wall MaterialsSteel

Door MaterialAluminum Window, Other

MaterialContainer, Foamed Tile, Asphalt Tile, Aluminum sheet, EPS, Rock wool, metal Sheet, Other, PU Panel

Roof MaterialSteel, Aluminum sheet, metal Sheet

View More

Prefab Factory Buildings

Price Trend : 5500.00 - 6500.00 INR

Steel Sheds - Mild Steel Warehouse/Factory Unit | Multicolour, Sliding Door, PVC Windows, 10-Year Lifespan, Metal Sheet Roof

Price : 6000 INR

Prefabricated Buildings - Steel Frame Structure, Modular Design, Customizable Layouts, Quick Assembly

Price Trend : 5500.00 - 6500.00 INR

Prefabricated Structures - Steel Construction, 20x08x8.6 Feet, White Color | Aluminum Sliding Windows, Water-Resistant Walls, Insulated Flooring

Price: 1000 INR/Foot

MOQ50 Foot/Feet

Dimension (L*W*H)20x08x8.6 Foot (ft)

InsulationGlass wool

Life Span8-10 Years

Open StyleVertical

Window MaterialAluminum Window

Door MaterialOther

Zigma Cabin Pvt. Ltd.

Thane

Trusted Seller

Trusted Seller Premium Seller

Premium Seller16 Years

Prefabricated Customize Structure - Color: Grey

MOQ100 Square Foot/Square Foots

Life SpanLong Life

Roof MaterialSteel

Thickness Of Wall PanelDifferent available Millimeter (mm)

ColorGrey

UseWarehouse, Workshop

6000Sq Feet IT Incubation Center

Price: 1950 INR/Square Foot

MOQ100000 Square Foot/Square Foots

Supply Ability10 Per Month

Delivery Time7 Days

Prefabricated Structure - Rust Resistant Metal | Long Lasting, Spacious Design for Warehouse, Workshop, Plant - White Finish

ColorWhite

UseWarehouse, Workshop, Plant

Latest from Prefabricated Structures

Prefabricated Structures

By:

Dharani Engineering & Co

22 Feet MS Prefabricated Structures

By:

Shree Krishna Pre-engineered Building

Popular Prefabricated Structures

Prefabricated Structures- An Introduction

The use of prefabricated technologies is not a new thing. In fact, prefab technologies have long shaped the construction sector of many advanced nations. Today, these technologies are embraced by many builders and realtors in developing countries too. Before we delve further, let us begin by understanding what prefabricated structures or prefabs are. Prefabs are buildings whose individual construction elements or components like floors, walls and roofs are made in a factory, a manufacturing plant or in a factory-like setting in advance, and only then transferred to the construction site or worksite for assembly. In certain cases, the components are also fully or partially assembled in the factory or plant before being transferred to the site. In industry, prefabs are made using a variety of prefabricated structure materials and are popularly known as Pre-Engineered Buildings (PEBs).

The Two Stages of Prefabrication

The construction of Pre-Engineered Buildings (PEBs) begins with the structure drawing. The structure design engineers after in-depth observation & analysis prepare the drawing and refer it to build the structure as per the relevant building codes and approved Quality Assurance Plan (QAP), while adhering to the client need & budget.

- First Stage: Components are manufactured in a factory, a manufacturing plant or in a factory-like setting, which is not the final location of construction.

- Second Stage: Components are shipped and the structure is erected in the final location of construction.

Advantages of Prefabrication- Technical, Economic & Sustainability Merits

Realty developers who are keen on adopting modern construction techniques to boost their works and compress delivery time-frames often favour prefabrication to the traditional ‘brick and mortar’ construction model while building permanent, semi-permanent or temporary facilities, including construction facilities, apartment blocks, healthcare camps, office spaces, evacuation centers, schools, colleges, etc. Time being money when it comes to building structures, prefabrication can often help in reducing the overall construction time and lend better resilience and quality to the building. To put simply, prefabrication is the best way for economizing time, effort, wages, and resources utilized in civil construction.

Prefabricated Structures can be considered advantageous for many good reasons, such as:

-

Precision: Such structures being made using self-supporting ready-made components reduce the need for formwork, shuttering and scaffolding, also giving factory precision to the components built. This is not the case with conventional construction methods.

-

Speed: Building anything from the ground up is time consuming. Fast turnaround is an advantage of prefab structures that are easier to erect and can be constructed in much less time.

-

Safety: Prefab structures made using durable materials can withstand the strongest of winds and earthquakes. As natural disasters continue to rise, prefabs are a smarter choice for constructing buildings, especially in disaster prone areas.

-

Quality: Prefabrication is always in demand as it minimizes the on-site congestion of sites, i.e., site disturbance, also helping one attain better quality control through factory assembly line setting. Besides, better thermal and sound insulation is witnessed in case of prefab structures.

-

Cost Efficiency: Any site where skilled labour, space and other resources are readily available can be transformed into a prefabrication site, which greatly reduces the total project cost. Cost also gets reduced as there is less wastage of construction material with prefabrication as compared to other traditional methods.

-

Technology: Latest fabrication technologies coupled with emerging CAD is expected to lend a further edge in the field of modular construction.

Apart from various cost and construction benefits, prefabricated structures also come with many environmental and social benefits. Especially, climate change that has intensified natural calamities in recent years have made prefabrication much preferable as an alternative method of construction because of its resiliency. Prefabs prove to be more affordable and durable than replacing damaged buildings in hostile post-disaster conditions. Therefore, home owners and construction companies of coastal areas that are more prone to hurricanes or tropical storms prefer these systems to minimize the effects of adverse climatic conditions on the infrastructural landscape and greatly improve community resilience in the process.

Environmental Impact- Prefab Versus Conventional Structures

Traditional construction methods used for erecting cast-in-situ buildings consume natural resources in excess, also leading to serious green-house gas emissions. Modern research also underlines that Prefab Versus Conventional Structures constructed at the same time and even in the same location show a marked difference in their carbon emission levels. Even when one considers the entire life cycle of buildings, there is minimal impact of prefabs on environmental damage as opposed to traditional cast-in-situ buildings.

Uses of Prefabrication

Apart from being utilized in the construction of large buildings, prefabrication is also used for building prefab concrete and steel sections in structures, mostly in cases where one building element needs to be repeated multiple times. Prefabrication comes handy in constructing apartment blocks and housing developments with repeated housing units, office blocks, factory buildings, storage houses, etc. Glass and steel sections are often prefabricated off site for use in the exteriors of huge structures and buildings. Prefabrication is also largely used for building mobile phone radio towers, aircrafts, etc.

Prefabricated Building Materials

With evolving technology, definition of modular construction too has attained a new meaning. Today, different materials go into the making of prefabs, which mostly are decided by the manufacturer. Manufacturers take note of specifications and budget of the customers before beginning any prefab project. Primarily, they use the following materials for prefabrication:

-

Steel: Modern construction relies on the versatility and strength of steel. Though its weight and rigidity make it a bit difficult to mould, steel can be shaped into any form with the right skills, technologies, and tools. Steel makes prefabs durable and fire-resistant. Besides, steel-framed modular structures are easier to assemble than the ones made of wood.

-

Wood: Wood being lighter than most materials is often chosen for prefab construction. Any framework can be crafted from a piece of wood. Sustainable species are usually preferred, which can even be reused and recycled into other materials. Medium-density fibreboard (MDF) and particle boards made of recycled wood are ideal for framing. Wood-frame structures made of durable wood are chosen to build structures that are expected to last thousands of years.

-

Concrete & Cement: Concrete plays a valuable role in prefab construction. Processes like manufacturing, moulding, drying, and curing steel-reinforced concrete or cement sections can be done in a factory setting where factors like ambient humidity and temperature can be easily regulated as per the need. Concrete used to engineer the core of a building can lend maximum support to the rest of the structure with its inherent strength.

Common Prefabricated Systems

Underlined below are the most common types of prefab systems used in the construction industry:

-

Panelized Wood Framing: Prefabricated Systems designed in the form of Panelized Wood Framing can make roof construction a safer, time saving and easier affair. In such cases, laminated timber is utilized for making long, sturdy pieces of frames, which are then covered either by plywood or board roof decks.

-

Sandwich Panels: For maximum structural stability, Sandwich Panels fabricated from thin facings of materials are often used. Facings made from materials like concrete, plywood, or stainless steel (SS) are used, which are then stuck to an insulating core. The core can be constructed of foam, rubber, paper or even textile (cloth).

-

Steel Framing: Prefab panels engineered from durable steel has become a prefabricated building material of choice for constructing commercial and residential structures.

-

Timber Framing: This type of framing though is not too common a practice used in India is widely used in building structures in other countries. Timber framings that are casted in factories or factory like settings are often used in building timber homes.

-

Concrete Systems: Concrete fragments engineered in the factory instead of being built on site can help in improving the look and feel of a building. The process also proves to be quite time saving.

-

Modular Systems: Here, the entire building structure is erected from factory-constructed assemblies and units that are hauled to the final construction site. These units made in various sizes and specifications are then connected to the prepared foundation.

Industry Applications

The lean construction mode of prefab is majorly utilized in the following areas:

-

Airports

-

Commercial Buildings

-

Engineering & Manufacturing

-

Infrastructure

-

Automobiles

-

Healthcare

-

Power

-

Textile

-

Retail

-

Warehousing & Logistics

Prefabricated Structure Specification

-

Foundation & Plinth

-

Structure

-

Flooring System

-

Walls

-

Roofing System

-

Windows & Doors

-

Mechanical, Engineering & Plumbing

Prefabricated Structure in India/ Prefabrication in India

Though many countries like Japan, USA, Europe, and Canada began transforming their infrastructural landscapes with prefabricated structures ages ago, prefabrication as a process gained ground in India only in 1950 when Hindustan Housing Factory was established with the aim of solving the housing problem created in India in the face of the refugee influx from West Pakistan. The company, the pioneer of prefab structure design and technology in India, was the first to throw light on the fact how prefab technology could generate instantaneous low-income housing solutions as compared to traditional brick-and-mortar structures. The target market which was earlier only the low-income group soon expanded and included hotels, up-market residences, commercial complexes, public utility buildings, etc.

Today, prefab structures, though popular in the civil construction sector of other countries, are still not a widely-adopted means of building structures in India. The method has not managed to attain the confidence of skeptical Indians, mainly because they are not completely aware of its benefits and simply see it as a low-income housing alternative. For many others, prefabrication conjures up images of unrealistic homes that come with unexpected risks. No wonder, the market of prefabricated buildings almost stands on the sidelines, accounting only 1% of the $100 Billion Real Estate Market of India.

The Takeaway

Prefabrication will soon be one of the finest examples of technological evolution, innovation & excellence.

With the rising population in India, many Indian construction companies, realtors, and builders have begun responding smartly to the need of the hour by gravitating towards prefabrication when taking construction projects related to building housing societies, malls, hospitals, schools, etc. The mission is to break the confines of traditional building methods, keep pace with the global construction industry, embrace innovative construction materials and construction techniques, and offer revolutionary prefab building solutions with many added benefits. According to many recent reports, the next decade will see prefab construction taking a giant leap in India supported by several reforms initiated & announced by the Indian Government and we all are more than optimistic.

FAQs: Prefabricated Structures

Q. What is a PEB or a Pre-Engineered Building?

Ans: A PEB or a Pre-Engineered Building is a building whose structural elements are constructed off-site as per a predetermined structural drawing. The elements are then transported to the final location of construction for installation.

Q. What is the average time taken to construct a prefab?

Ans: The construction procedure of a prefab is quick, and the time taken for construction is almost 30 to 50 percent less than a conventional brick and mortar structure.

Q. Are steel framed prefab structures safe in lightning?

Ans: Yes, steel framed prefabs are safe in lightning and score high in terms of protection.

Q. What is the price of a prefab building or structure?

Ans: The price of a prefab may vary depending on the building design, application, aesthetics, and technical configuration.

Q. What is the longevity of a prefabricated structure?

Ans: Prefabs are designed to last for years. The exact life of a prefab depends on its technical specifications.

Explore Prefabricated Structures at Tradeindia

Tradeindia networks with specialist providers of Prefabricated Structures who contribute significantly to India’s infrastructural development and whose products are a blend of innovative ideas and cost-effective construction technologies. All the players have track records of providing innovative yet affordable housing options and keeping up with tight deadlines.

Client Testimonials & Reviews

RajeshPoddar

GLOBAL TENSILE STRUCTURE

We are associated with tradeindia from last 1 year and this platform helped us to improve and grow our business, branding and promotion. I am getting good inquires and I expect the same in the future.

AnilKumar

ARIES PRE FAB PVT. LTD.

I am member of tradeindia since last 5 to 6 years and am very happy with tradeindia service. I am fully satisfied with tradeindia service due to good promotion, good inquiries and good visibility.

DilipSharma

TRADEWILL INTERIORS

We get good business through tradeindia.com. Tradeindia.com is helping our company to introduce our products in Indian and Global market. We wish all the best to tradeindia team and hope for your continuous support in the coming years.

Shaveen Mehta

MULTI DECOR INDIA PVT. LTD.

We are satisfied with the services of tradeindia as it has been more than 6 years with them and they have provided us full support whenever we needed. Hoping for the best service from tradeindia in future.

K.Azeez

UNIQUE ENGINEERING WORKS

We are the member of tradeindia for past six years. We felt very happy for same and proudly say investing money at tradeindia in use. Kindly support and give me best services in future also.

Prefabricated Structures Price List

This Data was Last Updated on 2025-12-18

Prefabricated Structures Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Everest Composites Pvt. Ltd. Vadodara, India | 18 Years |

Zigma Cabin Pvt. Ltd. Thane, India | 16 Years |

National Portable Cabin Thane, India | 14 Years |

Seltech Metal Building & Roofing Solution Greater Noida, India | 14 Years |

The Young Entrepreneurs Jaipur, India | 13 Years |

Dhaval Technologies Llp Pune, India | 13 Years |

Santani Steel Vadodara, India | 11 Years |

Droit Steel Buildings Private Limited Kolkata, India | 11 Years |

Balaji Roofing Vadodara, India | 10 Years |

Shree Sarjan Industries Pvt. Ltd. Vadodara, India | 10 Years |

Upcoming Tradeshows

CWIEME Shanghai 2026

Wed, 24 Jun, 2026 - Fri, 26 Jun, 2026

INDOMACH Jamshedpur 2026

Thu, 05 Feb, 2026 - Sun, 08 Feb, 2026

Asia Photonics Expo (APE 2026)

Wed, 04 Feb, 2026 - Fri, 06 Feb, 2026

IFF - India Fashion Forum 2026

Wed, 28 Jan, 2026 - Thu, 29 Jan, 2026

INTERNATIONAL CAFE AND BEVERAGE SHOW (ICBS) 2026

Thu, 07 May, 2026 - Sat, 09 May, 2026

AutoTechnika 2026

Fri, 05 Jun, 2026 - Sun, 07 Jun, 2026

Wall Floor & Ceiling Expo 2026

Mon, 13 Apr, 2026 - Wed, 15 Apr, 2026

Power On 2026

Fri, 23 Jan, 2026 - Sun, 25 Jan, 2026

AGROWORLD EXPO 2026

Fri, 20 Feb, 2026 - Mon, 23 Feb, 2026

Odisha Mining & Infrastructure International Expo 2026

Thu, 08 Jan, 2026 - Sun, 11 Jan, 2026

Popular Categories