- Tradeindia

- Fruit & Vegetable Processing Machine

- Coconut Cutting Machine

Coconut Cutting Machine

(105 products)Dry Coconut Cuter Machine - Automatic Grade: Semi-Automatic

Price: 12900 INR/Thousand

MOQ1 Unit/Units

ColorSilver

TypeOther

Materialstainless stel

Production Capacity40 Kg/hr

Automatic GradeSemi-Automatic

Voltage220 Volt (v)

View More

Coconut Cutting Machine - Automatic Grade: Automatic

Price : 12900 INR

Coconut Cutting Machine - Automatic Grade: Automatic

Price : 12900 INR

Tender Coconut Cutting and Punching Machine

MaterialMild Steel

Dimensions30x20x40 cm

Weight10 kg

PowerNA

VoltageNA

Blade MaterialStainless Steel

Yes Square Marketing

Coimbatore

Trusted Seller

Trusted Seller Super Seller

Super Seller Premium Seller

Premium Seller7 Years

View More

Tender Coconut Cutting and Punching Machine SS

Price : 17,500 INR

Ms Tender Coconut Cutting Machine - Application: Industrial

Price : 8500.0 INR

Coconut Cutting Machine Hp 2 - Capacity: 70-80 Kg/Hr

Price: 18400 INR/Piece

MOQ1 Piece/Pieces

Product TypeCoconut Cutting Machine HP 2

General UseIndustrial

MaterialSteel

Capacity70-80 Kg/hr

ComputerizedNo

Drive TypeElectric

Shreeja Health Care Products

Surat

Trusted Seller

Trusted Seller Super Seller

Super Seller9 Years

View More

Coconut Cutting Machine Hp 1 - Capacity: 30-40 Kg/Hr

Price : 10700 INR

Low Noice Commercial Automatic Copra Cutter

Price: 11000 INR/Piece

MOQ1 Piece/Pieces

General UseCutting coconut, chilli, onion etc..

MaterialStainless Steel

Voltage110-415 Volt (v)

Power1 to 2 Horsepower (HP)

FeatureECO Friendly, Low Noice, Lower Energy Consumption, High Efficiency

Warranty- One year against manufacturing defects at our site, except all wear and tear parts.

Steel Coconut Scraper Deluxe

Price: 100 INR/Piece

MOQ1 Piece/Pieces

ColorSteel

Product TypeScrapper

MaterialMetal

Metal TypeStainless Steel

Plastic TypeOther

Sizeas per product

Apex Homeneeds Pvt. Ltd.

Rajkot

Trusted Seller

Trusted Seller Premium Seller

Premium Seller11 Years

Industrial Coconut Shelling Peeling Cutting Washing Drying Machine

Product Capacity300-700 Kg/h

Voltage220/380 Volt (v)

Power Type0.5 - 0.75 KW

ColorSilver

ApplicationIndustrial

Zhaoqing Fengxiang Food Machinery Co., Ltd.

Guangdong

Trusted Seller

Trusted Seller Premium Seller

Premium Seller3 Years

View More

Coconut Crusher Chopping And Cutting Machine - Color: White

Price : 1545 USD ($)

Fc-305 Automatic Coconut Cutting Machine Coconut Slicing Machine Capacity: 500 Kg/Hr

Price : 1000.00 USD ($)

Copra Cutter

MaterialHardened Steel

Capacity10-50 TPD

DimensionsVariable

Motor PowerVariable

Blade TypeRotating

UsageCopra processing and oil extraction

Shree Balaji Agro Industries

Ludhiana

Trusted Seller

Trusted Seller Premium Seller

Premium Seller3 Years

ARS Engineering Coconut Cutting Machine - Stainless Steel, 1000 Pcs/hr Capacity, Stylish Blue Color | Automatic Food Processor with 1-Year Warranty

Price: 110000.0 INR/Set

MOQ1 Set

ColorBlue

MaterialStainless Steel

TypeFood Processors

Automatic GradeSemi-Automatic

Capacity1000 Pcs/hr

Control SystemHuman Machine Interface

Modular Coconut Crusher - Stainless Steel, Various Sizes Available, Sleek Silver Finish - Effortlessly Breaks Down Tough Coconuts

Price: 6200 INR/Unit

MOQ1 Unit/Units

ColorSilver

MaterialMetal

SizeDifferent available

Metal TypeStainless Steel

Surface FinishPlain

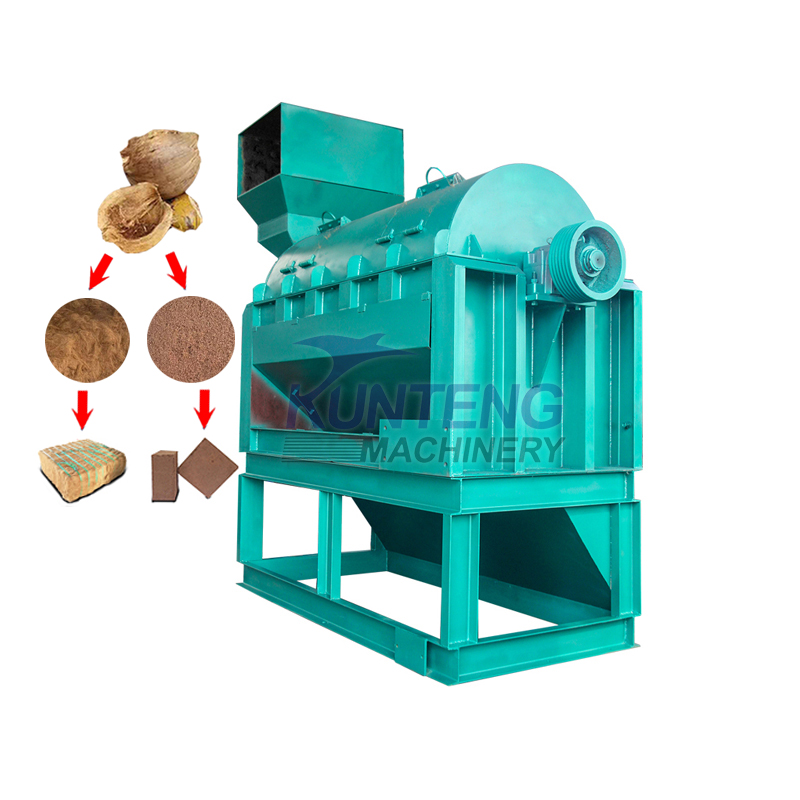

Coconut Shell Fiber Extraction Machine,Coconut Shell Fiber Making Machine - Color: Customized

Price: 446969 INR/Piece

MOQ1 Piece/Pieces, Piece/Pieces, Unit/Units

Product TypeCoconut shell fiber extraction machine

General UseCoconut shell fiber extraction

TypeCoir Fiber Extractor

Weight (kg)5000 Kilograms (kg)

ComputerizedYes

AutomaticYes

Henan Kunteng Machinery Manufacturing Co., Ltd

Zhengzhou

Trusted Seller

Trusted Seller1 Years

Chips And Coconut Lacchha Cutting Machine - Color: Silver

Price: 22800.0 INR/Unit

MOQ1 Unit/Units

ColorSilver

General UseIndustrial

MaterialOther, Stainless steel

TypeAutomatic Cutting Machine

ComputerizedNo

AutomaticYes

Coconut Cutter Machine - Color: Silver

Price: 15500.00 INR/Unit

MOQ1 Unit/Units

ColorSilver

Product TypeRaw Coconut Cutting Machine

General UseIndustrial

MaterialAluminum

ComputerizedNo

AutomaticNo

FAQs Related to Coconut Cutting Machine

Tender Coconut Cutting Machine - Stainless Steel, Blue | Easy Maintenance, Very Long Life Blade, Safe Operation

MOQ1 Piece/Pieces

Product TypeTENDER COCONUT CUTTING MACHINE

MaterialStainless Steel

AutomaticNo

ColorBlue

Cocoa Processing Plant - General Use: Restaurant

MaterialStainless Steel

Capacity1000 Liters

Power3 Phase

Voltage415V

Dimensions2.5m x 1.5m x 1m

Weight1000kg

Coconut Crusher Machine - Automation Grade: Automatic

Price: 60000 INR/Unit

MOQ1 Unit/Units

FeaturesHigh Quality

Automation GradeAutomatic

Operating TemperatureAs per industry standard Celsius (oC)

MaterialStainless Steel

AutomaticYes

Installation TypeFree Stand

Dry Cutting Coconut - Color: Brown

Price: 290000 INR/Ton

MOQ10 Ton/Tons

ColorBrown

StyleDried

Cultivation TypeOrganic

SizeDifferent available

Weight (kg)As per requirement Kilograms (kg)

Coconut Husk Chips Cutting Machine With Beater With Motor - Capacity: 300 Kg/Hr

Price: 150000.0 INR/Unit

MOQ1 Unit/Units

General UseAgriculture

MaterialOther

Capacity300 Kg/hr

ComputerizedNo

AutomaticNo

Control SystemPLC Control

View More

Coconut Husk Chips Cutting Machine

Price : 150000 INR

Coconut Husk Chips Cutting Machine - Feature: Good Quality

Price : 40500.0 INR

Coconut Husk Cutting Machine

Price : 40500 INR

Coconut Husk Chips Cutting Machine 4 Blade With Motor - Dimension (L*W*H): 1300X610X1300 Millimeter (Mm)

Price : 45000.0 INR

Coconut Husk Cutting Machine With Motor - Capacity: 200-400 Kg/Hr

Price : 40500 INR

Jarkan Cutting Machine - General Use: Industrial

Price: 160000 INR/Piece

MOQ1 Piece/Pieces

General UseIndustrial

MaterialSteel

TypeAutomatic Cutting Machine

ComputerizedNo

AutomaticNo

Control SystemPLC Control

Coconut Cutting Machine - Color: Green

Price: 9600 INR/Unit

MOQ5 Unit/Units

ColorGreen

Product TypeCoconut Cutter

MaterialStainless Steel

Weight (kg)10 Kilograms (kg)

Dimension (L*W*H)60X80X90 Millimeter (mm)

Warranty1

Coconut Cutting Machine - Application: Small Scal Industries

Price: 97000.0 INR/Piece

MOQ1 Piece/Pieces

Phase3

Processing TypeCUTTING SINGEL SIDE MACHINE

Machine TypeAutomatic

Length900 Millimeter (mm)

Weight200 Kilograms (kg)

Power TypeELECTRICAL

Industrial Coconut Cutting Machine - Feature: Low Energy Consumption

Price: 155000.00 INR/Piece

MOQ1 Piece/Pieces

Product TypeCoconut Cutting Machine

General UseIndustrial

MaterialOther, Mild Steel & Stainless Steel

AutomaticYes

Control SystemManual

Cutting FunctionSemi Automatic

View More

Semi Automatic Coconut Trimming Machine - Color: Blue

Price : 95000.00 INR

Industrial Coconut Tail Removing Machine - Color: Blue

Price : 148000.00 INR

Copra Coconut Cutting Machine - Application: Industrial

MOQ1 Unit/Units

Voltage220-440 Volt (v)

FeatureStable performance

ApplicationIndustrial

OriginIndia

Power TypeElectric

Pasaydan Engineering & Food Processing Technology Private Limited

Pune

Trusted Seller

Trusted Seller1 Years

Coconut Pre Cutting Machine - Running Speed: 1440 Rpm

Price: 12660 INR/Piece

MOQ1 Piece/Pieces

Use Type1

Running Speed1440 RPM

ApplicationCoconut Cutting

Voltage220 Volt (v)

Product Capacity200 Coconuts Per Hour

Warranty1 Year

Coconut Powder Making Machine

MaterialStainless steel

Power1-3 HP

Capacity50-100 kg/hr

Dimensions1000x800x1500 mm

Weight150-200 kg

Voltage220-440V

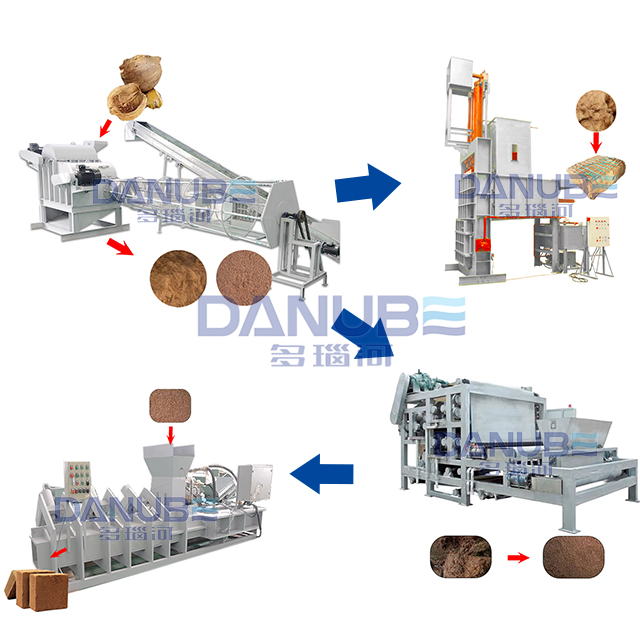

Coconut Shell Processing Equipment Coconut Cutting Machine - Color: Customized

Price: 1685313 INR/Unit

MOQ1 Unit/Units

Processing TypeCoconut Husk Processing Line

Height2700 Millimeter (mm)

ApplicationExtracting coir fiber from coconut husk

FeatureOverseas Service Provided

Power TypeElectric or Diesel Engine

Production Output4000 Pieces/Hour

Dry Coconut Crusher Machine In Mumbai Bharat Machinery Spares

Price: 180000 INR/Piece

MOQ1 Piece/Pieces

Product Capacity800 Coconuts/Hr

ApplicationCommercial

Coconut Pre Cutter

Price: 450000 INR/Piece

MOQ1 Piece/Pieces

ColorOther, Silver

Automation GradeAutomatic

Product TypeCoconut pre cutter

MaterialStainless Steel

AutomaticYes

Voltage220 Volt (v)

Automatic Coconut Copra Cutting Machine - Application: Industrial

Price: 14000 INR/Unit

MOQ3 Unit/Units

Voltage220 Volt (v)

ApplicationIndustrial

ColorSilver

Use TypeCommercial

Power TypeElectric

Warranty1 Year

Popular Coconut Cutting Machine

Coconut Cutting Machine a Introduction

Types of Coconut Cutting Machine

Features and Specifications for the Coconut Cutting Machine

Advantages of Coconut Cutting Machine

Coconut Cutting Machine Price List

This Data was Last Updated on 2025-12-30

Coconut Cutting Machine Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Jas Enterprise Ahmedabad, India | 21 Years |

New Bhavna Machine Tools Vadodara, India | 12 Years |

Apex Homeneeds Pvt. Ltd. Rajkot, India | 11 Years |

Shreeja Health Care Products Surat, India | 9 Years |

Yes Square Marketing Coimbatore, India | 7 Years |

Mariya Engineering Works Coimbatore, India | 7 Years |

Vivan Global Impex Surat, India | 6 Years |

New Tech Industries Mangaluru, India | 6 Years |

Zigma Machinery & Equipment Solutions Coimbatore, India | 6 Years |

Novo3d Coimbatore, India | 5 Years |

Upcoming Tradeshows

CWIEME Shanghai 2026

Wed, 24 Jun, 2026 - Fri, 26 Jun, 2026

AMR - Auto Maintenance and Repair Expo 2026

Mon, 13 Apr, 2026 - Wed, 15 Apr, 2026

Asia Photonics Expo (APE 2026)

Wed, 04 Feb, 2026 - Fri, 06 Feb, 2026

IFF - India Fashion Forum 2026

Wed, 28 Jan, 2026 - Thu, 29 Jan, 2026

Plastic Packaging Printing Expo (P3) 2026

Fri, 10 Apr, 2026 - Mon, 13 Apr, 2026

STEEL CONSTRUCTION EXPO 2026

Thu, 26 Feb, 2026 - Sat, 28 Feb, 2026

Water Expo Guwahati 2026

Thu, 12 Mar, 2026 - Sat, 14 Mar, 2026

IMTOF 2026 INTERNATIONAL MACHINE TOOLS EXHIBITION

Thu, 02 Apr, 2026 - Mon, 06 Apr, 2026

Spectra Expo 2026

Wed, 06 May, 2026 - Fri, 08 May, 2026

Odisha Mining & Infrastructure International Expo 2026

Thu, 08 Jan, 2026 - Sun, 11 Jan, 2026

Popular Categories