- Tradeindia

- Pollution Control & Monitoring Equipment

- Dust Collector

Dust Collector

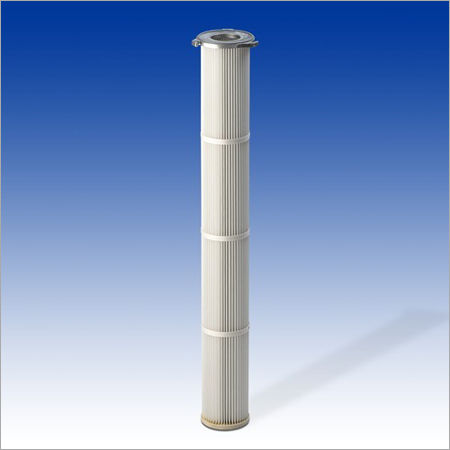

(1923 products)Dust Collector Filter - Color: White And Silver

5000 INR/Unit

MOQ5 Unit/Units

Weight2-5 Kilograms (kg)

ColorWhite and Silver

UsageFor Pollution control

SizeAs per customer requirement

Product TypeDust Collector Filter

ConditionNew

View More

Dust Collector Filter Bags - Color: White

Price : 3000.0 INR

Dust Filter Cartridges 150 mm

Price : 5500.0 INR

Dust Collection Cartridge - High-Quality Filtration, Efficient Dust Capture for Pharmaceutical, Automotive, and Woodworking Industries

Price : 3500.0 INR

Filter Element For Food Contact

Price : 3200.0 INR

Industrial Dust Filter - Color: Silver

Price : 8000 INR

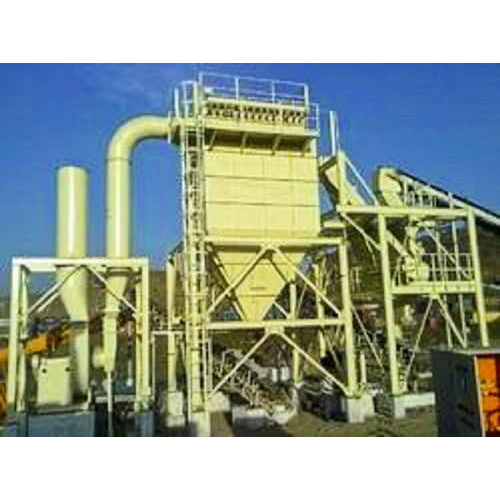

Pollution Control Dust Collector - 14000 CFM, Full Automatic Operation, 220-240 Volt Power Supply

Price: 1000000 INR/Pair

MOQ1 Pair/Pairs

Product TypePollution Contorl Dust Collector

Automatic GradeFull Automatic

Voltage220 to 240 volt

Rbm Green Airfil

Vadodara

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller Super Premium

Super Premium Super Seller

Super Seller6 Years

Super Premium

Super PremiumView More

Metal Camfil Zephyr Iii Portable Dust Collector

Price : 700000 INR

Dust Collector Camfil Farr - Material: Metal

Price : 800000 INR

Metal Camfil Zephr Series Portable Dust Collector

Price : 400000.00 INR

Pulse Jet Dust Collector - Capacity: 5000 M3/Hr

Price: 208000 INR/Unit

MOQ1 Piece/Pieces

Usage & ApplicationsDust Collector

Product TypeJet Dust Collector

MaterialMild Steel

Cooling SystemAir Cooling

Noise Level50 db

Reactor Thickness8000 Millimeter (mm)

Vayuvents Private Limited

Vasai

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller Super Seller

Super Seller4 Years

View More

Dust Collector System - Mild Steel, 200 kg Capacity, Fully Automatic | 1 Year Warranty, 415V Voltage, Industrial Usage

Price : 400000 INR

Dust Collector - Mild Steel, 415 Volt, 8000 cfm Air Capacity | Automatic Operation, 99.9% Filtration Efficiency, Easy Install and Maintenance

Price : 250000 INR

Mild Steel Cyclone Dust Collector - Voltage: 440 Volt (V)

Price : 96000 INR

Pulse Jet Dust Collector System - Material: Mild Steel

Price : 160000 INR

Cyclone Dust Collector System - Material: Stainless Steel

Price : 125400 INR

Dust Collector - Material: Mild Steel

Price : 95000 INR

Sanding Dust Collector - 99% Efficiency, Mild Steel, 230 Volt, 1-Year Warranty | Rugged Design, Easy Installation, Captures 0.5 Micron Dust

Price: 60000 INR/Unit

MOQ1 , Number

Usage & ApplicationsIndustrial

Efficiency99%

MaterialMild Steel

Voltage230 Volt (v)

Warranty1 Year

View More

Dust Collection Unit - Versatile Adaptable Design | Low Maintenance, Efficient Dust Evacuation for All Equipment

Get Best Deal

Portable Dust Collector - NR, CR, NBR, SBR Materials | 120-240V, 99.8% Efficiency, Ideal for Medical, Woodworking, and Food Industries

Price : 30000 INR

Single Phase Vertical Bag Dust Collector - Efficiency: 99%

Price : 32000 INR

Dust Collecting Equipment - Efficiency: 99.8%

Get Best Deal

Woodworking Dust Collector Voltage: 120-240 Volt (V)

Price : 40000 INR

Cartridge Dust Collector - Efficiency: 99.9%

Price : 40000.00 INR

Pulse Jet Dust Collector - Metal, 10000 CFM Airflow, 415 Volt Power | 99.9% Dust Removal Efficiency, Easy Operation

Price: 400000 INR/Unit

MOQ1 Unit/Units

Product TypeDust Collector

MaterialMetal

Ultra Febtech Private Ltd.

Ahmedabad

Trusted Seller

Trusted Seller Super Premium

Super Premium Super Seller

Super Seller4 Years

Super Premium

Super PremiumDust Collector Spares (Parts)

Price: 40000 INR/Unit

MOQ1 Unit/Units,

Supply Ability1 Per Month

Delivery Time3-2 Week

P-square Technologies

Pune

Trusted Seller

Trusted Seller Super Premium

Super Premium Super Seller

Super Seller16 Years

Super Premium

Super PremiumDust Filter Cartridges 335-302 mm

MOQ5 Unit/Units

Supply Ability1 Per Week

Delivery Time1 Week

Sample AvailableYes

R+b Filter Manufacturing Enterprises Pvt. Ltd.

Vadodara

Trusted Seller

Trusted Seller Super Premium

Super Premium15 Years

Super Premium

Super PremiumView More

Industrial Dust Filter - Color: Silver

Price : 8000 INR

Dust Collector Bags - Non Woven, 4 Inch Round, 10 Inch Length, White | High Functionality, 1 Year Warranty, Superior Air Quality Improvement

Price : 2700.0 INR

Dust Collector Filter - Color: White And Silver

Price : 5000 INR

Dust Collector Filter Bags - Color: White

Price : 3000.0 INR

Dust Filter Cartridges 150 mm

Price : 5500.0 INR

Air Cyclone Dust Collector - Dimension (L*W*H): 1.0 X 0.5 X 1.7 Meter (M)

Price: 75000 INR/Unit

MOQ1 Unit/Units

Product TypeAir Cyclone Dust Collector

MaterialMS

Cooling SystemAir Cooling

Reactor Thickness3 Millimeter (mm)

Voltage415 Volt (v)

Weight1100-1200 Kilograms (kg)

Balkrishna Boilers Pvt. Ltd.

Ahmedabad

Trusted Seller

Trusted Seller Super Premium

Super Premium Premium Seller

Premium Seller6 Years

Super Premium

Super PremiumView More

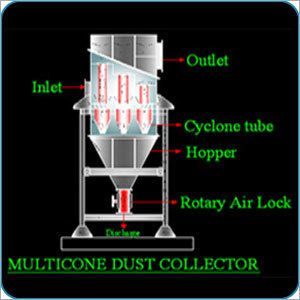

Multi Cyclone Dust Collector - Capacity: 100000 Cumph Milliliter (Ml)

Price Trend : 69000.00 - 100000.00 INR

Dust Collector - MS, 150 x 500 x 1500 mm | 99.99% Efficiency, 340 Volt Operation, 2300 kg Weight

Price : 75400 INR

Cyclone Cooling Dust Collector - Material: Ms

Price : 75500 INR

Fabric Bag Dust Collector - Efficiency: 99%

Price: 300000.00 INR/Unit

MOQ1 Unit/Units

Usage & ApplicationsDust Collector

Efficiency99%

MaterialStainless Steel

Cooling SystemAir Cooling

Warranty1 Year

Orbitech Shotblast Llp

Vadodara

Trusted Seller

Trusted Seller Super Premium

Super Premium9 Years

Super Premium

Super PremiumView More

Structure/Scaffolding Shot Blasting Machine

Price : 300000.00 INR

Dust Collector System - Mild Steel, Water Cooling | Efficient Dust Management Solution for Industrial Applications

Get Best Deal

Pulse Jet Bag Dust Collector - Efficiency: 99%

Price : 300000.00 INR

Dust Collector Application: Industrial

Price: 1000 INR/Unit

MOQ1 Unit/Units

ColorSilver

Product TypeDust Collector

MaterialSteel

FinishPolished

UsageIndustrial

ApplicationIndustrial

Knovocon Private Limited

Howrah

Trusted Seller

Trusted Seller Super Seller

Super Seller3 Years

Dust Collector - Mild Steel Construction | Premium Engineering Metals, Smooth Anti-Corrosion Coating, Long Service Life, Enhanced Air Quality Management

Price Trend: 10000.00 - 50000.00 INR/Unit

MOQ1 , Unit/Units

Product TypeDust Collector

MaterialMild steel

Re Blowers India Private Limited

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller15 Years

Ms Portable Dust Collector - Color: Siemens Grey

Price: 18000.00 INR/Unit

MOQ1 Unit/Units

ColorSiemens Grey

Product TypeOther

TechnologyOther

MaterialSS/ MS+FRP/ MS

Power SourceElectricity

Cooling SystemAir Cooling

United Air Tech Industries

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller17 Years

View More

Stainless Steel Portable Dust Collector - Customized Dimensions, 85% Efficiency | Non Woven Pleated Bag Filters, Versatile Industrial Applications

Price : 100000.00 INR

Dust Collection Systems - Color: Siemens Grey

Price Trend : 65000.00 - 500000.00 INR

Small Capacity Dust Collection System - Automatic Grade: Semi-Automatic

Price Trend : 45000.00 - 1000000.00 INR

Manual Cleaning Dust Collection System - Color: As Per Customer Specs

Price : 150000.00 INR

Reverse Pulse Jet Type Mini Dust Collector - Automatic Grade: Full Automatic

Price Trend : 35000.00 - 200000.00 INR

Dual Cyclone Bag Filter Dust Collection System - Color: Siemens Grey

Price Trend : 65000.00 - 500000.00 INR

Powder Recovery Unit - Dimension (L*W*H): 8X6X4 Meter (M)

Price: 150000 INR/Piece

MOQ10 Piece/Pieces

Product TypePowder Recovery Unit

MaterialAluminium

Cooling SystemAir Cooling

Voltage420 Volt (v)

Weight200 Kilograms (kg)

Dimension (L*W*H)8x6x4 Meter (m)

Laxmi Udyog

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller14 Years

View More

Portable Dust Collector - Customizable Shapes, Advanced Dust Capture Technology for a Clean Environment

Get Best Deal

Cartridge Filter Dust Collector - High-Durability Design | Efficient Air Ventilation for Diverse Applications

Get Best Deal

Portable Dust Collector - Capacity: 200-800 Kg/Hr

Price : 150000 INR

Highly Demanded Industrial Dust Collector

Get Best Deal

Cartridge Filter Dust Collector - Automation Grade: Automatic

Price : 150000 INR

Top Rated Products

Air Cyclone Dust Collector - Dimension (L*W*H): 1.0 X 0.5 X 1.7 Meter (M)

Balkrishna Boilers Pvt. Ltd.

FAQs Related to Dust Collector

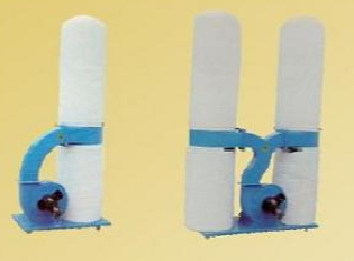

Wood Dust Collector - Voltage: 415 Volt (V)

Price: 30000 INR/Piece

MOQ1 , Piece/Pieces

Product TypeWood Dust Collector

Voltage415 Volt (v)

Laxsun Envirotech Private Limited

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller4 Years

Multi Cyclone Dust Collector - High-Efficiency Filtration System | Robust Design, Silent Operation, Compact Size

Price Trend: 10000.00 - 100000.00 INR/Inch

MOQ1 Piece/Pieces

Supply Ability1 Per Day

Delivery Time1 Days

Microtech Boilers Private Limited

Ahmedabad

Trusted Seller

Trusted Seller Super Seller

Super Seller9 Years

Dust Collector By Sri Vsk Engineerings

Payment TermsCash in Advance (CID)

Delivery Time10 Days

Sample PolicySample costs shipping and taxes has to be paid by the buyer

Dust Collector - DC-21, DC-32, DC-74 Models | Horizontal Design, Single to Four Bag Capacity

Price: 130000.00 INR/Piece

MOQ1 , Unit/Units

Machine TypeOther

Machine StyleHorizontal

Capacity0.2 to 2 Milliliter (ML)

Golden Machinex Corporation

Kolkata

Trusted Seller

Trusted Seller Super Seller

Super Seller6 Years

Industrial Dust Collector System For Pollution Control

Price: 100000 INR/Piece

MOQ01 Piece/Pieces

Product TypeDust Collector

Rajdeep Engineering Systems Pune Private Limited

Pune

Trusted Seller

Trusted Seller Super Seller

Super Seller3 Years

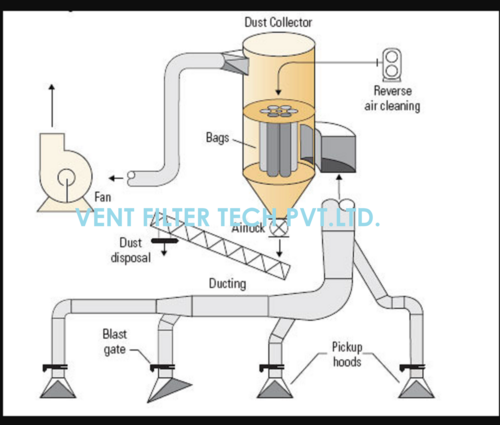

Pulse Jet Dust Collector - Fully Automatic, Self-Cleaning Unit | Efficient Continuous Flow with Electronic Timer and Pneumatic Valve

Product DescriptionWe are engaged in manufacturing, exporting, distributing and supplying excellent quality Pulse Jet Dust Collector in Ahmedabad, Gujarat, India. "VENT" Dust Collector are useful in wide variety of process equipment for chemical, dyes, cement, pharmaceutical, pigments, fertilizer, petrochemicals, Ther

Vent Filter Tech Pvt. Ltd.

Ahmedabad

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller8 Years

View More

Pulse Jet Dust Collector Processing Time: 4 Week

Price : 160000 INR

Customer Requirement Dust Collector Filter

Price : 35000.00 INR

Dust Collector Filtration System Capacity: As Per Design Kg/Hr

Price : 1,50,000 INR

Dust Collector Warranty: .

Price Trend: 17000.00 - 32000.00 INR/Piece

MOQ1 Piece/Pieces

Warranty.

Industrial Dust Collector - Metal Structure, Versatile Sizing Options | Efficient Air Purification System for Factories

Price Trend: 35000.00 - 60000.00 INR/Unit

MOQ1 Unit/Units

Product TypeDust Collector

MaterialMetal

Nandini Machine And Tools

Pune

Trusted Seller

Trusted Seller Super Seller

Super Seller4 Years

View More

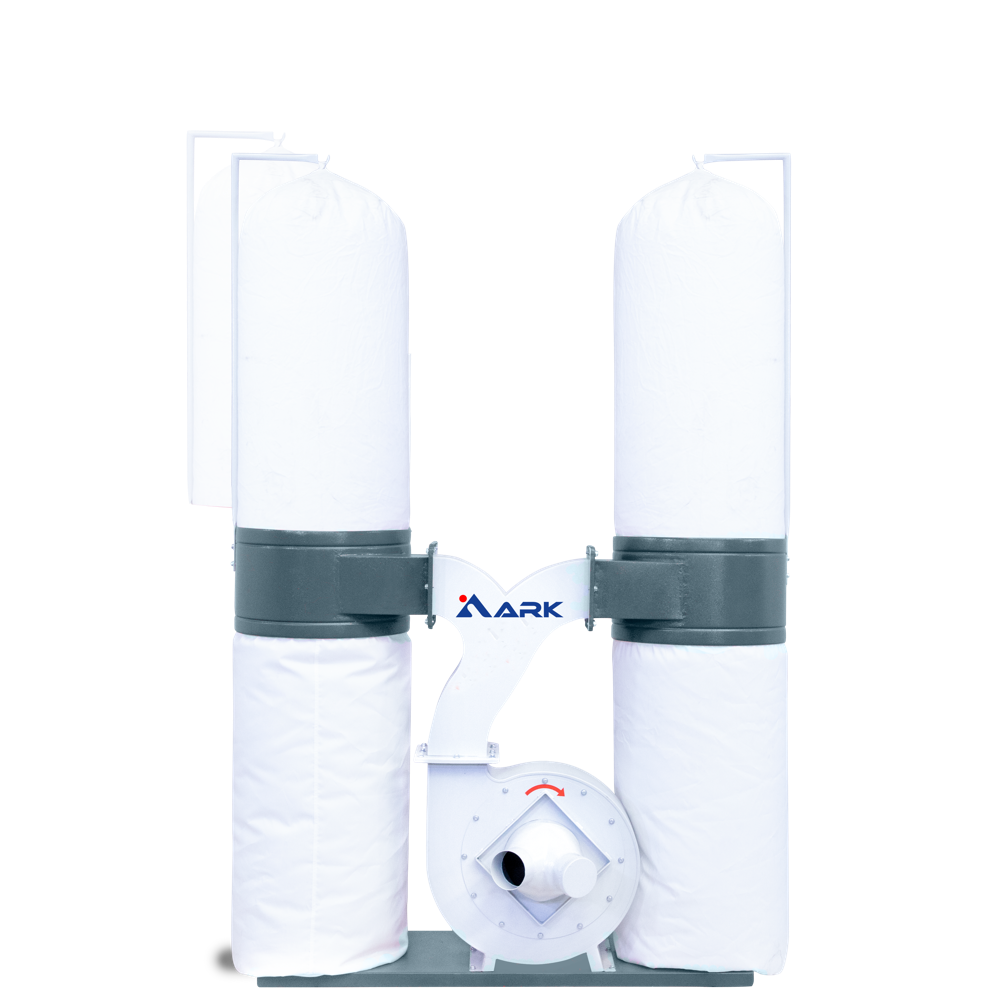

Dust Collector Blower - Electric Power Mode, New Condition | Ideal for Woodworking Industries, Sleek White Design

Price : 42000 INR

Metal Reusable Dust Collector

Price Trend : 34000.00 - 60000.00 INR

Mechanical Dust Collector Voltage: 415V-440V

Price: 100000 INR/Piece

MOQ1 Unit/Units

Product TypeDust Collector

Voltage415V-440V

Aerotech Equipments And Projects Private Limited

Greater Noida

Trusted Seller

Trusted Seller Super Seller

Super Seller2 Years

View More

Kitchen Scrubber Voltage: 415V-440V Volt (V)

Price : 65000 INR

Pulse Jet Dust Collector - Material: Steel

Price : 125500 INR

Dust Collector Cyclone System

Price : 65000 INR

Dust Collectors - Material: Steel

Price : 150000 INR

Portable Dust Collector - Material: Steel

Price : 75000 INR

High Efficiency Dust Collector - High Quality Raw Material, Advanced Manufacturing Techniques, Exceptional Filtration Performance

Payment TermsOthers, Letter of Credit (L/C), Telegraphic Transfer (T/T)

View More

White & Red Dc-3-1B Single Bag Dust Collector

Price : 31000.0 INR

White & Red Dc-3-2B Double Bag Dust Collector

Price : 33500.0 INR

Mild Steel Dust Collector Filter Bags

Price Trend : 15000.00 - 60000.00 INR

Dust Collector By Timus Tooling System Private Limited

Product DescriptionDust Collector

Timus Tooling System Private Limited

New Delhi

Trusted Seller

Trusted Seller Super Seller

Super Seller10 Years

ROTARY AIR FILTER WITH DUST COLLECTOR

Product DescriptionOUR ENGINEERS DEVELOPED TEXT-AIR HUMIDIFICATION AND FILTRATION PLANT WHICH LIMITS THE DUST AND FIBER FLY CONCENTRATION AND MAINTAINS PRECISE HUMIDITY EQUALLY IN THE WORKING AREA. IN TEXTILE MILLS PRODUCTS QUALITY AND PRODUCTIVITY DEPENDS ON RELATIVE HUMIDITY CONTROLLED WITHIN PRESCRIBED LIMITS

Manvi Textile Air Engineers Pvt. Ltd.

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller2 Years

High Performance Dust Collectors

MOQ1 Piece/Pieces

Payment TermsCash on Delivery (COD), Cash Against Delivery (CAD), Cheque, Cash Advance (CA)

Sample PolicyContact us for information regarding our sample policy

Main Domestic MarketGujarat

Industrial Mist Extractors

MOQ1 Unit/Units

Usage & ApplicationsUsed to minimise oil impurities in the air

Product TypeMist Extractors

MaterialMild Steel

Voltage220 Volt (v)

Smms Engineering Systems Pvt. Ltd.

Mumbai

Trusted Seller

Trusted Seller Super Seller

Super Seller17 Years

Latest from Dust Collector

Popular Dust Collector

Dust Collector: Offering Solution to Improve the Air Quality

Dust collectors used to function to clean the air to improve the quality. It helps to remove dust and any other kind of impurities to provide clean and hygienic air to inhale. These are available in different types to offer accessibility of clean air in industrial, and commercial environments. It is used to function in three steps capturing, separating, and releasing. In capturing, collectors collect the dust and particulate from the air. Next, a filter is used to separate the dust from the air. At last, it releases the clean air into the environment. It is a device used to handle large volumes of dust and helps to create a safe workspace for living and operating the task. It is available in different types according to the functioning of different space areas. Single-stage, baghouse, wet dust collector, and pulse jet dust collector are the different types of it.

Some Important Benefits of Dust Collector for Workplace

Equipment to collect dust is used for the development of quality atmospheres in industries. It provides exceptional quality features to maintain the standards of the business. It operates by collecting dust and particulates from the air. It functions with a filter, separates the matter, and releases back the purified air in the environment. Now, look forward to the development of a workplace with important benefits.

-

Improves the Quality of Air

The atmosphere of the workplace always matters a lot. In that case, maintaining a hygienic environment will add more productivity to the business. Every business needs a proper place to work and proceed with the development of business operations. So, it helps to remove the harmful particles and fumes from the air. It helps to improve the health of workers and reduce the risk of catching fire.

-

Provides a Safe Working Environment

The environment of the workplace must be free from any kind of health issue. In the workplace, many operations are associated with creating an atmosphere for respiratory problems and other health issues. In this case, it helps to prevent respiratory problems and other health issues. It reduces the content of dust and any other particulates from the air.

-

Improves the Efficiency of the Workplace

The working environment is always used to lead towards the success or failure of a business. In the scenario of the workplace, any kind of hindrance will create problems in doing the work. It gives the path to maintain a safe working environment and provide an efficient environment for the workers or team members. It helps to prevent the dust from contaminating the machines, equipment, and air particles.

-

Helps to Control the Air Pollution

Degrading the quality of air leads to the problem of health issues. It operates to function for better living conditions for the people. It collects the dust from the premises or workplace to be transferred safely from the air to the dustbin. Overall, it leads to creating a helpful hand from the business and provides safe execution of processes in nature. It allows the environment to be clean and sustainable.

-

Proves Much Cost Saving Option

Dust collectors prove used to function for cleaning the environment. It also provides help to recirculate the air to save money on heating, cooling, and conditioning. It works naturally by collecting dust particles and allows it to maintain the temperature of the workplace environment. It works much better than any other option to save money.

How Dust Collector Used to Operate?

Dust collectors used to function for the improvement of air quality and helped to provide a safe working environment. It operates to collect dust and particulates from the air. After collecting the particulates, it releases the clean air back into the environment or workplace. It is used to process with a simple algorithm to operate:

- Intake of Air: It is used to function with ducts where fans push or pull the impure air into the collector. It operates to draw the air into the system.

- Slow down of Air: The equipment is equipped with baffles, which are angles according to control the flow of air. It slows the speed of air and controls the airflow to get hit with the full speed.

- Separation of Dust: The air passes inside the filter of the dust collector and separates the dust particles and any kind of particulates from the air.

- Collection of Dust: The filter-out dust is collected in the drum at the bottom part of the collector. It used to function for the separation of dust from the air.

- Discharging the Dust: It is associated with a flapper valve that discharges the dust into the funnel. The user removes the dust from the funnel.

- Release of Clean Air: The clean air is again circulated back into the environment. It helps to make the environment clean with its simple algorithm of operation.

Types of Dust Collectors

-

Cyclone Dust Collectors

A cyclone dust collector uses centrifugal force to remove dust and other particles under the pressure of air or gas streams. It helps improve air quality by separating particles from it. All the heavier particles are collected at the bottom of the chamber. Cyclone dust collectors are widely used in industries to protect equipment and maintain a better quality of air.

-

Cartridge Dust Collectors

This type of air purifying collector uses pleated fabric filters to increase the surface area. It allows the air from cylindrical or oval-shaped filter cartridges. The dust particles get captured inside the filter and then pass the filtered air back to the environment. The cartridge can be cleaned with compressed air from the pulse-jet system which blows the air to remove the dust. It’s much more energy-efficient, economical, and safe to use. It’s used in many industrial and manufacturing units to control industrial dust and fumes.

-

Wet Scrubbers

A wet scrubber is a suitable option for different temperatures and the environment. It operates to bring the gas stream in contact with liquid like water. With the use of liquid, all the gaseous pollutants dissolve in the liquid. It captures the solid pollutants in the liquid. This type of air purifying system is suitable to control airborne pollutants and odors in many industries. It’s less expensive and able to process hot and sticky materials.

-

Baghouses Filters

A bag house filter contains fabric filter bags to collect dust and other particles from the air. It helps to trap the contaminants from the air in industries. It’s a soluble solution to control pollution in sectors like food, power plants, and steel mills. It works with tubes, envelopes, or cartridges to remove the dust from the air. Its range of efficiency is more than or up to 99%.

-

Portable Dust Collector

It’s a portable air purifier system to collect dust from different areas of industries. It’s acceptably known as source collectors to reduce the contamination from the air. It works with low pressure and runs continuously to improve the quality of air. It has different components like a blower, filter, dust collection bag, dust collection hose, and cyclone separator. It has the capacity to collect the dust from the source.

-

Pulse Jet Dust Collector

A pulse jet dust collector is known as a dry filtration system to remove dust and air particles with the use of compressed air. It works to purify the air by removing the fine lint, grains, cellulose, and sander dust. In this dust collection equipment, impure air enters the collector, fans move the air, air hits baffles to get slow, air passes to the dirty air plenum, and dust falls into the collector after getting free from filter bags.

-

Shaker Dust Collector

It works with a shaking system to filter the particles like wood chips to detach from the air flows. It is a medium-sized and efficient system to purify the air in places like woodworking shops. It has compartments for continuous cleaning of the air. The shaking system used to work automatically and manually.

Applications of Dust Collectors

1. Welding, Laser Cutting, and Plasma Cutting

The fumes and particles are the waste developed in sectors like welding, laser, and plasma cutting. Here, the use of a perfect air purifying machine is essential to prevent any kind of health issues. So, collecting the dust is required for the ideal functioning of the businesses.

2. Woodworking

In woodworking spaces, the particles of wood are in the air. It contains many essential functions to reduce the amount of particles in the air. It takes very little time and operates continuously to make the air clean to inhale.

3. Food Processing

A good air purifying system is essential to reduce the problem in the food processing and manufacturing industry. It works to maintain the ideal atmosphere of the industry. It allows us to deliver quality products and provide healthy solutions to work in the business.

4. Chemical Processing

In chemical processing, it’s used to improve the quality of air, make a safe environment to work, and prevent cross-contamination. It helps to provide quality air to inhale in the chemical manufacturing and processing industry by capturing the toxic dust. It works well with airborne dust and particles, which include toxic, combustible, and nuisance dust.

5. Paper and Metal Packaging Materials

In the paper and metal packaging industry, the purification of air is essential to provide a safe environment to workers. The dust and particles are required to be removed from the air. The small metal particles can create a problem in inhalation of air. So, the right dust collection equipment will help to reduce the problem.

Maintenance Tips of Dust Collectors

-

Proper Checking of Filters

Regularly check the filter for the cake of dust. It must dry and not get caked. You have to do the checking about the condition of the filter like uneven color, any tear or rip. It must be changed in this condition to operate the functioning of it.

-

Hopper must Empty

You must look to check the hopper is empty and free from any kind of debris. It must be used in a storage bin to collect the dust. Already set debris inside the hopper will not function properly.

-

Inspection Of Cleaning System

Inspect the cleaning system daily. Whether the system is working properly or not. Check all the components functioning like diaphragm valves, controller settings, solenoid valves, and electrical settings.

-

Check About the Leakage

You need to check about the leakage or blockage in the airline, compressed air connections, and pulse pipe alignment. Any type of leakage will cause delay in the functioning of the system.

-

Monitoring of Differential Pressure

Check the differential pressure condition of the filter system and monitor the pressure. It helps to make the system with optimal required pressure for a longer period of time.

-

Check for Exhaust Fan Functioning

Properly check the functioning of the exhaust fan. It is required to send ventilation air through the dust collector filter and out of the exhaust stack.

-

Wear Safety Protective Equipment

Always wear protective equipment to protect the ear as the noise level can be high when testing the pulse valves.

-

Follows the Instructed Rules

Always do the checking and cleaning process with the instructions of manufacturers. It helps to operate machines properly and regularly.

Tips to Select the Right Dust Collector

Selecting the perfect machine or any equipment is essential to do the task. Some special things are required to remember before selecting the dust collector.

-

Type of Dust

Always check about the type of dust in the business. Dust is of three types: combustible, explosive, or toxic. You have to look for the dust type to be treated and cleaned.

-

Source of Dust Generation

Always check the source of dust collected and set the type of dust collector according to it.

-

Size of Particle

The size of the dust collector is required to be checked. It must be according to the equipment and filters. Always make sure the particles get filtered with a machine.

-

Air-to-cloth Ratio

Always calculate the ratio of filter area of air to cloth. It must be in a 2:1 ratio for the proper filtering process. A perfect filter allows the air to pass from the cloth and filter the dust particles from it.

-

Filtration

Always check about the filtration of dust particle size. It must be essential to understand the filtration techniques to be followed.

Client Testimonials & Reviews

AshishVerma

Enviro Instruments

TradeIndia has provided a great platform to me. It has given me a wide opportunity to sell my products in different parts of the world.A

GauravChauhan

RONAK INDUSTRIES

We are a member of tradeindia since last 4 years. We have fully satisfied for services provided by them to us and tradeindia is an excellent Portal and B2B services where buyers and supplier interact together.

Dust Collector Price List

Product Name | Expected Price |

|---|---|

| Dust Collector | 125000 |

| Id Fan | 20000 |

| Metal Cyclone Dust Collector | 45000 |

| Industrial Dust Collector | 66600 |

| Saw Dust Collector | 1000000 |

| Industrial Dust Collector | 30000 |

| Dust Collector Extractor | 40000 |

| Cartridge Dust Collector | 180000 |

| Dust Collectors | 80000 |

| Pulse Jet Dust Collectors | 95000 |

This Data was Last Updated on 2025-07-27

Dust Collector Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

United Air Tech Industries Mumbai, India | 17 Years |

Smms Engineering Systems Pvt. Ltd. Mumbai, India | 17 Years |

P-square Technologies Pune, India | 16 Years |

R+b Filter Manufacturing Enterprises Pvt. Ltd. Vadodara, India | 15 Years |

Re Blowers India Private Limited Mumbai, India | 15 Years |

Intimate Machine Tools Rajkot, India | 15 Years |

Laxmi Udyog Mumbai, India | 14 Years |

R. K. Engg. Works Pvt Ltd. Mumbai, India | 12 Years |

Success Technologies Ahmedabad, India | 11 Years |

Timus Tooling System Private Limited New Delhi, India | 10 Years |

Upcoming Tradeshows

Autoserve 2025

Thu, 09 Oct, 2025 - Sat, 11 Oct, 2025

China (Guzhen) International Lighting Fair 2025

Wed, 22 Oct, 2025 - Sat, 25 Oct, 2025

Delhi Water Expo 2025

Thu, 21 Aug, 2025 - Sat, 23 Aug, 2025

INDUS-Tech Expo 2025

Fri, 19 Dec, 2025 - Mon, 22 Dec, 2025

Aesthetic Masterclass 2025

Thu, 28 Aug, 2025 - Fri, 29 Aug, 2025

Aquatech China 2025

Wed, 05 Nov, 2025 - Fri, 07 Nov, 2025

World Food India 2025

Thu, 25 Sep, 2025 - Sun, 28 Sep, 2025

WORLD OF CONCRETE INDIA 2025

Wed, 08 Oct, 2025 - Fri, 10 Oct, 2025

Water Expo Kochi 2025

Thu, 18 Sep, 2025 - Sat, 20 Sep, 2025

INTEXT Expo 2026

Fri, 16 Jan, 2026 - Mon, 19 Jan, 2026

Popular Categories