- Tradeindia

- Special Transportation Equipment

- Garbage Compactor

Garbage Compactor

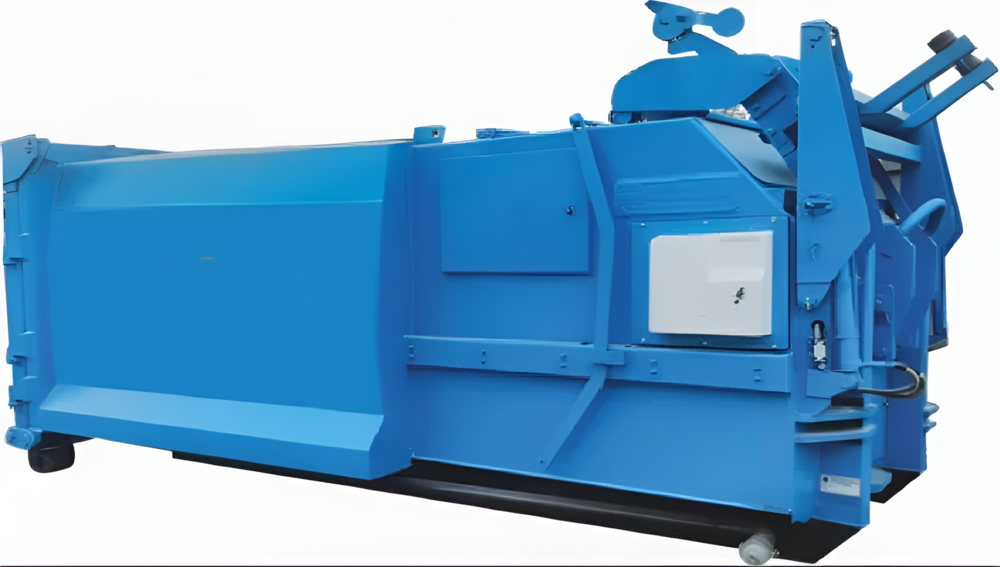

(121 products)Automatic Portable Compactor - General Use: Industrial

Price: 1271186.0 INR/Unit

MOQ1 Unit/Units

Sheet Thickness4mm

Storage MaterialSteel

Fuel TypeDiesal

Usage ApplicationIndustrial

General UseIndustrial

MaterialMild Steel

Faifai Engineering (opc) Private Limited

Ghaziabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Portable Refuse Compactor Bag Size: Extra Large

MOQ1 Piece/Pieces

TypeGarbage Bins

MaterialSteel

Usage LevelIndustrial Level

Bag SizeExtra Large

PortableYes

No of Wheels4

Akisha Engineering Solution Services Private Limited

Ghaziabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller2 Years

Superior Functionality Robustness Long Working Life Refuse And Garbage Compactor

Price: 500000.00 INR/Piece

MOQ1 Piece/Pieces

ConditionNew

Lifting Capacity5 CUM upto 25 CUM Kilograms (kg)

Length of BeltNA Millimeter (mm)

FeatureSuperior functionality Robustness Long working life

Warranty1 year

Quality Enviro Engineers Limited

Ghaziabad

Trusted Seller

Trusted Seller Premium Seller

Premium Seller10 Years

Trash Compactor Van

Capacity6-10 cubic meters

Body MaterialSteel

EngineDiesel

Payload5000 kg

DimensionsVariable

ComplianceBIS

Abcn Manufacturing Pvt. Ltd.

Navi Mumbai

Trusted Seller

Trusted Seller Premium Seller

Premium Seller1 Years

7 Cum Mounted Garbage Compactor

Capacity7 Cum

AutomationSemi-Automatic

WheelsSix wheels

MaterialMild Steel

Chassis16 Ton

Bin Load1100 kg

View More

Portable Garbage Compactor

Price : 1200000 INR

18 Cum Garbage Compactor

Price : 1400000 INR

Mini Garbage Tipper - Iron, 1.7 Cu.M Tipping Bucket Capacity | Efficient Door-to-Door Waste Collection, Direct Unloading into Refuse Compactor

Price : 800000 INR

14 Cum Garbage Compactor

Price : 1000000 INR

Loading Garbage Compactor - Color: Yellow

Price: 750000.00 INR/Unit

MOQ1 , Unit/Units

ColorYellow

MaterialMild Steel, Other

TypeRear End Loading Garbage Compactor, Other

ConditionNew

Fuel TypePetrol

UseContainer / Bottle Cleaning

Omega Machines Tools Corporation

Bahadurgarh

Trusted Seller

Trusted Seller4 Years

View More

Hysraulic Garbage Compactor Truck - Color: White

Price : 750000.00 INR

Garbage Truck - Mild Steel, Large Capacity, Yellow | Refuse Garbage Compactor Truck, Hydraulic Cylinders, Engine Compatibility

Price : 750000.00 INR

Garbage Refuse Compactor - Heavy Duty Steel, 1,500 lbs Capacity | Durable Design, Efficient Waste Management

Price : 750000 INR

Garbage Compactor Truck - Color: White And Blue

Price : 750000.00 INR

Refuse Garbage Compactor

Price: 900000 INR/Unit

MOQ1 Unit/Units

Usage ApplicationMunicipal Solid Waste Management

Storage Capacity8-14 Cubic Meter

Storage TypeContainer

Fuel TypeDiesel

Load Capacity4000-8000 Kg

Sheet Thickness4-6 mm

Rs Enterprises & Engineering Solutions

Saharanpur

Trusted Seller

Trusted Seller2 Years

TUBE COMPACTOR

MOQ10 Unit/Units

Lubricating SystemCentralized

Cooling SystemAir Cooled

Frequency50 Hz

Motor Power2 HP

Voltage220/380 V

Frame TypeHeavy Duty Mild Steel

Garbage Compactor - Advanced Technology Self Loader & Discharger | High Tensile Strength, Low Fuel Consumption, Easy to Operate and Maintain

ColorYellow

Capacity6-10 cubic meters

MaterialSteel

DimensionsVariable

EngineDiesel

UsageMunicipal waste collection and compaction

Automatic Compactor For Bituminous Mixes - 4.5kg Weight, 457mm Drop Height | Fully Automatic Operation, Uniform Compaction, Automatic Blow Counter

Price: 120000 INR/Piece

MOQ1 Piece/Pieces

Product DescriptionAutomatic Compactor For Bituminous Mixes

Garbage Compactor - Steel, 10-20 Cubic Meters | Diesel Engine, 5000-10000 kg Weight, Variable Dimensions, Municipal Waste Management

Capacity10-20 cubic meters

MaterialSteel

DimensionsVariable

Weight5000-10000 kg

EngineDiesel

UsageMunicipal waste collection and disposal in urban areas. Suitable for large-scale waste management operations.

View More

Green Garbage Compactor

Price : 1000000.00 INR

Garbage Compactor - Steel, 50-200 Liters Capacity, Gray | Durable Design, Easy Operation, High Load Bearing, Long Lifespan, CE Compliant

Product TypeWaste Compactor

Dominant ColorGray

MaterialSteel

DimensionsVariable

Capacity50-200 Liters

PowerHydraulic

View More

Garbage Compactors

Get Best Deal

FAQs Related to Garbage Compactor

- Take off the protective plate

- Take the drawer out and the door off

- Spread Baking Powder

- Pour in some dish soap

- Take the garbage compactor out of its case.

Stainless Steel Centralized Standard Garbage Collection System

Price: 25000 INR/Piece

MOQ1 Piece/Pieces

Product TypeCentralized Standard Garbage Collection System

MaterialStainless steel

Hydraulic Garbage Compactor

MaterialSteel

DimensionsVariable

Capacity1-3 tons

EngineDiesel/Petrol

BrakesHydraulic

FeaturesHigh Capacity, Easy Operation, Durable Design, Hydraulic Lift, Efficient Waste, Cost Effective, Safe Operation, Less Maintenance

View More

Rear And Loading Garbage Compactor

Price : 3000000 INR

Heavy Load Garbage Compactor

Price : 175000-200000 INR

Semi-Automatic Rear End Loading Garbage Compactor

MaterialMild Steel

Capacity7 Ton

Pressure170 bar

Cycle Time20 sec

FinishPolished

GradeSemi-Automatic

View More

Mobile Garbage Compactor Vehicle

Price : 288500 INR

Garbage Van

Chassis materialSolid iron

ColorBlue

Tyre typeSturdy

SeatingCushioned

Motor typeHigh grade

Battery typeEnergy efficient

Garbage Compactor - Steel, 1000x500x750 mm | 100 kg/day Capacity, Durable Design, Fast Composting, Easy Operation, Customizable

Dimensions1000x500x750 mm

MaterialSteel

Capacity100kg/day

Power220V, 10A

Weight200 kg

Processing time24 hours

Multifunction Medical Waste Processor High Temperature Sterilization Machine(10Kg)

MaterialSteel

Dimensions100x50x80cm

Weight100kg

Power220V

Capacity10kg

Temperature300°C

Garbage Refuse compactor

MaterialSteel

DimensionsVary

CapacityVariable

EngineDiesel

Speed160km/h

WeightHeavy

7-8 Ton Load Capacity Garbage Compactors For Commercial Use

Payload7-8 tons

MaterialMetal

ConditionNew

FinishPolished

OriginIndia

FeaturesHigh capacity, Durable build, Easy operation, Efficient compaction, Cost effective, Safe operation

Dumper Places & Garbage Compactors

materialsNA

dimensionsNA

vehicle typeMunicipal utility

cylinder typeHydraulic

applicationGarbage compactors

working environmentHarsh

Refuse Compactor - Stainless Steel, Customized Cylinder Design | Durable for Commercial Destructors, Easy Operation Under Tough Conditions

MaterialStainless steel

Cylinder designAs per needs

ApplicationCommercial

OperatingUnder tough

Wide rangeAvailable

CustomizableAvailable

Refuse Compactor - Steel Body, Variable Capacity, Green Color | Efficient Operation, High Torque, Automatic Emptying, Durable Design

Product TypeWaste Compactor

Dominant ColorGreen

CapacityVariable

DimensionsVariable

MaterialSteel

Motor PowerVariable kW

Hydraulic Cylinders For Dumper Placers And Garbage Compactors

MaterialSteel

DimensionsCustomizable

Pressure RatingHigh

Bore SizeVariable

Stroke LengthAdjustable

Mounting OptionsMultiple

Garbage Compactor - Steel, Volume 7-20 m3, GVWR 11-25 Tons | Truck Mounted, 4:1 - 6:1 Compaction Ratio, Cost Savings, Efficient Compaction, Increased Capacity

ModelRCV66-RCV20

Volume7-20 m3

GVWR11-25 Tons

Chassis TypeTruck Mounted

Compaction Ratio4:1 - 6:1

MaterialSteel

Garbage Compactor - 6-16 m³ Body Volume, 0.2-1 m³ Multipack & R Container Types | Collect, Compact, Store & Dump Efficiently

body_volume6-16 m3

container_typeMultipack & R

container_volume0.2-1 m3

dumping_sideAvailable

proven_systemYes

garbage_handlingUnique

View More

Flat Bed Trailer

Get Best Deal

Highly Efficient Garbage Compactor

ColorGreen

MaterialSteel

CapacityVariable

DimensionsCustomizable

WeightVaries

EngineDependent on model

Garbage Compactor Price List

Product Name | Expected Price |

|---|---|

| Garbage Hopper Tipper Dumper | 95000 |

| Refuse Garbage Compactor | 900000 |

| Garbage Compactor | 288500 |

| Automatic Portable Compactor | 1271186 |

| Long Lasting Corrosion Resistance Mild Steel Garbage Compactors | 205000 |

| Garbage Compactor | 150000 |

| Semi-Automatic Rear End Loading Garbage Compactor | 850000 |

| Portable Garbage Compactor | 1200000 |

| 14 Cum Garbage Compactor | 1000000 |

| 18 Cum Garbage Compactor | 1400000 |

This Data was Last Updated on 2025-12-24

Garbage Compactor Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Quality Enviro Engineers Limited Ghaziabad, India | 10 Years |

Chemtex Technologies (p) Ltd. New Delhi, India | 10 Years |

Engineering Solution Services Ghaziabad, India | 4 Years |

Omega Machines Tools Corporation Bahadurgarh, India | 4 Years |

Mkp Equipments Madurai, India | 3 Years |

Faifai Engineering (opc) Private Limited Ghaziabad, India | 2 Years |

Akisha Engineering Solution Services Private Limited Ghaziabad, India | 2 Years |

Rs Enterprises & Engineering Solutions Saharanpur, India | 2 Years |

Abcn Manufacturing Pvt. Ltd. Navi Mumbai, India | 1 Years |

Kaizen Envirotech Industries Pune, India | 1 Years |

Upcoming Tradeshows

CWIEME Shanghai 2026

Wed, 24 Jun, 2026 - Fri, 26 Jun, 2026

INDOMACH Jamshedpur 2026

Thu, 05 Feb, 2026 - Sun, 08 Feb, 2026

Asia Photonics Expo (APE 2026)

Wed, 04 Feb, 2026 - Fri, 06 Feb, 2026

IFF - India Fashion Forum 2026

Wed, 28 Jan, 2026 - Thu, 29 Jan, 2026

Plastic Packaging Printing Expo (P3) 2026

Fri, 10 Apr, 2026 - Mon, 13 Apr, 2026

STEEL CONSTRUCTION EXPO 2026

Thu, 26 Feb, 2026 - Sat, 28 Feb, 2026

Panacea - Natural Products Expo India 2026

Fri, 06 Mar, 2026 - Sun, 08 Mar, 2026

India Boat & Marine Show 2026

Thu, 29 Jan, 2026 - Sat, 31 Jan, 2026

Spectra Expo 2026

Wed, 06 May, 2026 - Fri, 08 May, 2026

Odisha Mining & Infrastructure International Expo 2026

Thu, 08 Jan, 2026 - Sun, 11 Jan, 2026

Popular Categories