- Tradeindia

- Pollution Control & Monitoring Equipment

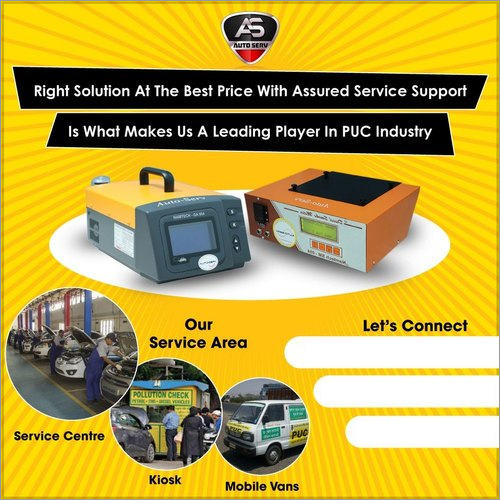

- Pollution Check Equipment

Pollution Check Equipment

(49 products)Vehicle Pollution Check Machine

Price: 110000 INR/Unit

MOQ01 Unit/Units

Product TypeVehicle Pollution Check Machine

Samvit Garage Equipments

Gurugram

Trusted Seller

Trusted Seller18 Years

Premium Seller

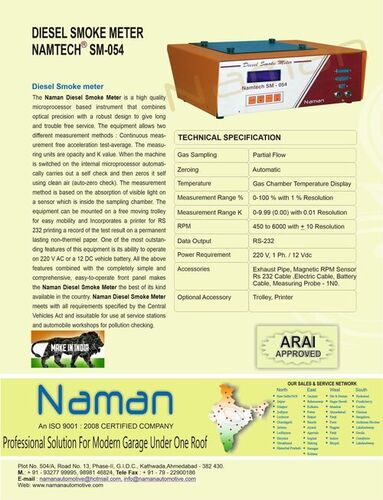

Premium SellerMetal Industrial Air Pollution Monitoring Equipment

Price: 1200 INR/Unit

MOQ1 Unit/Units

Product TypeIndustrial Air Pollution Monitoring Equipment

MaterialMetal

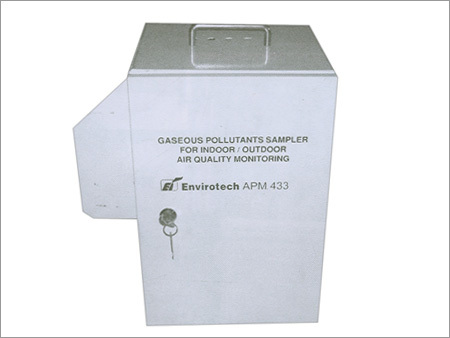

Steel Gaseous Pollutant Sampler

Price: 37000.00 INR/Piece

MOQ1 Piece/Pieces

Product TypePolluant Smapler

MaterialSteel

Cooling SystemAir Cooling

Voltage220 Volt (v)

Pollution Checking Machine Petrol/ LPG/CNG

Price: 150000.00 INR/Unit

MOQ1 Unit/Units

Product DescriptionPollution Checking Machine Petrol/ LPG/CNG

Air Quality Monitoring Instruments

Price: 120000 INR/Piece

MOQ1 Piece/Pieces

Payment TermsCash Against Delivery (CAD), Cash on Delivery (COD), Telegraphic Transfer (T/T), Western Union, Paypal, Others, Cheque

Supply Ability10 Per Day

Delivery Time5 Days

Pollution Check Machine - Material: Mild Steel

Price: 120000.0 INR/Unit

MOQ1 Unit/Units

UsagePollution Checking

Power SupplyElectric

Voltage220V Volt (v)

MaterialMild Steel

Control ModeAutomatic

Remote Optional Stainless Steel Diesel Machine

Price: 120000 INR/Piece

MOQ1 Piece/Pieces

Product TypeRemote Optional Stainless Steel Diesel Machine

MaterialStainless Steel

Aerosmart Gas Analyzer

Price: 160000 INR/Piece

MOQ1 Piece/Pieces

ColorBLUE & WHITE

Product TypePUC

MaterialMILD STEEL

Voltage220 Volt (v)

Warranty1 YEAR

220 Voltage Stainless Steel Pollution Check Equipment Noise Level: 2 Db

Price: 140000 INR/Piece

MOQ1 Piece/Pieces

Product TypePollution Check Equipment

MaterialStainless Steel.

Noise Level2 db

Processing Time15 Seconds

Voltage220 Volt (v)

Weight10 Kilograms (kg)

Air Pollution Checking Machine

Payment TermsDelivery Point (DP), Days after Acceptance (DA), Cheque

Supply AbilityAs per demand Per Day

Delivery Time1 Week

Combined PUC Analyzer

Price: 270000.00 INR/Piece

MOQ1 Piece/Pieces, Piece/Pieces, Piece/Pieces

Product TypeCombined PUC Machine

MaterialMS

Voltage220 Volt (v)

Top Rated Products

FAQs Related to Pollution Check Equipment

The common pollutants are particulate matter, carbon dioxide, carbon monoxide, oxides of nitrogen, sulphur as well as unburnt hydrocarbons.

Contamination Checking Kit In Ahmedabad Trident Engineering, Application: Oil Testing

Product DescriptionContamination Checking Kit In Ahmedabad Trident Engineering

PUC Pollution Testing Machine

Price: 139000 INR/Piece

MOQ50 Piece/Pieces

Product TypePollution Testing Machine

High-Efficiency Pollution Testing Machine Voltage: 220 Volt (V)

Price: 250000 INR/Unit

MOQ1 Unit/Units

Product TypeHigh-efficiency Pollution Testing Machine

Voltage220 Volt (v)

Vehicle Pollution Testing Machines

Payment TermsCash in Advance (CID)

Delivery Timewithin 1 Week

Packaging Detailsas per order

Air Pollution Monitoring Instrument

Product DescriptionRiding on unfathomable volumes of industrial expertise, we are engaged in manufacturing, importing, exporting and supplying a superior collection of Air Pollution Monitoring Instrument in New Delhi, Delhi, India. Our offered instruments due to their reliable capability in providing accurate results

Metal Petrol Vehicle Pollution Check Machine With Self Diagonstic Facilty

Price Trend: 120000.00 - 280000.00/Piece

MOQ01 Piece/Pieces

Product TypePollution Check Machine

MaterialMetal

Voltage230 Volt (v)

Primium Pollution Check Machine

Product TypePollution Check Machine, Motorcycle Helmet

MaterialPrimium

Pollution Monitoring Van

Product DescriptionWith the continuous help of our professional experts, we present a huge range of pollution monitoring van to our customers. These van are develop using high grade raw material and precise engineering. Our vehicle are tested on various parameters to assure the quality. We provides these monitoring va

Modern Pollution Testing Machine

Payment TermsCash in Advance (CID)

Delivery Timewithin 1 Week

Packaging Detailsas per oder

Pollution Checking Machine - Compact Design with 8 Bit Microprocessors | Smart LCD Display, Automatic Calibration, AC/DC Operation, Low Power Consumption

Product DescriptionFeatures of Pollution Checking Machine: Elegant and Smart appearance Indiginsied Compact Product A state of the Art technology Outstanding accuracy, stability and durability Response time of less than 10 seconds Standby for low power consumption when not in use 8 Bit - Microprocessors control Graphi

Model Ec2-10 Waterproof Conductivity Testing Pen

Payment TermsCash on Delivery (COD), Cash Advance (CA), Cash Against Delivery (CAD), Cheque

Main Domestic MarketAll India

Pollution Checking Device

Product DescriptionWith the assistance of our well expert team of our company, we are engaged in distributing and supplying a huge series of Pollution Checking Device in Bengaluru, Karnataka, India. Offered range of Pollution Checking Device is manufactured using best grade raw material at manufacturer's end. One can

Air Pollution Monitoring Instruments

Product DescriptionKnowing us as a reputed firm, we are engaged in manufacturing and supplying a wide range of Air Pollution Monitoring Instruments in Ahmedabad, Gujarat, India. Our offered product is manufactured employing optimum grade raw material. The raw material source from trusted ad reliable suppliers of the m

Metal I3Sys Pollution Testing Machine

Price: 270000 INR/Piece

MOQ1 Piece/Pieces

Product TypePollution Testing Machine

MaterialMetal

More details...

Vishwanjali Technology Pvt Ltd.

Pune

Trusted Seller

Trusted Seller3 Years

Premium Seller

Premium SellerLatest from Pollution Check Equipment

Explore More Cities

Client Testimonials & Reviews

AshishVerma

Enviro Instruments

TradeIndia has provided a great platform to me. It has given me a wide opportunity to sell my products in different parts of the world.A

GauravChauhan

RONAK INDUSTRIES

We are a member of tradeindia since last 4 years. We have fully satisfied for services provided by them to us and tradeindia is an excellent Portal and B2B services where buyers and supplier interact together.

Pollution Check Equipment Price List

This Data was Last Updated on 2025-03-03

Pollution Check Equipment Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Envirotech Instruments Pvt Ltd New Delhi, India | 22 Years |

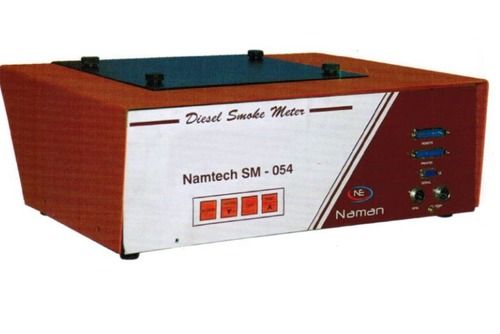

Naman Automotive Solutions Ahmedabad, India | 19 Years |

Samvit Garage Equipments Gurugram, India | 18 Years |

Greentech Instruments New Delhi, India | 9 Years |

Star Flow Technologies Faridabad, India | 3 Years |

Vishwanjali Technology Pvt Ltd. Pune, India | 3 Years |

Aarya Automative Solutions Mohali, India | 2 Years |

Axis Tools And Equipements Agra, India | 2 Years |

Upcoming Tradeshows

CWIEME Shanghai 2025

Wed, 25 Jun, 2025 - Fri, 27 Jun, 2025

Bakery and Commercial Kitchen Equipment 2025

Thu, 12 Jun, 2025 - Sat, 14 Jun, 2025

Vietnam Sport Show 2025

Thu, 14 Aug, 2025 - Sat, 16 Aug, 2025

Water Expo Bhubaneswar 2025

Thu, 10 Apr, 2025 - Sat, 12 Apr, 2025

Singapore International Jewelry Expo 2025

Thu, 10 Jul, 2025 - Sun, 13 Jul, 2025

Printing South China 2025

Tue, 04 Mar, 2025 - Thu, 06 Mar, 2025

CHINA INTERNATIONAL FURNITURE FAIR 2025

Tue, 18 Mar, 2025 - Fri, 21 Mar, 2025

Food & Bakery Expo 2025

Fri, 29 Aug, 2025 - Sun, 31 Aug, 2025

MachAuto 2025

Fri, 25 Jul, 2025 - Mon, 28 Jul, 2025

PU TECH 2025

Wed, 09 Apr, 2025 - Fri, 11 Apr, 2025

Popular Categories