- Tradeindia

- Raw Cotton & Cotton Waste

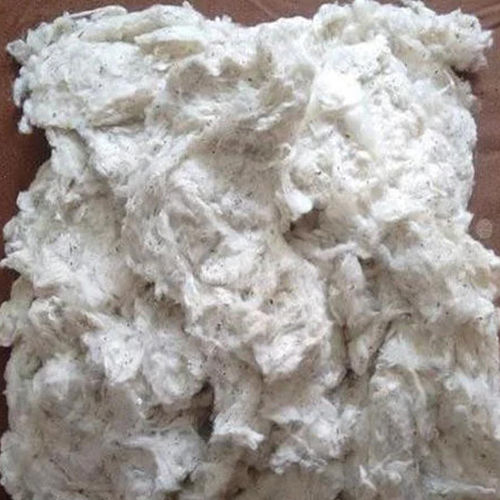

- Cotton Waste

Cotton Waste

(1083 products)Cotton Waste

Price: 45 INR/Piece

MOQ1 Unit/Units

Supply Ability10 Per Week

Delivery Time1 Days

Unique Industrials

Secunderabad

Trusted Seller

Trusted Seller9 Years

Super Seller

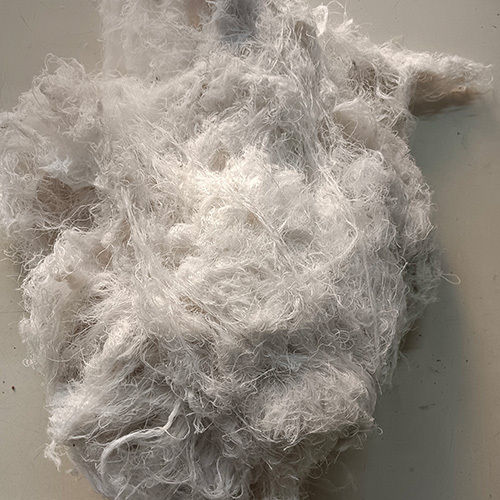

Super SellerNormal Cotton Waste

MOQ100 Kilograms/Kilograms

TypeCotton Waste

Material100% organic cotton

Cultivation TypeNormal

Optical Grade And General Purpose Grade. Pmma Cast Natural Cutoffs Pmma Waste Scrap

Price Trend: 600 - 800 USD ($)/Ton

MOQ25MT Ton/Tons

Plastic TypeOther

TypeCut Sheet

Sizeglass roofing, advertising, automotive headlamps,...

Normal Industrial Cotton Waste

MOQ100 Kilograms/Kilograms

MaterialRaw cotton

Cultivation TypeNormal

ColorOther, Multicolor

Shree Ram And Company

Pune

Trusted Seller

Trusted Seller1 Years

Premium Seller

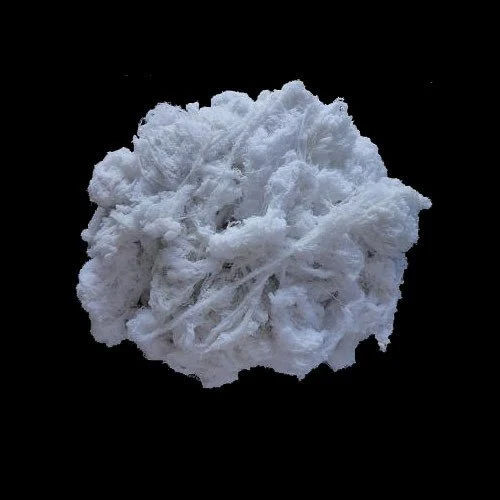

Premium SellerNitrocellulose Cotton Waste - Color: White

Price: 285 INR/Kilograms

MOQ100 Kilograms/Kilograms

TypeCotton Waste

Material100% organic cotton

Cultivation TypeOrganic

Madan Minerals And Chemicals Industries

Delhi

Trusted Seller

Trusted Seller1 Years

Premium Seller

Premium SellerPure Cotton Waste - Color: White

MOQ100 Unit/Units

TypeCotton Waste

Material100% organic cotton

Cultivation TypeNormal

Non Woven Viscose Fabric Waste

Price: 39 INR/Kilograms

MOQ1000 Kilograms/Kilograms

Product Typenon woven

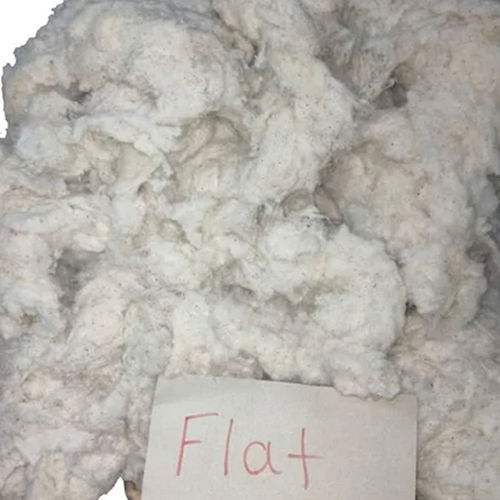

White Drooping Cotton Waste

Price: 40 INR/Kilograms

MOQ100 Kilograms/Kilograms

MaterialRaw cotton

Cultivation TypeNormal

ColorWhite

Cotton Waste - Cultivation Type: Normal

Price: 50 INR/Kilograms

MOQ500 Kilograms/Kilograms

TypePure Cotton

MaterialRaw cotton

Cultivation TypeNormal

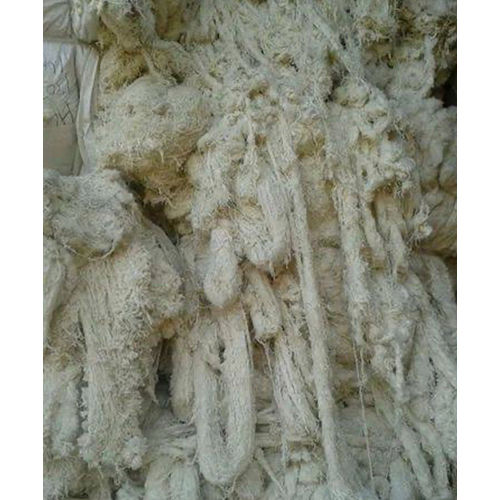

Cotton Spinning Waste

Price: /Kilograms

MOQ8000 Kilograms/Kilograms

Supply Ability1000 Per Week

Sample AvailableYes

Main Domestic MarketAll India

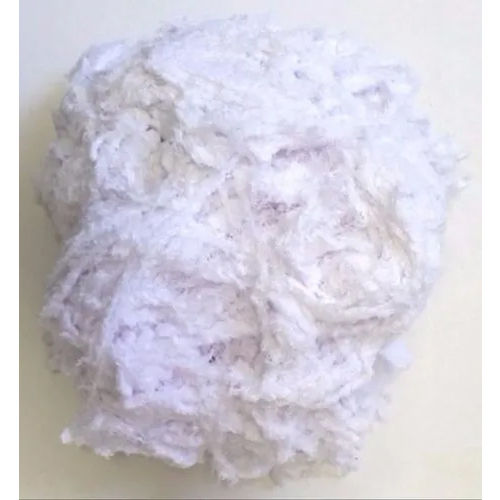

Pure Cotton Waste - Color: White

MOQ10 Kilograms/Kilograms

TypeCotton Waste

MaterialRaw cotton

Cultivation TypeNormal

100% Cotton Licker In Waste - Color: White

Price: 40.0 INR

MOQ3

TypeBales

MaterialRaw cotton

Cultivation TypeNormal

Top Rated Products

FAQs Related to Cotton Waste

Waste cotton from either the textile industry or individual consumers is used to make recycled cotton. A machine will first shred the items into smaller pieces after which they will be further processed into the crude fibre. Initially, the items will be sorted according to their kind and colour. After then, it may be remade into yarn and used in the production of entirely another item.

Cotton scraps are put to use as a raw material in the production of khadi table runners, napkins, and table cloths, as well as throws and pillow coverings. The cotton fibre that is not used in the production of cotton is where waste cotton originates.

Chlorine, poisonous dyes, pesticides, and other chemicals that are utilised in the processing of the crop into fibre and clothes may be found in the wastewater that runs off during manufacturing. These contaminants make their way into water systems such as rivers, lakes, and wetlands, as well as subterranean aquifers, and cause contamination there.

Cotton Yarn Waste - Color: White

Price: 1200 USD ($)/Metric Ton

MOQ10 Metric Ton

TypeCotton Waste

MaterialRaw cotton

Cultivation TypeNormal

COTTON WASTE

Price: 190 INR/Kilograms

MOQ50 KG Kilograms/Kilograms

FOB PortSurat

Main Domestic MarketAll India

White Cotton Waste

Price: 60 INR/Kilograms

MOQ100 Kilograms/Kilograms

TypeOther

MaterialRaw cotton

Cultivation TypeOrganic

White Recycled Pc Milange Waste

Price Trend: 60.00 - 90.00 INR/Kilograms

MOQ8000 Kilograms/Kilograms

TypeRecycled PC Milange Waste, Other

ColorWhite

Fleece Cotton Waste

Product Description\015\012 We are a renowned entity, deeply involved in offering Fleece Cotton Waste. The offered waste is broadly used in textile industry to make mats, mops, cloth wiper and other items. It is procured from

White Raw Cotton Waste

Price: 150 INR/Kilograms

MOQ1000 Kilograms/Kilograms

TypeCotton Waste

Material100% organic cotton

Cultivation TypeNormal

Cotton Waste - Recyclable Multicolor Textile Waste, Eco-friendly & Shrink-Resistant

Price: 40 INR/Kilograms

MOQ500 Kilograms/Kilograms

ColorOther, Multicolor

FeatureShrink-Resistant, Eco-friendly

Cotton Waste Merchants

Product DescriptionUnder the assistance of our professionals, we are engaged in exporting and supplying a wide spread of Cotton Waste Merchants in Mumbai, Maharashtra, India. These are manufactured using optimum grade material and cutting-edge techniques at vendor's end. Customers can avail this product from us at mar

Textile Waste

Product DescriptionWe are pleased to introduce ourselves as Exporters of different types of COTTON WASTE/ POLYESTER WASTE from Pakistan and other countries est. 1999. Our products are ideal for recycling, cleaning, filling and other purposes. Following are various varieties of Textile Waste in which we deal:\015\012\

Cotton Waste

Price: 150 INR/Ton

MOQ100 Ton/Tons

Supply Ability100 Per Day

Delivery Time1 Days

Heat-Insulation Pure White Cotton Waste

MOQ50 Kilograms/Kilograms

ColorWhite

FeatureEco-friendly, Heat-Insulation

White Cotton Waste for Textile Industry

Price: 150 INR/Kilograms

MOQ1500 Kilograms/Kilograms

TypeBales

Materialabsorbent cotton

Cultivation TypeNormal

Normal Black Cotton Waste

Price: 19 INR/Kilograms

MOQ20 Kilograms/Kilograms

TypeBlack Cotton Waste, Other

Material100% organic cotton

Cultivation TypeNormal

Denim Fiber Cotton Waste

Payment TermsLetter of Credit (L/C), Telegraphic Transfer (T/T), Others

Main Domestic MarketAll India

Mix Colour Cotton Waste Chindi For Cleaning Purpose

TypeCotton Waste

Cultivation TypeOrganic

Colormix, Other

Latest from Cotton Waste

Industrial Cotton Waste

By:

Psk Cotton Mills

Soyabean Biomass Briquettes

By:

Shibhshree Biofuels Energy Limited

Pure Cotton Waste

By:

Ask Industrial Incorporation

Cotton Waste Price List

This Data was Last Updated on 2024-12-15

Cotton Waste Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Shanmukh Trading Corporation Guntur, India | 10 Years |

Unique Industrials Secunderabad, India | 9 Years |

2lians Pte. Ltd. Singapore, Singapore | 8 Years |

Gold Plast Bhosari, India | 2 Years |

Shrikrushna Textiles Trading Company Buldana, India | 2 Years |

Shree Ram And Company Pune, India | 1 Years |

Madan Minerals And Chemicals Industries Delhi, India | 1 Years |

Ask Industrial Incorporation Vadodara, India | 1 Years |

Fine Exports Panipat, India | 1 Years |

New Tiruppur Traders Tirupur, India | 1 Years |

Upcoming Tradeshows

Gulfood 2025

Mon, 17 Feb, 2025 - Fri, 21 Feb, 2025

National Expo Raipur 2025

Sun, 19 Jan, 2025 - Wed, 22 Jan, 2025

International Crop Science Conference and Exhibition 2025

Tue, 21 Jan, 2025 - Wed, 22 Jan, 2025

LogiMAT India 2025

Thu, 13 Feb, 2025 - Sat, 15 Feb, 2025

WATER EXPO VIJAYAWADA 2025

Wed, 29 Jan, 2025 - Fri, 31 Jan, 2025

Printing South China 2025

Tue, 04 Mar, 2025 - Thu, 06 Mar, 2025

CHINA INTERNATIONAL FURNITURE FAIR 2025

Tue, 18 Mar, 2025 - Fri, 21 Mar, 2025

INDIA ART FESTIVAL 2024

Thu, 19 Dec, 2024 - Sun, 22 Dec, 2024

MachAuto 2025

Fri, 23 May, 2025 - Mon, 26 May, 2025

10th IMTOS-India Machine Tools Show 2025

Thu, 15 May, 2025 - Sun, 18 May, 2025

Popular Categories