- Tradeindia

- Automotive Parts & Components

- Automotive Sleeves

Automotive Sleeves

(113 products)Silver Oem Sleeve For Automobile Bearing Sleeve

Price: 0.58 USD ($)/Piece

MOQ500 Piece/Pieces

Product TypeAutomotive Sleeves

UsageIndustrial

ColorSilver

Cixi Hoto Metallic Product Co.,ltd

Ningbo

Super Bonanza

Super Bonanza Trusted Seller

Trusted Seller10 Years

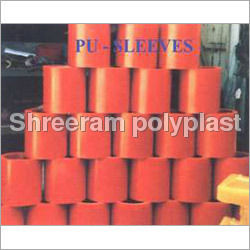

Polyurethane Sleeves

Price Trend: 5000.00 - 25000.00 INR/Piece

MOQ100 Piece/Pieces

Supply Ability1000 Per Month

Delivery Time2-3 Days

Sample AvailableYes

Bike Rubber Lever Sleeve Vehicle Type: Two Wheeler

Price: 5 INR/Pair

MOQ100 Pair/Pairs

Product TypeOther, Bike Lever Sleeve

MaterialRubber

Vehicle TypeTwo Wheeler

Withdrawl Sleeves

Price: 100 INR/Piece

MOQ100 Piece/Pieces

Supply Ability100 Per Day

Delivery Time3 Days

ASSY.CONTROL VALVE SLEEVE TYPE REPLACES

Product DescriptionASSY.CONTROL VALVE SLEEVE TYPE REPLACES

Automobile Sleeves

Product DescriptionM/s. Ganesh Loco Components An ISO 9000 company the parent company of M/s. Ganesh Loco Components Private Limited was incepted in the year 1977 for the production of Railway Engine Components, Railway Diesel Engine Components, Electric Loco Motive Components.\015\012\015\012In 1994 M/s. Ganesh Loc

Incoloy 925 Sleeve Application: Steel Making

Price: 145 INR/Piece

MOQ10 Piece/Pieces

Purity95%

HardnessSot

Product TypeMetal

Blue 1200A 800A 810Mm Flc Foldable Large Pallet Box

ColorBLUE

Product Type1200A--800A--810mm FLC Foldable Large Pallet Box

MaterialPLC

Top Rated Products

FAQs Related to Automotive Sleeves

Who are the top automotive sleeves manufacturers in India?

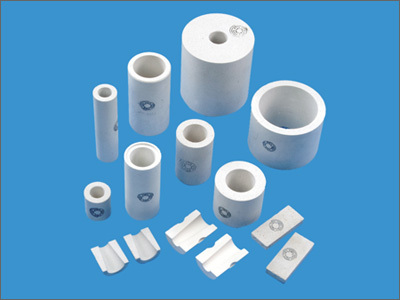

- Ceraflux India Pvt Ltd

- Ganesh Loco Components Private Ltd

- Premier Auto Cables

- Shreeram Polyplast

- Indus Marketing Engineers

- Cixi Hoto Metallic Product Co.,ltd

- Beekay Automotives

- Lal-g Accessories

- Subina Exports

- Balwinder Mechanical Works

Which cities have the largest number of automotive sleeves suppliers?

- Delhi

- Pune

- Mumbai

- Chennai

- Bengaluru

- Kolkata

- Jaipur

- Ludhiana

- Faridabad

- Rajkot

- Jamnagar

- Gurugram

- Ahmedabad

- Ghaziabad

- Sonipat

- Palghar

- Noida

- Coimbatore

- Howrah

- Kolhapur

What is the price range for automotive sleeves offered by listed companies?

| Company Name | Currency | Product Name | Price |

|---|---|---|---|

| S D ENTERPRISES | INR | Deep Groove Structure Automobile Segment Sleeve | 1 |

| Prema Engg Works | INR | Mild Steel Threaded Sleeve For Automobiles Use | 0.1 |

| ELMEC TOOLS & DEVICES PVT. LTD. | INR | 25 Mm Polish Finish Stainless Steel Automotive Sleeves | 200 |

| TATA PRECISION INDUSTRIES INDIA LIMITED | INR | Automobile Sleeve | 800 |

How many trusted sellers are available for automotive sleeves?

- CIXI HOTO METALLIC PRODUCT CO.,LTD

- BEEKAY AUTOMOTIVES

- PREMIER AUTO CABLES

- GANESH LOCO COMPONENTS PRIVATE LTD

What is the minimum order quantity for automotive sleeves?

Do listed companies have registration & certifications?

- GANESH LOCO COMPONENTS PRIVATE LTD

- GANESH INDUSTRIES

- MONIKA PLASTIC

- Luoyang Lever Industry Co., Ltd.

- SONU TRADING COMPANY

- KUMAR CERAMICS PVT. LTD.

- AS ENTERPRISES

- CLASSIC EXPORTS

What is the get latest price feature?

What types of payment methods are accepted by the automotive sleeves suppliers?

Automotive Sleeves

Product DescriptionOur firm indulged in manufacturing and supplying a vast array of Automotive Sleeves, which is made with supreme grade material that is sourced from most authentic vendors of the market. It is offered in various forms, in order to cater to the diverse demands of customers. Offered with us at most rea

Piston Sleeve

Price: 1500 INR/Piece

MOQ50 Piece/Pieces

Supply Ability1000 Per Day

Delivery Time1 Week

Automotive Sleeve

Price: 450 INR/Piece

MOQ100 Piece/Pieces,

Product DescriptionAutomotive Sleeve

Deep Groove Structure Automobile Segment Sleeve

Price: 1 INR/Piece

MOQ5000 Piece/Pieces

Product TypeSegment Sleeve

FinishPolished

ColorGrey

Silver 25 Mm Polish Finish Stainless Steel Automotive Sleeves

Price: 200 INR/Kilograms

MOQ400 Kilograms/Kilograms

ColorSilver

Product TypeAutomotive Sleeves

MethodMachine Made

Steel Automotive Control Cable Inner Coating Wire

Price: 8 INR/Meter

MOQ100 Meter/Meters

Product TypeOther, Cable Inner

MaterialSteel

TypeGalvanized

GSS Sleeve Assembly

Price: 800 INR/Piece

MOQ100 Piece/Pieces

For Use InCars

MaterialSteel

FinishPolished

Yellow Aramid Fiber Kevlar Rope & Sleeves For Glass Tempering Furnace

Price Trend: 1.90 - 4.50 USD ($)/, Roll

MOQ1 , Roll/Rolls

Product TypeMachine Accessories

Material100% Para Aramid

ColorYellow

Painted H-Class Sleeve

Price: 91 INR/Sheet

MOQ1 Sheet/Sheets

Product TypeOther, H-Class Sleeve

MaterialOther, Silicone Rubber

Surface FinishPainted

Ceramic Alumina Sleeves

Price: 7.00 INR/Piece

MOQ100 Piece/Pieces

Supply Ability500-10000 Per Day

Delivery Time7-10 Days

Sample AvailableYes

Cast Iron Sleeves

Product DescriptionCast Iron Sleeves With the help of our manufacturing unit and experienced personnel, our company brings forth an exclusive range of Cast Iron Sleeves .By offering premium quality machines in the market, we have emerged as one of the most favored choice in terms of leading manufacturers and expor

Mild Steel Threaded Sleeve For Automobiles Use

Price: 0.10 INR/Piece

MOQ5000 Piece/Pieces

Colorgrey

Surface TreatmentPowder Coated

Materialmild steel

MRT Automate Master Sleeve

MOQ40 Piece/Pieces

Payment TermsCash on Delivery (COD), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Delivery Point (DP), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Days after Acceptance (DA), Cash in Advance (CID), Cash Advance (CA)

Sample AvailableYes

Sample PolicyContact us for information regarding our sample policy

Automobile Sleeves

Product DescriptionFor the diverse industrial requirements, we are involved in manufacturing, exporting and supplying the finest quality array of Automobile Sleeves. These products are used in various automobile industries for their reliability. The provided products are used in tractors, diesel engine and in various

Automotive Sleeves

Product DescriptionFind here adjustable tie-rod sleeves, Moog tie rod sleeves, TRW sleeves, Dana Spicer tie rod sleeves, and AC Delco tie rod sleeves. Providing superior performance, quality, accuracy and precision, these automotive sleeves are highly recommended to be used in AM & Chrysler Jeep, Chrysler Truck, Chevr

Latest from Automotive Sleeves

Sleeve Gear

By:

Auto Gear (india)

Optimum Quality Automotive Sleeves

By:

Rototech Metal & Auto Co.

Automotive Sleeves

By:

Test Auto Parts

Automobile Sleeve Shafts

By:

Jrb Engineering Works

Sleeve Yoke

By:

Jaypee Power Transmission

Automotive Sleeves

By:

Ganesh Industries

Automotive Sleeves

By:

Veltech Engineering Works

Explore More Cities

Explore in hindi

मोटर वाहन आस्तीन

Automotive sleeves are basically cylindrical parts that are fitted into an engine block for the purpose of either forming a cylinder or for repairing of damaged cylinder bores. The sleeves generally are much harder compared to engine blocks and so are ideal for housing the piston, since the hardness of the sleeves prevents the piston from wearing through the cylinder bore. These sleeves are commonly used in almost all diesel engines and also are an absolute necessity in engine blocks made from aluminum, since aluminum engine blocks are too soft for containing a piston.

Automotive sleeves are also called as automotive liners, with either of the two names being used in different parts of the world. In japan, these are called as automotive liners, while in other parts of the world like the united states or countries in Europe, these are generally called as automotive sleeves. The sleeves are available in a wide assortment of dimensions, finishing options etc. Furthermore, the sleeves can also be customized according to a specific requirement.

Prerequisites for Automotive Sleeves

An ideal automotive sleeve should have the following attributes.

It should be dimensionally accurate

The sleeve must be manufactured to exacting tolerance for proper fitting

It must be able to withstand high level of hoop stress

Should also withstand high thermal stress

An automotive sleeve should be resistant to corrosion and wear

The sleeve should also have optimal porosity

Construction of Automotive Sleeves

The construction of automotive sleeves is done either by centrifugal casting or sand casting process. Centrifugal casting process is used for making small sleeves, while sand casting is ideal for larger automotive sleeves. The inner surface of the sleeves is generally chrome plated to make it smooth, however, recent drawbacks have been found in this design such as this design does not allow the oil to spread out properly, thus affecting lubrication. To rectify the aforementioned drawback, the use of porous chrome honing is gradually being increasingly preferred by sleeve manufacturers.

As for materials used in construction, cast iron alloyed with small quantities of nickel , copper, chromium etc. is preferred. The alloying here is almost always of the order of 5 percent.

Installation of Automotive Sleeves

The automobile's cylinder first must be stripped of all removable parts such as studs, bolts, nuts etc.

After measuring the outside diameter of the sleeve, the cylinder is bored out accordingly.

The cylinder is then heated in a temperature of 400-450 degrees Celsius for an hour.

Afterwards, the sleeve automatically drops easily into the cylinder, with a needle nose type device used for ensuring optimal fit.

The cylinder is then put under a hydraulic press to keep the sleeve from rising while the cylinder cools.

After cooling, the automotive sleeve must be bored out and honed to ensure proper piston clearance.

Client Testimonials & Reviews

MrJ.D.PATEL

BHAVANI AUTO INDUSTRIES

I am using tradeindia platform from last so many years and I am getting a good response and I have expanded my business so for that again I have chosen tradeindia. I couldn't find any other B2B better than tradeindia. Hope we can build a long term business together.

ManishKolhatkar

M TEK ENGINEERS

The services offered by GetDistributors.com have been crucial to our development and success, and I am keen to keep up our profitable commercial relationship. GetDistributors.com is a website that I heartily endorse to other businesses seeking to grow in their industry. It serves as a portal for a wealth of opportunities and connections that can take your company to new heights.

DavinderSandhu

SANDHU AUTO ENGINEERS

We are the leading manufacturers and suppliers of Automotive components,fastners and Pole Line Hardware and have approved the service rendered by tradeindia.com for our brands good promotion in Domestic as well as in International markets. We are getting more and more coverage in this Global World through their services and many more. We are proud to be associated since last Three years with them and we are totally satisfied with their services. Also their CRM Support given by them regularly. We are thankful for the support and hope it will continue years after years. Best Luck.

DineshSharma

D. S. AUTO

It is to certify that M/s D.S.Auto is associated with Trade India for last three years and we are getting our promotion in a very positive aspect.

LokeshJain

BST AUTO PVT. LTD.

I attached with Infocom Network Limited for five years. I got good & serious enquiry from Trade India. I am happy with Infocom & its executive Mr. Ashok Sarna who gave me the best services.

Automotive Sleeves Price List

This Data was Last Updated on 2024-12-14

Automotive Sleeves Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Ceraflux India Pvt Ltd Kolhapur, India | 17 Years |

Ganesh Loco Components Private Ltd Jodhpur, India | 17 Years |

Premier Auto Cables Lucknow, India | 16 Years |

Shreeram Polyplast Chennai, India | 11 Years |

Indus Marketing Engineers Mumbai, India | 11 Years |

Cixi Hoto Metallic Product Co.,ltd Ningbo, China | 10 Years |

Beekay Automotives Delhi, India | 10 Years |

Lal-g Accessories New Delhi, India | 6 Years |

Subina Exports Delhi, India | 6 Years |

Balwinder Mechanical Works Ludhiana, India | 6 Years |

Upcoming Tradeshows

Gulfood 2025

Mon, 17 Feb, 2025 - Fri, 21 Feb, 2025

National Expo Raipur 2025

Sun, 19 Jan, 2025 - Wed, 22 Jan, 2025

International Crop Science Conference and Exhibition 2025

Tue, 21 Jan, 2025 - Wed, 22 Jan, 2025

LogiMAT India 2025

Thu, 13 Feb, 2025 - Sat, 15 Feb, 2025

WATER EXPO VIJAYAWADA 2025

Wed, 29 Jan, 2025 - Fri, 31 Jan, 2025

Printing South China 2025

Tue, 04 Mar, 2025 - Thu, 06 Mar, 2025

CHINA INTERNATIONAL FURNITURE FAIR 2025

Tue, 18 Mar, 2025 - Fri, 21 Mar, 2025

INDIA ART FESTIVAL 2024

Thu, 19 Dec, 2024 - Sun, 22 Dec, 2024

MachAuto 2025

Fri, 23 May, 2025 - Mon, 26 May, 2025

10th IMTOS-India Machine Tools Show 2025

Thu, 15 May, 2025 - Sun, 18 May, 2025

Popular Categories