- Tradeindia

- Piston & Piston Rings

- Piston Ring Sets

Piston Ring Sets

(491 products)O Ring - Parker Authorized Dealer | Premium Quality, All Sizes Available, Versatile Application

Price: 65000 INR/Piece

MOQ1 Piece/Pieces

EfficiencyHigh Sealing Efficiency

Mounting TypeOther, Groove Mounted

Sealing TypeOther, Axial or Radial Sealing

FeaturesAbrasion resistant, Chemically inert, High elasticity, Resistant to oil and solvents

ApplicationHydraulic systems, Pneumatic equipment, Automotive, Chemical processing, Food machinery

AccessoriesAvailable in O-ring Kits, Lubricants for installation

Piston Ring Set - Steel, Export Worthy Packaging | High-Quality Replacement for Japanese Vehicles, Immediate Delivery

Price: 4500.0 INR/Set

MOQ1 Set/Sets

Cooling SystemPiston Ring Set

Product TypeTruck Engine Parts

Parts NameOther

MaterialSteel

ApplicationAutomobile

SizeAs per Specifications

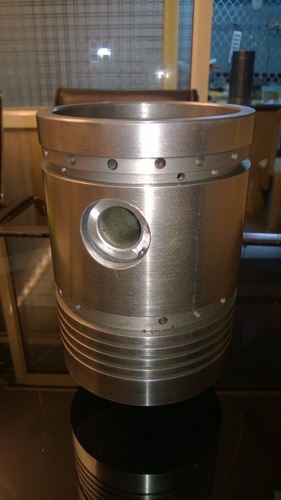

Marine Piston Ring

Price: 1000.00 INR/Unit

MOQ10 Unit/Units

Working PressureWithstands up to 400 bar (typical for large marine engines)

Equipment TypeMarine Piston Ring

CapacityEndures High RPM and Load

Operating TemperatureUp to 350AdegC

Product TypePiston Ring

TypeOthers, Marine Engine Spare Part

Shri Ram Engineers

Rajkot

Trusted Seller

Trusted Seller Premium Seller

Premium Seller16 Years

View More

MTU 362 Piston Ring

Price : 1000.00 INR

MAK 551 Piston Ring Set

Get Best Deal

MTU Piston Ring Set for Marine Engine

Get Best Deal

Piston Ring Set for Daihatsu DG Engine DV32L

Price : 1000.00 INR

Piston Ring Set for Marine Engine

Get Best Deal

MTU 362 Piston Ring Sets

Get Best Deal

Cummins Engine Piston Rings Application: Commercial

MOQ10 Unit/Units

Parts NameEngine Mounts

MaterialAluminum, Rubber

ApplicationCommercial

SizeCustomized

WarrantyYes

Forbes Marshall Piston Valve Ring - Stainless Steel Reinforced Graphite, Size: 15mm to 250mm, Class: 150 & 300, Provides Tightness & Durability Across Various Media

Price: 6000 INR/Unit

MOQ1 Number

MaterialForged Carbon Steel/ Stainless Steel / Alloy Steel

Valve TypeForged/Bar Stock, Bolted Bonnet

FeaturesBlow-out proof design, Zero gland leakage, Firesafe, Long lifecycle, In-line maintainable

Control SystemManual Operation

Connection TypeFlanged / Screwed / Socket Welded

Valve Size15 mm to 200 mm

Flowbiz Exports Private Limited

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller3 Years

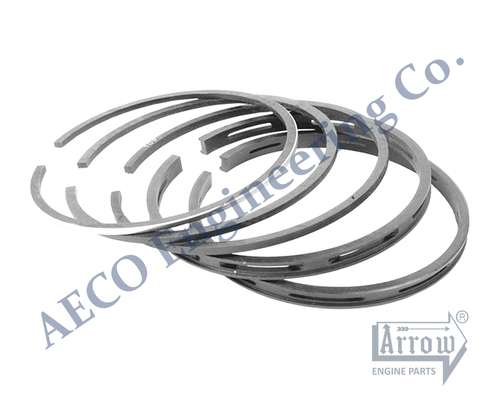

Piston Ring Set - Steel Alloy, Customized Size, Silver, High Load Bearing, Low Noise, Oil Lubricated, Chrome Plated, -20°C to 200°C, 50,000 km Life

SizeStandard Or Customized

FinishSmooth

Part TypeEngine Component

Temperature Range-20Adegc To 200Adegc

Working Life50000 Km

Connecting TypeFriction Fit

View More

HYD. LIFT PISTON BACKUP WASHER & O RING SET

Get Best Deal

Tractor Piston Ring Set

Get Best Deal

Km - Piston Ring 40-5 - Color: Dark Grey

MOQ100 Piece/Pieces

MaterialMetal

FeaturesGood Quality, Easy to Install, Long Life

UsageIndustrial

ShapeRound

SizeStandard

Product TypeKM - PISTON RING

Piston Range G. 1150

Price: 775 INR/Piece

MOQ1 Piece/Pieces

Temperature Range-20AdegC to +120AdegC

ColorSilver Grey

Product TypePISTON RANGE

Weight1.2 Kilograms

MaterialAluminium Alloy

Model NoG. 1150

Piston Rings - Cast Iron Material | High-Quality Gas Compression Sealing for Compressors

Price Trend: 30000.00 - 100000.00 INR/Unit

MOQ1 Unit/Units

UsageCOMPRESSOR

MaterialCAST IRON

Product TypePISTON RING

Real Air Technologies Pvt. Ltd.

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller5 Years

T/C Piston Ring Set Perkins 1103A-33,1104 (Std)

Price Trend: 500.00 - 1000.00 INR/Piece

MOQ50 Piece/Pieces

MaterialIron

View More

Iron T/C Piston Ring Set Perkins (Std)

Price Trend : 500.00 - 1000.00 INR

Iron T/C Piston Ring Set Perkins 4.236

Price Trend : 500.00 - 1000.00 INR

Iron T/C Piston Ring Set Perkins 3.152/4.203/6.305 (Std)

Price Trend : 500.00 - 1000.00 INR

Iron T/C Piston Ring Set Perkins 1103A-33T,1104T

Price Trend : 500.00 - 1000.00 INR

Iron T C Piston Ring Set Lombardini Lda 450 Lda 510

Price Trend : 500.00 - 1000.00 INR

Iron Tc Piston Ring Set Perkins 3.152/4.203/6.305

Price Trend : 500.00 - 1000.00 INR

Hydraulic BST Guider

Price: 100 INR/Piece

MOQ10 Piece/Pieces

ThicknessAs per requirement

ApplicationWeb Guiding System in Printing and Packaging Industries

Lubrication TypeSelf-lubricated

Load Capacity60-2000 kg

Surface FinishPolished

Temperature Range-20AdegC to +80AdegC

Piston Ring - OEM & Genuine Parts for Cummins Engines, Compatible with N-495, N-855, ISX Series, Durable and High-Performance Components

Payment TermsLetter of Credit (L/C), Telegraphic Transfer (T/T)

Sample AvailableYes

Sample PolicySample costs shipping and taxes has to be paid by the buyer

FAQs Related to Piston Ring Sets

Who are the top piston ring sets manufacturers in India?

- Satish N Thakkar

- Guru Nanak Iron And Steel Mfg. Co.

- Trident Products Pvt. Ltd.

- Shri Ram Engineers

- S.d. Engg. Works

- Kolben Compressor Spares (india) Pvt. Ltd.

- Fluoroplast Engineers Pvt. Ltd.

- Automount Industries Llp

- Subina Exports

- Goel Trading Co.

Which cities have the largest number of piston ring sets suppliers?

- Mumbai

- Delhi

- Pune

- Chennai

- Bengaluru

- Kolkata

- Hyderabad

- Jaipur

- Rajkot

- Ahmedabad

- Agra

- Faridabad

- Ghaziabad

- Gurugram

- Ludhiana

- Coimbatore

- Howrah

- Wadhwan

- Surat

- Bharatpur

What is the price range for piston ring sets offered by listed companies?

| Company Name | Currency | Product Name | Price |

|---|---|---|---|

| Alfa Engineering Works | INR | Piston Rings | 100 |

| Ganga Enterprise | INR | Piston Ring Set | 650 |

| PRIMEX COMPRESSOR ACCESSORIES PVT. LTD. | INR | Bike Priston Ring Set | 70 |

| Ansh Enterprise | INR | ICS Piston Ring set | 4800 |

| Samarth Industries | INR | Piston Ring Set | 50 |

| INDO COMPRESSOR SPARE HOUSE | INR | Lpr Piston Ring | 250 |

| LR International | INR | Mahindra Maximo Piston Ring Set | 700 |

| JMJ ENTERPRISES | INR | Piston Ring Sets | 100 |

| Balaji Agro Industries | INR | Engine Pistons and Piston Ring Set | 1750 |

How many trusted sellers are available for piston ring sets?

- SUPREME MOTORS

- SHRI RAM ENGINEERS

- P. S. Diesel Spares

- FLOWBIZ EXPORTS PRIVATE LIMITED

- AUTOMOUNT INDUSTRIES LLP

- REAL AIR TECHNOLOGIES PVT. LTD.

- SATISH N THAKKAR

- RENOVA SALES CORPORATION

- BND ENGINEERS PVT. LTD.

- MARUTI ENTERPRISE

- SWASTIK ENGINEERING AND TRADING COMPANY

- Garg Overseas

- Ansh Enterprise

What is the minimum order quantity for piston ring sets?

Do listed companies have registration & certifications?

- SUPREME MOTORS

- SHRI RAM ENGINEERS

- AECO ENGINEERING CO

- BND ENGINEERS PVT. LTD.

- S.D. ENGG. WORKS

What is the get latest price feature?

What types of payment methods are accepted by the piston ring sets suppliers?

Piston Rings - Cast Iron Material, Round Shape, Black Color | Compatible with Diesel Engines: Bus, Tractor, Car, Two Wheeler, Generator

Price: 20 INR/Piece

MOQ100 Piece/Pieces

Product TypePiston Ring

MaterialCast Iron

OE NumberMEC

Renova Sales Corporation

Delhi

Trusted Seller

Trusted Seller Premium Seller

Premium Seller7 Years

Piston Ring Sets - Lubrication Type: Lubricated

Price: 200 INR/Unit

MOQ50 Unit/Units

Control SystemManual

Cooling MethodAir Cooled

Noise LevelLow

Frequency50 Hz

Drive TypeOther, Belt Drive

PhaseSingle & Three Phase

Bnd Engineers Pvt. Ltd.

Ahmedabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller3 Years

Silver Engine Piston Rings

Price Trend: 15.00 - 40.00 INR/Piece

MOQ1000 Piece/Pieces

Surface TreatmentPolished

MaterialStainless Steel

For Use InAutomotive

Product TypeAutomotive Parts

ColorSilver

Piston Ring Set Application: Inboard Boat Engine

Price: 7000 INR/Set

MOQ1 Set/Sets

Product TypeMarine Engine Part

Parts NameOther

ApplicationInboard Boat Engine

OE Number729120-22500

Jcb Piston Ring - Color: Green (Packaging)

Price: 20 INR/Piece

MOQ1 Piece/Pieces

ColorGreen (Packaging)

Product TypePiston Ring

General UseReplacement part for JCB machines

MaterialOther

TypeJCB

FeatureEnvironmental Friendly

Swastik Engineering And Trading Company

Delhi

Trusted Seller

Trusted Seller3 Years

Swift Piston Ring

Price: 1200 INR/Number

MOQ10 Number

ShapeRound

Load CapacityDesigned for OEM Standard Loads

Hardness220-250 HB

Engine TypePetrol & Diesel

Lubrication TypeOil Lubricated

Tensile Strength400-600 MPa

Piston Ring Set - New Condition, Daikin Standard, Gray Color | Industrial Usage, Technical Specifications

Price: 500 INR/Piece

MOQ1 Piece/Pieces

ColorGray

UsageIndustrial

Product TypePiston Ring Set

View More

Gray Mycom L Piston Assembly Piston Pin Ring Set

Price : 900 INR

Mahindra Maximo Piston Ring Set - Size: Standard

Price: 700 INR/Piece

MOQ10 Piece/Pieces

Surface FinishPolished

MaterialOther, Metal

Vehicle TypeMahindra

SizeStandard

UsageAutomobile industry

JCB Piston Set - Silver Finish, Light Weight 0.005-0.05 kg | Manual Control, Quality Assurance, Exceptional Hammering Energy Transfer

MOQ1 , Piece/Pieces

Product TypePiston Set

General UseFor JCB

MaterialOther

Weight (kg)0.005-0.05 Kilograms (kg)

ComputerizedNo

AutomaticNo

Ics Piston Ring Set - Shape: Round

Price: 4800 INR/Piece

MOQ50 Piece/Pieces

Surface FinishPolished

ShapeRound

MaterialOther, Metal

SizeStandard

Compressor TypeAir Compressor

UsageIndustrial

Black And Silver Piston Rings

MOQ1 Unit/Units

Product TypePiston Rings

General UseFor Piston

MaterialRubber, Other

ColorBlack and Silver

Lpr Piston Ring

Price: 250 INR/Set

MOQ100 Set/Sets

ShapeRound

ApplicationIndustrial Use

Product TypePiston Ring

MaterialIron

SizeStandard

UsageIndustrial Use

3948095 6Cta 8.3 Liner Ring Set - Application: Industrial

MOQ1 Piece/Pieces

MaterialCast Iron

FunctionAutomatic

ApplicationIndustrial

SizeCustomized

FeatureCorrosion Resistant

Piston Guide Ring

ToleranceA+-0.02 mm

Hardness60-70 Shore D

FeatureLow friction, Wear resistance, Chemically inert

MaterialPTFE (Polytetrafluoroethylene)

StyleOther, Split / Cut Ring

ShapeRound / Circular

Piston And Ring

MaterialAluminum alloy

DimensionsVary by model

WeightDependent on size

Compression ratioSpecified by model

Bore diameterCustomizable

Ring gapPrecision engineered

Piston Ring - Cast Iron, Diameter 70-100mm, Thickness 2-4mm, Gap 0.2-0.5mm, Honed Finish | ISO 9001 Compliant for Internal Combustion Engines

MaterialCast Iron

Diameter Range70-100mm

Thickness Range2-4mm

Gap Range0.2-0.5mm

FinishHoned

UsageInternal combustion engines, preventing gas leakage and controlling oil consumption.

What are Piston Ring Sets

In a reciprocating engine, a piston ring is a split ring that slides into a groove on the outer diameter of the piston. In reciprocating engines, piston rings have three main functions: to seal the combustion chamber to reduce gas leakage into the crankcase; to improve heat transfer from the piston to the cylinder wall; and to limit the amount of engine oil used by returning scraped oil to the sump.

The purpose of the piston rings is to close the gap between the piston and the cylinder wall. If this gap is too narrow, the piston can seize in the cylinder due to thermal expansion, causing serious damage to the engine. On the other hand, if the gap was too wide, the piston rings would not seal properly against the cylinder walls, resulting in excessive blow-by (combustion gases entering the crankcase) and reduced cylinder pressure, which would reduce engine performance.

The engine suffers friction losses due to the sliding motion of the piston ring inside the cylinder wall. Approximately 24% of the engine's total mechanical friction losses are due to friction induced by the piston rings. The design of the piston rings is therefore a compromise between reducing friction and providing good sealing and a respectable service life.

Types of Piston Ring Sets

Ring Types

The main types of piston rings used in internal combustion engines are compression rings and oil control rings. Suppliers in North America and other countries offer both types of piston rings. There are also compression rings and oil control rings that are CE marked or that meet SAE standards.

Different piston ring designs are required for different engines. Piston rings are fitted into specific grooves cut around the circumference of the piston. The oil control ring groove is usually located below the compression rings and the compression rings are usually mounted in the upper part of the piston.

Benefits of Using Piston Ring Sets

They seal off the gases produced during internal combustion, help transfer heat to the cylinder wall, and then lubricate and remove oil from the wall. It's important to use the right amount of oil. If your engine has too much oil, it may produce blue smoke during combustion, but if it has too little, the engine could eventually seize up.

To ensure you get the most power from your engine, the main function of the top compression ring is to seal off most of the combustion gases. Your engine will operate less effectively than it should if there is any failure or weakening of the piston ring in this area.

The intermediate ring helps with both tasks, playing a finishing role in the combustion seal as well as scraping oil downwards. The bottom ring is primarily responsible for oil control, ensuring that the correct amount of oil is used to lubricate the working surfaces of the cylinder.

The combined action of these three rings ensures adequate lubrication within the cylinder bore, preventing undue wear at all times.

How to Choose the Right Piston Ring Set

Piston ring dimensions and shape

There are two ways of mounting piston rings. They can be mounted on rods or shafts or used as guides in cylinders. To provide the required clamping force and flexibility, guide rings are slotted.

Depending on the shape of the slot, piston rings can be used either as a seal or to allow lubrication or hydraulic fluid to pass through. As well as straight and angled grooves, there are also form-fit variations with a Z or serrated design. Plastic piston rings have the advantage of being less complicated in shape, as they are easy and inexpensive to handle and machine.

Different piston ring materials

There is a wide variety of materials used in the plastics industry. However, not all of them are suitable for use in piston rings. In addition, additives are required to improve the properties of the material for use in piston rings. The main differences between materials are their resistance to temperature, thermal expansion and chemicals, as well as improved properties such as elasticity, coefficient of friction and mechanical stability.

Main functions of piston ring

In engines, piston rings have the following main functions

Seal the combustion chamber to reduce gas leakage into the crankcase.

Improve heat transfer from the piston to the cylinder wall.

Ensure that there is an adequate amount of oil between the piston and the cylinder wall.

Limit the amount of engine oil used by returning scraped oil to the sump.

What are piston ring sets used for?

In engines, piston rings have the following main functions: to seal the combustion chamber to reduce gas leakage into the crankcase; to improve heat transfer from the piston to the cylinder wall; to ensure that there is the correct amount of oil between the piston and the cylinder wall.

What materials are piston ring sets made of?

Pistons are made from low carbon steel or aluminium alloys. The piston is subjected to high temperatures, inertia, vibration and friction. The effects of differential thermal expansion between the piston and cylinder walls are reduced by carbon steels.

How many piston ring sets are required for one engine?

Cast iron and steel are typically used in the manufacture of piston rings. A key requirement for the materials used in their manufacture is wear resistance.

What is the lifespan of a piston ring set?

The total life of a piston ring for a large two-stroke 900mm diameter engine can be up to 24,000 hours, while for smaller 500mm bore engines it can be up to 16,000 hours.

How does the quality of a piston ring set affect engine performance?

It appears that the engine's performance is dropping. Combustion gas leaks are caused by wear between the piston rings and the cylinder, which has an immediate effect on performance.

The top and second rings are responsible for pressing tightly against the cylinder wall and sealing the combustion chamber, preventing oil from entering and combustion gases from escaping.

As the oil ring moves down the cylinder, it scrapes oil off the cylinder wall and deposits it in the oil sump. It is typical for some oil to burn during combustion, as an incredibly thin layer of oil lubricates the ring/cylinder wall interface. However, every engine has a different definition of 'normal' oil consumption.

Piston Ring Sets Price List

Product Name | Expected Price |

|---|---|

| Piston Rings | 100 |

| Piston Ring Set | 650 |

| Bike Priston Ring Set | 70 |

| Ptte Piston Ring | 2000 |

| ICS Piston Ring set | 4800 |

| Piston Ring Set | 50 |

| Lpr Piston Ring | 250 |

| Mahindra Maximo Piston Ring Set | 700 |

| Piston Ring Sets | 100 |

| Engine Pistons and Piston Ring Set | 1750 |

This Data was Last Updated on 2025-12-24

Piston Ring Sets Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Satish N Thakkar Mumbai, India | 19 Years |

Guru Nanak Iron And Steel Mfg. Co. Jalandhar, India | 19 Years |

Trident Products Pvt. Ltd. Gurugram, India | 17 Years |

Shri Ram Engineers Rajkot, India | 16 Years |

S.d. Engg. Works Faridabad, India | 16 Years |

Kolben Compressor Spares (india) Pvt. Ltd. Mumbai, India | 15 Years |

Fluoroplast Engineers Pvt. Ltd. Ahmedabad, India | 14 Years |

Automount Industries Llp Palghar, India | 9 Years |

Subina Exports Delhi, India | 7 Years |

Goel Trading Co. Delhi, India | 7 Years |

Upcoming Tradeshows

CWIEME Shanghai 2026

Wed, 24 Jun, 2026 - Fri, 26 Jun, 2026

INDOMACH Jamshedpur 2026

Thu, 05 Feb, 2026 - Sun, 08 Feb, 2026

Asia Photonics Expo (APE 2026)

Wed, 04 Feb, 2026 - Fri, 06 Feb, 2026

IFF - India Fashion Forum 2026

Wed, 28 Jan, 2026 - Thu, 29 Jan, 2026

Plastic Packaging Printing Expo (P3) 2026

Fri, 10 Apr, 2026 - Mon, 13 Apr, 2026

STEEL CONSTRUCTION EXPO 2026

Thu, 26 Feb, 2026 - Sat, 28 Feb, 2026

Panacea - Natural Products Expo India 2026

Fri, 06 Mar, 2026 - Sun, 08 Mar, 2026

India Boat & Marine Show 2026

Thu, 29 Jan, 2026 - Sat, 31 Jan, 2026

Spectra Expo 2026

Wed, 06 May, 2026 - Fri, 08 May, 2026

Odisha Mining & Infrastructure International Expo 2026

Thu, 08 Jan, 2026 - Sun, 11 Jan, 2026

Popular Categories