- Tradeindia

- Cnc Machines

- Aluminium Profile Cutting Machine

Aluminium Profile Cutting Machine

(86 products)Blue Je 350Ha High Speed Semi Automatic Aluminum Cutting Machine

Price: 285000 INR/Unit

MOQ1 Unit/Units

ColorBlue

Product TypePipe Cutting Machine

General UseCutting

MaterialAluminum

TypeAutomatic Cutting Machine

Weight (kg)360 Kilograms (kg)

Aluminium Section Cutting Machine

Dimension6000x1500x2000 (LxWxH)

Weight1550 kg

MaterialSteel

BladeHigh-speed steel

Motor3-phase

Power5.5 kW

Zenith Engineering And Equipments Private Limited

Vadodara

Trusted Seller

Trusted Seller Premium Seller

Premium Seller11 Years

View More

Heat Sink Aluminum Profile Cutting Machine

Get Best Deal

Gray Aluminium Profile Cutting Machine By Zenith Engineering and Equipments Private Limited

Price : 285000 INR

Aluminium Profile Cutting Machine - Premium Grade Material, High Precision Cutting , Durable Design

Price : 285000 INR

Single Head UPVC Cutting Machine - Aluminum & Plastic Profiles, 700x700x1400mm, Gray, 420mm Blade, 3HP, 2800 RPM Cutting Speed, Automatic Feeding, Low Noise

Price Trend : 200000.00 - 550000.00 INR

CNC Profile Cutting Machine - Aluminum & UPVC, 4950x1100x1550 mm Dimensions | 2.2 KV Motor Power, 450 mm Max Cutter Diameter, 1 Year Warranty, Environmental Friendly

Price : 650000.00 INR

Heat Sink Aluminum Profile Cutting Machine - Color: Gray

Price : 400000 INR

SCHUCO FOM BLITZ XZ 10094 - 440W Semi Automatic CNC Cutting Machine | Used Aluminium Profile Cutting 45-90 Degrees, Painted Finish

Price: 700000.00 INR/Unit

MOQ1 Unit/Units

Product TypeCutting Machine

TechnologyCNC

Power SourceElectricity

Operating TypeSemi Automatic

Power440 Volt (v)

Surface TreatmentPainted

Automatic Solar Frame Cutting Machine - 350/400mm TCT Blade, 5190x1320x1620mm, Blue, 2x1.5kW Motor Power | Hydro-Pneumatic Feed, PLC Control, Ethernet HMI

Price: 850000.0 INR/Piece

MOQ1 Piece/Pieces

ColorBlue

Product TypePvc & Aluminum Cutting Machine

General UseFor Doors & Windows Making

Weight (kg)550 Kilograms (kg)

AutomaticYes

Control SystemPLC Control

Taalin Machinery & Robotics Pvt. Ltd.

Greater Noida

Trusted Seller

Trusted Seller Premium Seller

Premium Seller5 Years

View More

Manual Double Head Cutting Machine 420Mm For Aluminum Profile - Color: Blue

Price : 550000.0 INR

Aluminium Profile Cutting Machine - Color: Blue

Price : 295000.0 INR

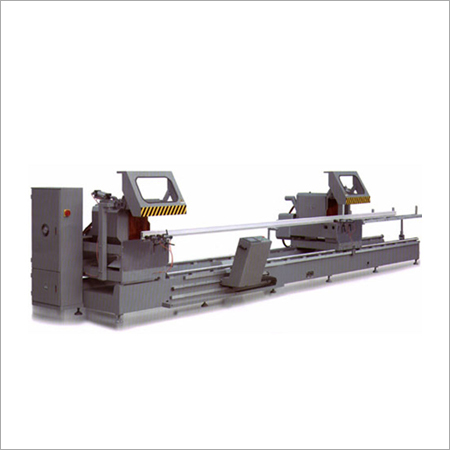

Double Head Cutting Machine For Aluminium Profile - Feature: Good Quality

Price : 850000.0 INR

Portable Cnc Profile Cutting Machine - Automatic Grade: Semi-Automatic

Price: 125000.00 INR/Unit

MOQ1 Unit/Units

MaterialStainless Steel

ComputerizedNo

Automatic GradeSemi-Automatic

Control SystemFrequency Speed Control

Cutting FunctionSemi Automatic

Drive TypeElectric

45 Degree Thermal Break Profile Cutting Machine - Dimension 5900x1870x1390mm, 900KG Weight | 2 Cutting Blades, High Efficiency, Semi-Automatic Operation

MOQone Piece/Pieces

Product TypeKT-363F

TypeMetal Cutting Machine

Weight (kg)900 Kilograms (kg)

ComputerizedNo

AutomaticNo

Cutting FunctionSemi Automatic

Foshan Shunde Kingtool Aluminum Processing Machinery Co., Ltd.

Foshan

Trusted Seller

Trusted Seller14 Years

View More

45 Degree Angle Double Head Cutting Machine - Aluminum Profile Cutting , 550mm Blade Size, 3KW High-Efficiency Motors, Precise Length Adjustment 430-4500mm

Price : 13500 USD ($)

Automatic Aluminum And Upvc Door Cutting Machine - Feature: Good Quality

MaterialMild Steel

Power2.2 KW

Cutting Capacity120mm

Cutting Angle45°

Dimensions1200 x 1000 x 1500 mm

Weight500 kg

Aluminium Profile Cutting Machine - Steel Build, 220-240V Electric Drive | Automatic Operation, Good Quality, 1 Year Warranty

MaterialSteel

Cutting capacity150mm

Cutting speed1000mm/min

Dimensions1500 x 1000 x 1000mm

Weight1000kg

Power3kW

Messer Cutting Systems India Private Limited

Coimbatore

Trusted Seller

Trusted Seller9 Years

Manual 450mm Pneumatic Profile Cutting Machine - Blue, Precision Cutting, Durable Design, Easy to Operate

Blade Length450mm

Operation typeManual

MaterialSteel

Weight50kg

Dimensions600x500x1000mm

Warranty1 year

Single Head Cutting Machine with Vertical Bearing System - Aluminium, 6686x890x1285 mm, 400 Volt, 10 Pcs/min Capacity | Adjustable Angles, Lubrication System, Support Pins for 45 & 90 Degrees

Price: 385000.00 INR/Unit

MOQ1 Unit/Units

ColorSTANDARD

Product TypeSPM

General UseUPVC AND ALUMINIUM PROFILE CUTTING MACHINE

MaterialOther

TypeOther

Capacity10 Pcs/min

Gray Aluminium Profile Cutting Machine By Alptech International Private Limited

Price: 350000 INR/Unit

MOQ1 Unit/Units

ColorGray

Product TypeALUMINIUM PROFILE CUTTING MACHINE

General UseIndustrial

MaterialSteel

Weight (kg)250 Kilograms (kg)

Drive TypeElectric

Designer Aluminum Kitchen Profile - Color: Multi

Price: 1000 INR/Kilograms

MOQ10 Kilograms/Kilograms

Usage & ApplicationsKitchen Shutter Handle

SizeDifferent Size

ColorMulti

MaterialAluminium

ShapeRectangular

Surface TreatmentPolished

FAQs Related to Aluminium Profile Cutting Machine

- CNC Machine.

- Hacksaw.

- Metal Brake.

- Circular Saw.

- Jigsaw.

- Metal Shears.

What are the Types of Aluminium Cutting machines?

- Single Head Automatic Aluminium Profile Cutting Machine.

- Double Head Aluminium Cutting Machine.

- Double Head Upvc Cutting Machine.

- Aluminium Cleat Cut Machine.

- Aluminium Section Cutting Machine.

What are the Advantages of Aluminium Cutting Machine?

Which cutting method is suitable for cutting Aluminium?

- CNC Machine.

- Hacksaw.

- Metal Brake.

- Circular Saw.

- Jigsaw.

- Metal Shears.

- Single Head Automatic Aluminium Profile Cutting Machine.

- Double Head Aluminium Cutting Machine.

- Double Head Upvc Cutting Machine.

- Aluminium Cleat Cut Machine.

- Aluminium Section Cutting Machine.

How does Aluminium Cutting Machine work?

50x35mm Aluminum Profile (Edge) - High Purity Metal, Rectangle Shape | White Color, Ideal for Electronics Applications

Price: 376 INR/Piece

MOQ5 Piece/Pieces

ColorWhite

MaterialMetal

ShapeRectangle

PurityHigh

ApplicationElectronics

Aluminium Cutting Services - Long Length, Max Cutting Width 200mm, Green Color | High Speed AC Motor, PLC Controlled, Timely Execution

Price: 5 INR/Piece

MOQ200 Piece/Pieces

Product TypeCutting machine

General UseAluminium cutting services

MaterialOther

TypeVertical, Horizontal, Turning Center, CNC Router, Other

Capacity500 Kg/hr

Weight (kg)500 Kilograms (kg)

Automatic Aluminium Profile Cutting Machine - 350mm Blade Size, Blue Color, Pneumatic Drive, Semi-Automatic Cutting, Water Chiller Cooling System, Environmental Friendly

Price: 325000.00 INR/Unit

MOQ1 Unit/Units

ColorBlue

Product TypePipes Cutting Machine

General UseIndustrial

MaterialAluminum

Weight (kg)350kg Kilograms (kg)

ComputerizedNo

View More

Good Quality Double Head Aluminium Profile Cutting Machine

Price : 850000.00 INR

Aluminium Profile Cutting Machine Blade Size: 450Mm

Price : 575000.00 INR

Mild Steel Profile Cutting Services - Offline Application For Industries | High Performance Solutions

MaterialMild steel

Cutting methodPlasma cutting

Cutting thicknessUp to 25mm

Cutting shapeCircular

Cutting diameterUp to 2 meters

Power sourceElectric

Aluminum Profile cutting Machine

MaterialSteel

Dimensions1000x1500x1200mm

Cutting Capacity60mm

Motor Power3kW

Cutting Speed30m/min

Control SystemCNC

High Efficiency Aluminum Cutting Machine - 220V, 750W | Electric Drive, High Precision Cutting, Easy Operation, Durable Design, Smooth Cuts

Price: 1.0 USD ($)/Unit

MOQ1 Unit/Units, Unit/Units

Product TypeAluminium Cutting Machine

General UseUsed for cutting aluminium

Drive TypeElectric

Voltage220 Volt (v)

Aluminum Profile-Cutting Machine - 230 Watts, 18000 RPM Spindle Speed, Easy PLC Control, Lightweight 37 kg

Price: 42000 INR/Piece

MOQ3 Piece/Pieces

Product TypeAluminium Profile Cutting Machine

General UseIndustrial Use

MaterialAluminum

Weight (kg)37 Kilograms (kg)

ComputerizedNo

AutomaticYes

Rapi Cut 750 Semi Automatic Alloy Cutting Machine - Steel, 600x1000x1200 mm, White | Pneumatic Clamping, 300-350 mm Blade, 3200-2600 RPM Cutting Speed, Water Chiller Cooling System, Manual & Auto Feed Mechanism

Price: 290000 INR/Unit

MOQ1 Unit/Units

ColorWhite

Product TypeAlloy Section Cutting Machine

General UseIndustrial Use

MaterialSteel

Capacity6000-14000 pcs

Weight (kg)350 Kilograms (kg)

Single Head Cutting Machine - 550mm Blade Diameter, 160x300mm Max Cutting Section | Robust Structure, Hydraulic-Pneumatic Damping, Spray Mist Cooling System, Precise 90-Degree Cutting

Working air pressure0.5~0.8mpa

Air consumption120L/min

Input voltage3-phase, 380v, 50hz

Input power3.0kW

Saw Blade Diameter550mm

Saw blade speed2800r/min

View More

Aluminium Profiles Precision Double Mitre Cutting Machine

Price Trend : 600000.00 - 1600000.00 INR

Automatic Aluminium Profile Cutting Machine

Price Trend : 600000.00 - 800000.00 INR

End Milling Machine for Aluminum and PVC Win Door (LSDX04-200)

MaterialSteel, Aluminum

Dimensions1000X800X1500Mm

Power3Kw

Weight500Kg

SpeedVariable

Accuracy+/-0.1Mm

Dealer & Stockist of MS C 45 Plate

MaterialMild Steel

DimensionsVariable

ThicknessVariable

Surface FinishVariable

GradeC45

StandardsIS

Aluminum Profile Cutting Machine

MaterialMetal

ApplicationDoor Making

UsageMetal Sheets

AutomationAutomatic

Power SourceElectric

Cutting TypeProfile

Aluminum Profile Cutting Machine

MaterialSteel

Dimensions10ft x 5ft x 3ft

Power220V

Weight500kg

Cutting Speed1000mm/min

Motor Power3kW

View More

Aluminum Single Head Cutting Machine

Get Best Deal

Z4 Series Industrial DC Motor - 1.5kw-1500kw Output Power, 200-3000 RPM Speed, Green Color | Drip-Proof, High Efficiency, CE Certified

Price: 1000/Piece

MOQ1 Piece/Pieces

ColorGreen

Voltage400/440

Ambient Temperature40C Celsius (oC)

Rated Voltage160/220/330/400/440/550/660

PressureModerate Pressure mpa

Output Power1.5kw-1500kw

Aluminium Profile Cutting Machine - Fully Automatic, 14'' Spindle, 3700 RPM, Cutting Angles 90°/45° | Automatic Cut, Durable Build, Easy Operation, Increased Efficiency, Precise Cuts

MaterialSteel

Cutting angle90/45

Spindle rpm3700

Air pressure6 to 8 bar

Power440 / 220 AC

DimensionsNA

View More

Aluminium Profile Cutting Machines

Price : 350000 INR

Aluminum Cutting Machine - Color: Black

Price: 90000 INR/Piece

MOQ1 Piece/Pieces

Product TypeAluminum Cutting Machine

MaterialSteel

TypeBar Cutting Machine

ComputerizedNo

AutomaticYes

Cutting FunctionSemi Automatic

Popular Aluminium Profile Cutting Machine

Aluminium Cutting Machine Overview

Types Of Aluminium Cutting Machine

How To Choose Aluminium Cutting Machine?

Advantages Of Aluminium Cutting Machine

Client Testimonials & Reviews

BhupendraYadav

CNC SOLUTIONS

We are pleased to associate with tradeindia (Indiaa s largest B2B portal) for online promotion of our products. Such online platform will help us a lot for market reach, Brand-promotion and New Market Exploration. We are very happy to become a member of tradeindia.com. All the best an efficient team tradeindia for many more milestones

Tradeindia.com provided excellent quality services and proved to be very helpful to expand our business to reach new heights through their inquires. We are able to generate sales from the actual users, large companies and foreign companies for our 'Pioneer' All geared Lathe Machines. We got prompt replies and personal visits from tradeindia executives from time to time. We recommend other companies to join tradeindia.com, in order to grow their business in India as well as Foreign Countries. Their Mobile App is also very useful for potential buyers. Thank you tradeindia.com.

Aluminium Profile Cutting Machine Price List

This Data was Last Updated on 2025-09-05

Aluminium Profile Cutting Machine Manufacturers | Suppliers in India

Company Name | Member Since |

|---|---|

Janak Enterprises Bhavnagar, India | 15 Years |

Foshan Shunde Kingtool Aluminum Processing Machinery Co., Ltd. Foshan, China | 14 Years |

Zenith Engineering And Equipments Private Limited Vadodara, India | 11 Years |

Ss Engineers And Consultants Private Limited Rajahmundry, India | 9 Years |

Messer Cutting Systems India Private Limited Coimbatore, India | 9 Years |

Glasswin Engineering Pune, India | 6 Years |

Taalin Machinery & Robotics Pvt. Ltd. Greater Noida, India | 5 Years |

Atlas Machine Ghaziabad Ghaziabad, India | 4 Years |

Alptech International Private Limited Thane, India | 3 Years |

Ahead Technology Solutions Pune, India | 2 Years |

Upcoming Tradeshows

ENGIMACH 2025

Wed, 03 Dec, 2025 - Sun, 07 Dec, 2025

China (Guzhen) International Lighting Fair 2025

Wed, 22 Oct, 2025 - Sat, 25 Oct, 2025

8th INTERNATIONAL SOAP & DETERGENT EXPO 2026

Thu, 26 Feb, 2026 - Fri, 27 Feb, 2026

YARNEX - Mumbai 2025

Thu, 27 Nov, 2025 - Sat, 29 Nov, 2025

Spectra Expo 2026

Thu, 05 Feb, 2026 - Sat, 07 Feb, 2026

INDIA GREEN ENERGY EXPO 2026

Wed, 29 Jul, 2026 - Fri, 31 Jul, 2026

Indian Ceramics Asia 2026

Wed, 28 Jan, 2026 - Fri, 30 Jan, 2026

PharmaTech Expo & LabTech Expo 2026

Fri, 19 Dec, 2025 - Sun, 21 Dec, 2025

Pune Expo 2025

Wed, 10 Dec, 2025 - Fri, 12 Dec, 2025

ET TECH X 2025

Thu, 11 Dec, 2025 - Sat, 13 Dec, 2025

Popular Categories