- Tradeindia

- Building & Construction Material & Supplies

- Concrete Pavers

Concrete Pavers

(495 products)Cement Concrete Paver Block

Price: 22 INR/Square Foot

MOQ100 Square Foot/Square Foots

Thickness80 Millimeter (mm)

Moisture ContentNil

TypeDecorative Concrete Blocks

Mangilal Vijayvargiya And Sons

Indore

Trusted Seller

Trusted Seller2 Years

Super Seller

Super SellerPatio Paver Concrete Molds - Color: Multicolor

Price: 200 INR/Piece

MOQ100 , Piece/Pieces

SizeStandard

Product TypePatio Paver Concrete Molds

ColorMulticolor

Regulator Switch 2223870 - Material: Stainless Steel

Price: 27850 INR/Piece

MOQ1 Piece/Pieces

Product TypeMachine Parts

MaterialStainless Steel

TechnologyCNC

Compassion Industries Pvt. Ltd.

Pune

Trusted Seller

Trusted Seller2 Years

Super Seller

Super SellerOrange And White Concrete Blocks Pavers Plants

Price: 2900000 INR/Unit

MOQ1 Unit/Units

ColorOrange And White

General UseIndustrial

AutomaticYes

Endeavour Intelligent Equipments Pvt. Ltd.

Mehsana

Trusted Seller

Trusted Seller8 Years

Super Seller

Super SellerConcrete Paver Block

Price: 42 INR/Piece

MOQ1000 Piece/Pieces

Product DescriptionConcrete Paver Block

Mohta Cement Pvt Ltd

Indore

Trusted Seller

Trusted Seller13 Years

Premium Seller

Premium SellerSemi-Automatic Concrete Road Paver Machine

Price: 3000000 INR/Unit

MOQ1 Unit/Units

MaterialStainless Steel

ComputerizedNo

Automatic GradeSemi-Automatic

Sana Diamond Engi-mech Llp

Ahmedabad

Trusted Seller

Trusted Seller3 Years

Premium Seller

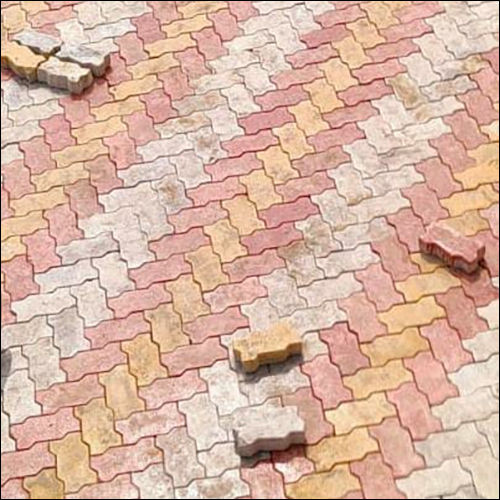

Premium SellerConcrete Paver Block

Price: 38 INR/Square Meter

MOQ100 Square Meter/Square Meters

MethodManual

MaterialConcrete

TypeInterlock Block

Concrete Vibratory Paver, Usage/Application: Road Construction Work

Product DescriptionConcrete Vibratory Paver

Poonawala Machine Tools

Mumbai

Trusted Seller

Trusted Seller4 Years

Premium Seller

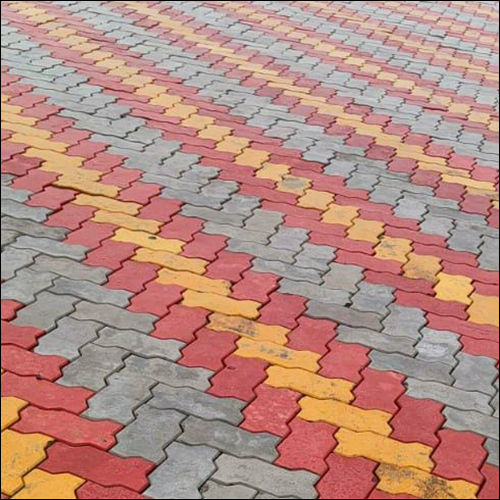

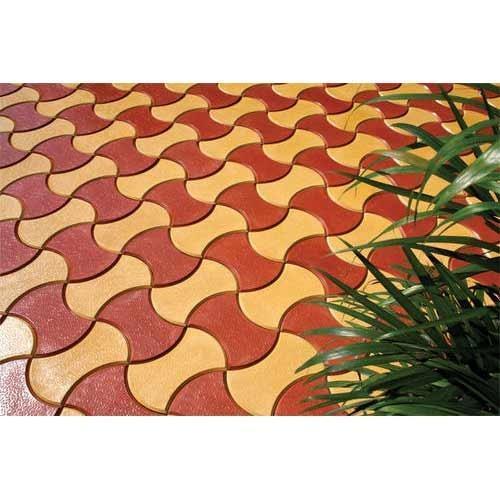

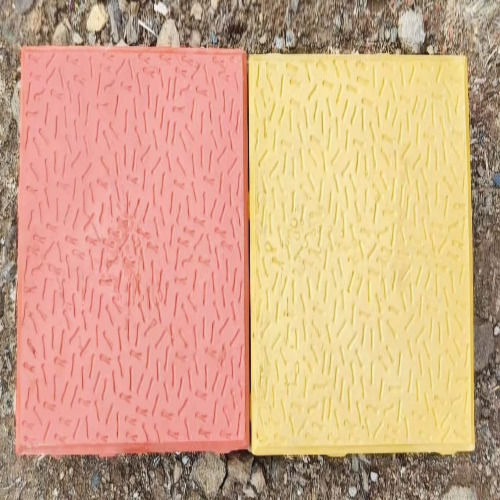

Premium SellerOrange & Yellow Road Concrete Paver Block

Price: 32 INR/Square Foot

MOQ1000 Square Foot/Square Foots

ColorOrange & Yellow

MaterialCement

Product TypePAVER BLOCK

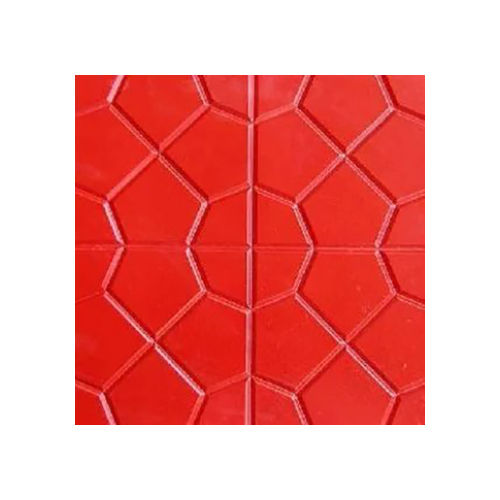

Plastic Cosmic Design Paver Moulds For Concrete

Price: 55 INR/Unit

MOQ500 Unit/Units

UsageIndustrial

MaterialPlastic

Slip Form paver

Price: 1010000 INR/Unit

MOQ1 Unit/Units

Supply Ability5 Per Day

Delivery Time2-7 Days

Main Export Market(s)Asia

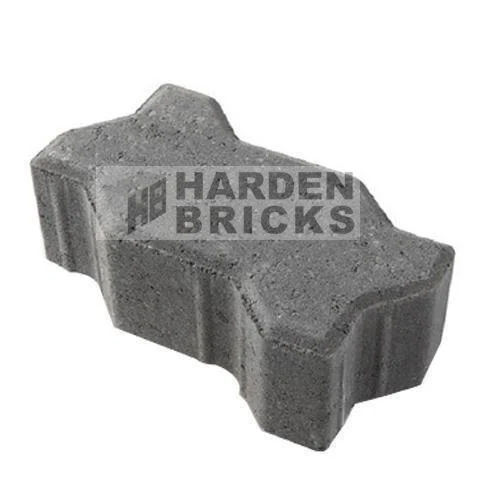

I Shape Concrete Paver Block Dry Density Grade: First Class

Price: 12 INR/Piece

MOQ2000 Piece/Pieces

Dry Density GradeFirst Class

Moisture ContentNil

MaterialCement

Top Rated Products

FAQs Related to Concrete Pavers

Follow the steps:

- Remove all sub-grade that is inappropriate, unstable, or has not been consolidated.

- An approximate depth can be calculated by adding the paver unit height, bedding sand depth, and compacted foundation material thickness.

- The recommended bedding depth for sand is 1 inch, and the sand should be clean, sharp concrete sand.

- Existing hard edges, like the side of a house, a vinyl-molded restraint, or a concrete restraint are all examples of acceptable edge restraints.

- After the paver field has been put, but just before the spot where the edge constraint will be, concrete restraints should be placed to ensure the correct height.

Grey Cement Paver Block

Price: 56 INR/Square Foot

MOQ100 , Square Foot/Square Foots

MaterialCement

MethodManual

Thickness80 Millimeter (mm)

High Strength Colored Concrete Pavers

Payment TermsCash in Advance (CID), Cheque

Sample PolicyContact us for information regarding our sample policy

Main Domestic MarketAll India

Dynamic Constructions (ss) Co Ltd.

Juba

Trusted Seller

Trusted Seller11 Years

Premium Seller

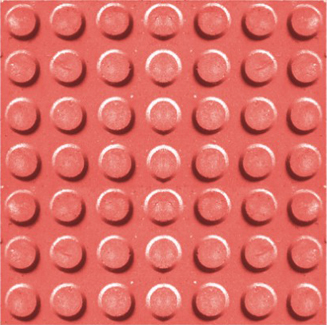

Premium SellerRed Concrete Paver Block

Price: 40 INR/Square Foot

MOQ1000 Square Foot/Square Foots

Length8 Inch (in)

Width4 Inch (in)

Thickness55 Millimeter (mm)

Behaton Paver - Color: Gray

Price: 550 INR/Square Meter

MOQ30 Square Meter/Square Meters

Compressive Strength>35 Newtons per Millimetre Squared (N/mm2)

Dimension (L*W*H)200x160x80 Millimeter (mm)

ColorGray

Semi-Automatic Fixed Form Concrete Cylinder Pavers

Price: 800000 INR/Unit

MOQ1 Unit/Units

ColorOrange

TypePavers

MaterialMS

Amruta Infratech Private Limited

Ahmedabad

Trusted Seller

Trusted Seller3 Years

Premium Seller

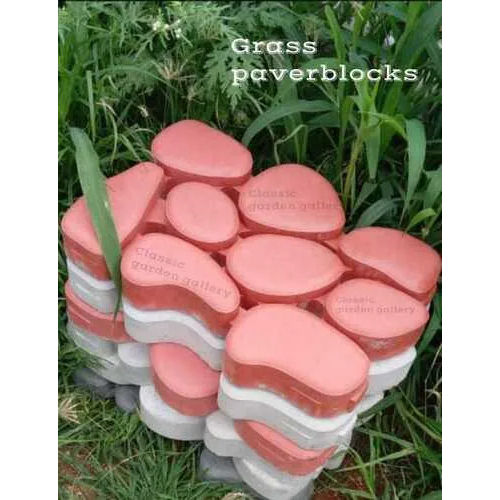

Premium SellerGrass Pavers 60 Mm - Color: White

Price: 65.0 INR/Piece

MOQ500 Square Foot/Square Foots

MaterialCement

ColorWHITE, GREY & RED

Thickness60 MM AND 80 MM Meter

Classic Garden Gallery

Hyderabad

Trusted Seller

Trusted Seller3 Years

Premium Seller

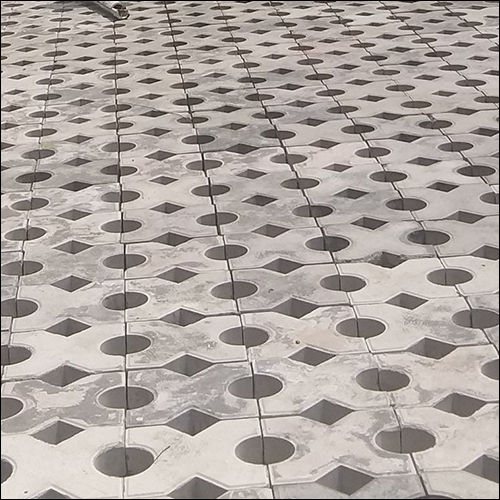

Premium SellerOctagon Flower Concrete Paver Tile Block - Color: As Per Requirement

MOQ10 Unit/Units

Frost ResistanceYes

ColorAs Per Requirement

MaterialConcrete

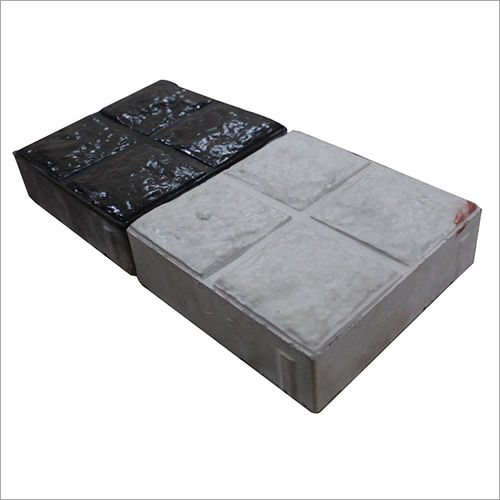

Concrete Modular Pattern Paver Block - Color: As Per Requirement

MOQ10 Square Foot/Square Foots

Moisture ContentNil

Dry Density GradeFirst Class

ColorAs Per Requirement

Red I Shape Concrete Paver Block - Color: As Per Availability

Price: 19 INR/Piece

MOQ100 Piece/Pieces

ColorAs Per Availability

TypeDecorative Concrete Blocks

Dry Density GradeHigh

Grass Concrete Paver

Price: 70 INR/Square Foot

MOQ1 , Unit/Units

Payment TermsCash Advance (CA)

Delivery Time20-40 Days

Main Domestic MarketAll India

Multicolor 60Mm Square Concrete Paver Block

Price: 28 INR/Square Foot

MOQ200 Square Foot/Square Foots

LengthDifferent Available Inch (in)

WidthDifferent Available Inch (in)

Moisture ContentNil

Paver Hardener

Product DescriptionBeing a customer centric company, we are involved in manufacturing, exporting and supplying a supreme quality range of Paver Hardeners in Ahmedabad, Gujarat, India. These products are manufactured by utilizing supreme quality raw materials and innovative technology. Furthermore, we provide this Cem

Concrete Screed Paver

Price: 850000 INR/Unit

MOQ1 , Unit/Units

Supply Ability5 Per Month

Delivery Time3 Week

Zebra Paver Mould Size: 40-80 Mm

Price: 130 INR/Kilograms

MOQ100 Kilograms/Kilograms

Product TypePaver Mould

UsageConstruction

Size40-80 mm

Latest from Concrete Pavers

Explore in hindi

ठोस पेवर्स

Introduction to Concrete Pavers

Concrete pavers are popular outdoor flooring solutions available in various shapes, colours, and sizes. These masonry products are commonly used for paving parking floors, driveways, patios, pedestrian walkways, and pool decks. They are in high demand due to their high durability and excellent resistance against harsh weather, fading, cracking, and chipping, ultimately leading to longer service life. It is easy to pave these paving blocks over floors with the help of concrete binders and adhesives to provide a personalised look for outdoor spaces. The joints between these paving blocks act as drains that allow water to seep through these joints to reduce water runoff. Concrete pavers require less maintenance and replacement which make them one of the best choices to lay floors in outdoor areas.

Types of Concrete Pavers

There is a wide variety of concrete pavers available in the market according to their shapes, sizes, and applications where they are going to be installed. Some of the popular types are mentioned below:

Interlocking Pavers

These are the most common types of paver blocks having grooved edges to ensure better fitting. They are commonly used in areas such as driveways, retaining walls, walkways, and patios to create crack-resistant solid surfaces.

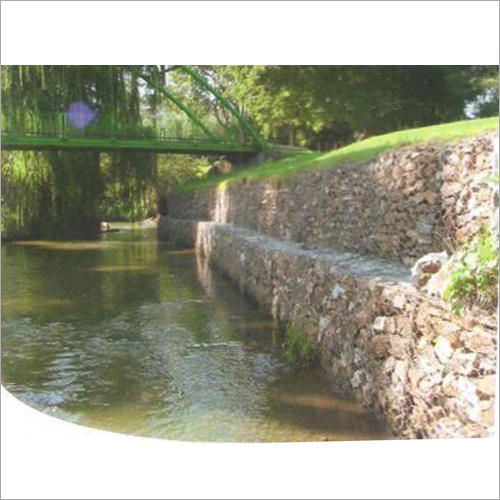

Permeable concrete Pavers

These special types of outdoor flooring blocks are designed to pass water through them to the ground. They are widely used in applications where there is a risk of water overflows such as underground parking, public parks, and driveways. These blocks are in high demand as they provide excellent protection against stormwater runoff and erosion.

Grass Pavers

These outdoor paving blocks are commonly used to make robust and aesthetic flooring over grassland. They are provided with hollow cavities in various shapes. These pavers are commonly used in gardens and public parks.

Glossy Pavers

These aesthetic stones are widely used in high-end residential and commercial landscaping applications to give a modern and rich look. They are available in various colour options provided with a shiny coat that provides high physical aesthetics.

Air Purifying Concrete Pavers

They are environment-friendly concrete blocks that are prepared by using a special type of concrete mixture which is added with titanium dioxide, which helps to remove contaminants. These blocks can be used in commercial, residential, and industrial sectors.

Applications of Concrete Pavers

Concrete pavers are highly demanding outdoor flooring solutions that can be used in industrial, residential, and commercial sectors to build highly aesthetic and durable flooring. Some of the most common areas where these paver blocks are used are mentioned below:

Pedestrian Walkways

Due to high durability and crack resistance these blocks make them suitable to create stable surfaces within streets and public parks to provide easy-to-walk-on surfaces for pedestrians.

Driveways

These heavy-duty cementitious blocks are in high demand for flooring of driveways as they are capable to withstand heavy loads of light to heavy vehicles. The excellent anti-fading properties and crack resistance make them ideal to resist abrasion due to tires.

Patios

To improve physical aesthetics and enhance the durability of the flooring of outdoor dining areas within residential or commercial sectors, concrete pavers are one of the best choices due to their high load withstanding capabilities and abrasion resistance.

Landscaping

The offered concrete pavers are available in various colour options and shapes that make them suitable for bordering gardens and other landscaping projects.

Pool Decks

The excellent slip-resistance and water seepage make them ideal for laying floors over pool decks to provide a comfortable surface to walk on. These concrete blocks also provide excellent resistance against pool chemicals.

Comparison Between Concrete Pavers and other Paving Materials

Paving blocks can be manufactured by using a variety of medium to heavy-duty materials among which concrete is one of the popular choices due to its high durability with excellent weather and abrasion resistance. Apart from concrete, there are many different types of materials such as natural stone, bricks, asphalt, wood, and plastic used for making paving blocks. All pavers in terms of material are explained below:

Natural Stones: Earth-obtained materials such as limestone, sandstone, and granite are used to make durable and water-resistant flooring pavers that are commonly used in applications where it is required to provide high physical aesthetics with robustness.

Wood: Wood pavers are physically pleasing and durable but they are expensive as compared to other options and require maintenance to prevent damage from termite and warping.

Brick: It can be considered one of the popular choices for outdoor paving applications. The brick-made paver blocks are in high demand due to their easy installation and low maintenance.

Plastic: High-density thermoplastics such as polyvinyl chloride and polypropylene are used for the making of plastic pavers that are in high demand within landscaping applications. They are in high demand among our customers due to their excellent eye-catching appearance and robustness.

Asphalt: Paver blocks made up of asphalt are commonly used to build floors in driveways, parking lots, and other high-traffic areas. These solid blocks are capable to resist impact loads and abrasion.

Tips for Choosing the Right Concrete Pavers for Your Project

It is very important to select the best concrete pavers for projects in which they are going to be used. There are several key points that you need to keep in mind before choosing paver blocks:

Durability & Strength: As paver blocks are most commonly used in outdoor applications such as walkways, driveways, pool decks, and many more, hence it is very important to use highly durable pavers that are capable to bear impact loads and provide excellent resistance against abrasion and harsh weather.

Size and Shape: It is necessary to get an accurate measure of blocks and areas where they are going to be placed, this helps to easily install them and ensure better fitting within the required space.

Texture: There are many different types of paving blocks available in the market as per the texture ranging from smooth to rough. It is important to select them for the intended use of the space.

Style and Design: Concrete pavers are available in a wide variety of colours and styles that can be used to enhance physical aesthetics within landscaping applications. They are also available in basic designs for harsh industrial areas where looks do not hold that much importance.

Price Range: Concrete paving blocks come with a wide range of prices that depends on their strength, sizes, designs, densities, and surface coating, therefore it is advisable to set your budget as per your pocket and applications where they are going to be installed.

Client Testimonials & Reviews

PrinceSingh

M.R. ENTERPRISES

Tradeindia is one of the good B2B portal in India .It's helpful to generate business.Thanks.

Mohammed

AKBERALI PRECAST PRIVATE LTD.

We are member with tradeindia.com and this platform helped us to improve our Business, Branding and Promotion. Thank you tradeindia.

Concrete Pavers Price List

This Data was Last Updated on 2024-12-14

Concrete Pavers Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Royal Tile Machines New Delhi, India | 14 Years |

Mohta Cement Pvt Ltd Indore, India | 13 Years |

Balaji Enterprises Gurugram, India | 13 Years |

Dynamic Constructions (ss) Co Ltd. Juba, South Sudan | 11 Years |

Earth Equipments New Delhi, India | 10 Years |

Endeavour Intelligent Equipments Pvt. Ltd. Mehsana, India | 8 Years |

M.r. Enterprises Ranchi, India | 6 Years |

Hiscon Industries Tikamgarh, India | 6 Years |

Kk Wires Nashik, India | 5 Years |

Poonawala Machine Tools Mumbai, India | 4 Years |

Upcoming Tradeshows

Gulfood 2025

Mon, 17 Feb, 2025 - Fri, 21 Feb, 2025

National Expo Raipur 2025

Sun, 19 Jan, 2025 - Wed, 22 Jan, 2025

International Crop Science Conference and Exhibition 2025

Tue, 21 Jan, 2025 - Wed, 22 Jan, 2025

LogiMAT India 2025

Thu, 13 Feb, 2025 - Sat, 15 Feb, 2025

WATER EXPO VIJAYAWADA 2025

Wed, 29 Jan, 2025 - Fri, 31 Jan, 2025

Printing South China 2025

Tue, 04 Mar, 2025 - Thu, 06 Mar, 2025

CHINA INTERNATIONAL FURNITURE FAIR 2025

Tue, 18 Mar, 2025 - Fri, 21 Mar, 2025

INDIA ART FESTIVAL 2024

Thu, 19 Dec, 2024 - Sun, 22 Dec, 2024

MachAuto 2025

Fri, 23 May, 2025 - Mon, 26 May, 2025

10th IMTOS-India Machine Tools Show 2025

Thu, 15 May, 2025 - Sun, 18 May, 2025

Popular Categories