- Tradeindia

- Biogas

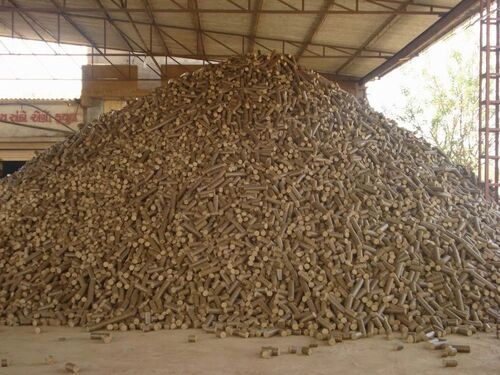

- Groundnut Shell Briquette

Groundnut Shell Briquette

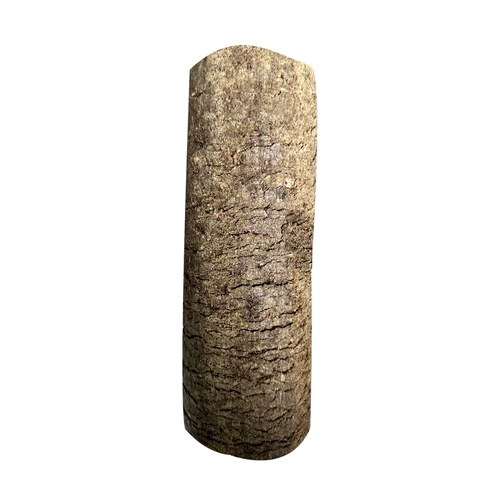

(89 products)50Mm Solid Groundnut Shell Briquette - Density: 1.0 A 1.2 G/Cma Gram Per Cubic Centimeter(G/Cm3)

MOQ1 Piece/Pieces

Product TypeBiomass Briquette

MaterialGroundnut Shell

ApplicationOther, Industrial Boilers, Power Plants

Calory3800 aEUR" 4200 Kcal/kg

Hydrogen Content (%)5 aEUR" 6 %

Methane Content (%)15 aEUR" 18 %

Groundnut Shell Briquette - Ash Content (%): 9%

Price: 7000 INR/Ton

MOQ20 Ton/Tons

Size90 mm

Coal Calorific3800 Kcal/Kg

Gross Calorific Value3800 Kcal

MaterialWood

ShapeCylindrical, Other

Moisture (%)8%

Groundnut Shell Biomass Briquette - Material: Wood

Price: 6200 INR/Ton

MOQ300 Ton/Tons

Product TypeOther, Groundnut Shell Briquette

MaterialWood

ShapeBriquette

Moisture (%)Nil

Sulphur Content (%)98-99%

Phosphorus Content (%)Nil

70Mm Groundnut Briquettes - Ash Content (%): <8%

Price: 9500.0 INR/Ton

MOQ10 Ton/Tons

Gross Calorific Value4000kcal

Size70mm

MaterialGroundnut shell

ShapeCylindrical, Other

Moisture (%)7%

Ash Content (%)<8%

View More

90Mm Groundnut Shell Briquettes - Ash Content (%): 6%

Price : 11500.0 INR

Groundnut Shell Biomass Briquette - Nitrogen Content (%): Below 10%

Price: 10500.00 INR/Ton

MOQ25 Ton/Tons

Product TypeGroundnut Shell Biomass Briquette

MaterialBiomass

ApplicationOther, Boiler

Caloryyes

Nitrogen Content (%)Below 10%

Purity(%)99%

View More

Groundnut Shell Briquette - 90MM Diameter, High Calorific Value, Less Than 10% Moisture, Ideal for Boiler Applications

Price : 10500 INR

Solid Groundnut Shell Briquette - 70 mm Diameter, 50 Kg HDPE Bag | Eco-Friendly Fuel, Low Ash & Moisture Content, High Density

Price : 10500 INR

High Grade Groundnut Shell Briquette

Price : 10000 INR

8Mm Groundnut Shell Pellets - Ash Content (%): Less Than 10%

Price: 7 INR/Kilograms

MOQ10000 Kilograms/Kilograms

Coal Calorific3700kcal/kg

Dimension (L*W*H)8 Millimeter (mm)

MaterialGroundnut Shell

Moisture (%)Below 12%

Fixed CarbonYes

Ash Content (%)Less than 10%

90Mm Groundnut Shell Biomass Briquette - Moisture (%): 10%

MOQ50 Kilograms/Kilograms

SizeSmall

MaterialGroundnut

ShapeBriquette

Moisture (%)10%

Weight50 Grams (g)

80 Mm Groundnut Shell Briquette - Ash Content (%): 8%

Price: 8800 INR/Ton

MOQ1 Ton/Tons

Fuel TypePellet

MaterialOther, Groundnut

ShapeBriquette

Ash Content (%)8%

Size80 mm

View More

60 Mm Groundnut Shell Briquette - Ash Content (%): 8%

Price : 8400 INR

70 Mm Groundnut Shell Briquette - Ash Content (%): 8%

Price : 8600 INR

90 Mm Groundnut Shell Briquette - Ash Content (%): 8%

Price : 9000 INR

90 Mm Groundnut Shell Based Briquettes - Ash Content (%): 3A 5%

MOQ1000 Kilograms/Kilograms

Size90 mm

MaterialGroundnut Shell

Moisture (%)6aEUR"10%

Fixed Carbon15aEUR"20%

Phosphorus Content (%)0.2aEUR"0.5%

Ash Content (%)3aEUR"5%

Groundnut Briquettes - Ash Content (%): Below 5%

Price: 11.25 INR/Kilograms

MOQ100 Kilograms/Kilograms

Gross Calorific Value4200+

MoistureBelow 6%

Ash Content (%)Below 5%

Size90 MM

Groundnut Shell Briquette For Boiler And Heating Application

Product TypeGroundnut Shell Briquette

ApplicationHeating System

View More

Eco Friendly Natural Groundnut Shell Briquettes

Get Best Deal

Groundnut Shell Briquettes Ash Content (%): Nil

Get Best Deal

Black Color Sawdust Briquettes

Get Best Deal

Groundnut Shell Briquettes - 10% Moisture, 750 kg/m3 Density | High Performance Cooking Fuel, Low Smoke Emissions, 99% Purity

Price: 7200 INR/Ton

MOQ5 Ton/Tons

Product TypeGroundnut Shell Briquettes

MaterialGroundnut Shell

ApplicationCooking Fuel

Hydrogen Content (%)5%

Nitrogen Content (%)2%

Sulphur Content (%)10%

Top Rated Products

FAQs Related to Groundnut Shell Briquette

Who are the top groundnut shell briquette manufacturers in India?

- Civicon Infratech

- Shri Krishana Trading Co.

- Haritima Bio Energy

- Aj Bioenergy

- Quality Agrofuel

- Mehta Global Traders

- Herbify India

- Shivsubham Industries Private Limited

- Smart Solutions

- Alfa Beta Biomass Solution

Which cities have the largest number of groundnut shell briquette suppliers?

- Delhi

- Pune

- Jaipur

- Kolkata

- Rajkot

- Coimbatore

- Bikaner

- Surat

- Gurugram

- Junagadh

- Kapurthala

- Neemuch

- Rewari

What is the price range for groundnut shell briquette offered by listed companies?

| Company Name | Currency | Product Name | Price |

|---|---|---|---|

| GAURI WOOD CRAFT | INR | 90 Mm Groundnut Shell Briquette | 10 |

| SOVEREIGN BIO ENERGY | INR | Groundnut Shell Briquette | 150 |

| Shri Krishana Traders | INR | High Grade Groundnut Shell Briquette | 10 |

| PRAJAPATI TRADERS | INR | Groundnut Briquette | 5200 |

| Devi Agro Fuels | INR | Solid Groundnut Shell Briquette | 6500 |

| Akhil Enterprises | INR | Groundnut Briquettes | 90000 |

| SFS ENGINEERS | INR | Groundnut Shell Briquette | 13 |

| SHRI KRISHANA TRADING CO. | INR | Groundnut Shell Biomass Briquette | 10500 |

How many trusted sellers are available for groundnut shell briquette?

- AJ BIOENERGY

- Quality Agrofuel

- CIVICON INFRATECH

- Herbify India

What is the minimum order quantity for groundnut shell briquette?

Do listed companies have registration & certifications?

- Quality Agrofuel

What is the get latest price feature?

What types of payment methods are accepted by the groundnut shell briquette suppliers?

Solid Groundnut Shell Briquettes - Biomass Briquettes, 6% Ash Content, 5% Moisture, High Calorific Value, Environmentally Friendly Fuel Source

Price: 7000 INR/Ton

MOQ10 Ton/Tons

MaterialBiomass Briquettes

ShapeBriquette

Moisture (%)5%

Fixed CarbonYes

Ash Content (%)6%

View More

Solid Groundnut Shell Briquette

Price : 6500 INR

Groundnut Shell Briquettes - Rich Viscous Liquid Core , Industry Fuel Application

MOQ500 Kilograms/Kilograms

Product TypeGroundnut Shell Briquettes

MaterialGroundnut Shell

ApplicationIndustry Fuel

Environment Safe Biomass Briquette For Burning Grade: A

Price: 6000 INR/Kilograms

MOQ20 Metric Ton

GradeA

TypeOther

ApplicationOther

Moisture (%)10

RefinementOther

View More

Groundnut Shell Briquette With 70/90mm GCV 4000+|-5%

Price Trend : 6.00 - 9.00 INR

Eco Friendly And Premium Design Groundnut Briquettes

Price: 90000 INR/Ton

MOQ15 Ton/Tons

Product TypeGroundnut Briquettes

MaterialWooden

ApplicationIndustry Fuel

Purity(%)90

Groundnut Shell Briquette - 99% Pure, 281.43 Kilograms Per Cubic Meter | 55% Hydrogen, 29.8% Nitrogen, 58% Sulfur, Ideal for Cooking and Heating

Price: 5500 INR/Ton

MOQ20 Ton/Tons

Product TypeGroundnut Shell Briquette

MaterialGroundnut Shell

ApplicationIndustry Fuel

Hydrogen Content (%)55%

Nitrogen Content (%)29.8%

Sulphur Content (%)58%

Groundnut Briquettes Weight: As Per Requirement Kilograms (Kg)

Price: 7500 INR/Ton

MOQ20 Ton/Tons

MoistureNil

Product TypeGroundnut Briquettes, Other

MaterialOther

WeightAs per requirement Kilograms (kg)

Brown Groundnut Briquettes

Price: 6800 INR/Ton

MOQ20 Ton/Tons

ColorBrown

TypeGroundnut Briquettes, Other

ApplicationIndustrial, Other

Groundnut Shell Briquette - Material: Groundnut Shell , Size: Customizable, Color: Brown | Calory: 4100 Kcal/Kg, Density: 750 Kg/m3, Eco-Friendly, 100% Purity

Price: 9 INR/Kilograms

MOQ3000 Kilograms/Kilograms

Product TypeGroundnut Shell Briquettes

MaterialGroundnut Shell Briquette

ApplicationIndustry Fuel

Calory4100 Kcal/Kg

Hydrogen Content (%)0%

Sulphur Content (%)55 and 91%

50 Mm Groundnut Shell Pellet Moisture (%): Nil

Price: 20 INR/Kilograms

MOQ100 Kilograms/Kilograms

MaterialGroundnut Shell

ShapeBriquette

Moisture (%)Nil

Groundnut Shell Briquettes - High Efficiency Biofuel, Free From Impurities - Eco-Friendly Alternative To Coal and Firewood

MaterialGroundnut shell

ShapeCylindrical

Diameter50-60 mm

Length100-120 mm

Density650 kg/m³

Ash contentLow

Groundnut Briquette - 90mm Size, GCV 4200, Ash Content 7% | Moisture 8%, Volatile Matter 40%, Sulphur 0.5%

Price: 5300 INR/Short Ton

MOQ20 Short Ton/Short Tons

Coal Calorific4200

Dimension (L*W*H)90 Millimeter (mm)

MaterialGroundnutt briquette

ShapeBriquette

Moisture (%)10

Sulphur Content (%)0.5

Groundnut Briquette

Price: 5200 INR/Ton

MOQ10 Ton/Tons

Product TypeGroundnut Briquette

MaterialWood

ApplicationHeating System

CaloryBrown

Purity(%)100

Groundnut Shell Briquette

Price: 150 INR/Kilograms

MOQ250 Kilograms/Kilograms

Product TypeGroundnut Shell Briquette

MaterialGroundnut Shell Briquette

ApplicationOther, Industrial Boilers, Furnaces, Cooking, Heating Systems

Hydrogen Content (%)4 aEUR" 6%

Methane Content (%)1 aEUR" 2%

Nitrogen Content (%)0.5 aEUR" 1.5%

High Grade Groundnut Shell Briquette

Price: 10 INR/Tonne

MOQ1000 Tonne/Tonnes

Product TypeGroundnut Shell Biomass Briquette

MaterialGroundnut Shell

View More

Groundnut Shell Biomass Briquette

Price : 10 INR

99% Pure Natural Cylindrical Dried Groundnut Shell Briquette Application: Industrial

Price: 6000 INR/Ton

MOQ10 Ton/Tons

Product TypeGroundnut Shell Briquette

MaterialGroundnut Shell

ApplicationCooking Fuel

Hydrogen Content (%)12 %

Purity(%)99 %

Biomass Groundnut Shell Briquette - Durable, Eco-Friendly Cooking Fuel, Made from Groundnut Shell | Ideal for Commercial Use

Price: 90 INR/Kilograms

MOQ5000 Kilograms/Kilograms

Product TypeGroundnut Shell Briquette

MaterialGroundnut Shell

ApplicationCooking Fuel

Latest from Groundnut Shell Briquette

50mm Solid Groundnut Shell Briquette

By:

Aj Bioenergy

Groundnut Shell Briquettes

By:

Shubhshree Biofuels Energy Limited

The decreasing availability of traditional fuel sources such as coal, kerosene coupled with their adverse effects on the environment has led to a greater emphasis on using alternative fuel sources. One of these alternative fuel sources is groundnut shell briquette, which along with being readily available is also a clean energy source. Every year millions of tonnes of groundnut shells are discarded, leading to problems in their disposal. Thus briquet-ting of the shells is slowly being recognized as essential because it solves the aforementioned disposal problem and also generates clean energy.

Groundnut shell briquettes have a low moisture content, high calorific value and generate minimal ash when burned. These are ideal for both domestic as well as industrial heating. The noteworthy thing here is that governments across the world are gradually realizing the importance of these briquettes in their endeavor to provide cheap fuel to all strata of society. As a result, the usage of groundnut shell briquettes is increasing everywhere.

Preparation Process of Groundnut Shell Briquettes

Although groundnut shell briquettes are manufactured in many different ways, still the basic method remains the same. For better illustration, one manufacturing process is explained below;

Groundnut shell residues are collected.

The residues are sun dried until a stable moisture content is achieved.

The residues are then subjected to size reduction process, generally through the use of mortar and pestle.

The residues are then thoroughly mixed with starch gel.

The residues are then put in a briquet-ting machine, the machine makes the residues into uniformly sized briquettes with or without using binders.

The Quality of Groundnut Shell Briquettes Generally Depends on

Particle size of the shells

Compaction pressure

Binder ratio( if binders are being used)

Volatile matter content

Fixed carbon content

Calorific value

Die temperature ( the average temperature inside the briquette making machine during the manufacturing process)

Die geometry

Groundnut Shell Briquettes Can be Used to Power

Boilers

Furnaces

Stoves

Gasifiers

Groundnut Shell Briquette Price List

This Data was Last Updated on 2025-11-25

Groundnut Shell Briquette Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Civicon Infratech Dwarka, India | 3 Years |

Shri Krishana Trading Co. Bhiwani, India | 3 Years |

Haritima Bio Energy Rawatsar, India | 3 Years |

Aj Bioenergy Ahmedabad, India | 1 Years |

Quality Agrofuel Jetpur, India | 1 Years |

Mehta Global Traders Dehradun, India | 1 Years |

Herbify India Faridabad, India | 1 Years |

Shivsubham Industries Private Limited Kolkata, India | 1 Years |

Smart Solutions Greater Noida, India | 1 Years |

Alfa Beta Biomass Solution Jaipur, India | 1 Years |

Upcoming Tradeshows

Pune's 1st Fire, Safety & Security Expo 2026 (PFSS)

Thu, 07 May, 2026 - Sat, 09 May, 2026

17th Coating Korea - Coating Adhesive Film Industry Expo 2026

Wed, 25 Mar, 2026 - Fri, 27 Mar, 2026

Asia Photonics Expo (APE 2026)

Wed, 04 Feb, 2026 - Fri, 06 Feb, 2026

FOOTWEAR INDIA EXPO 2026

Fri, 23 Jan, 2026 - Sun, 25 Jan, 2026

The Harit Bharat Expo 2026

Fri, 16 Jan, 2026 - Sun, 18 Jan, 2026

Power On 2026

Fri, 23 Jan, 2026 - Sun, 25 Jan, 2026

SVUM 2026 INTERNATIONAL TRADE SHOW

Wed, 11 Feb, 2026 - Fri, 13 Feb, 2026

GrainEx India 2026

Fri, 06 Feb, 2026 - Sun, 08 Feb, 2026

CIFF - China International Furniture Fair Guangzhou 2026

Wed, 18 Mar, 2026 - Sat, 21 Mar, 2026

ET TECH X 2025

Thu, 11 Dec, 2025 - Sat, 13 Dec, 2025

Popular Categories